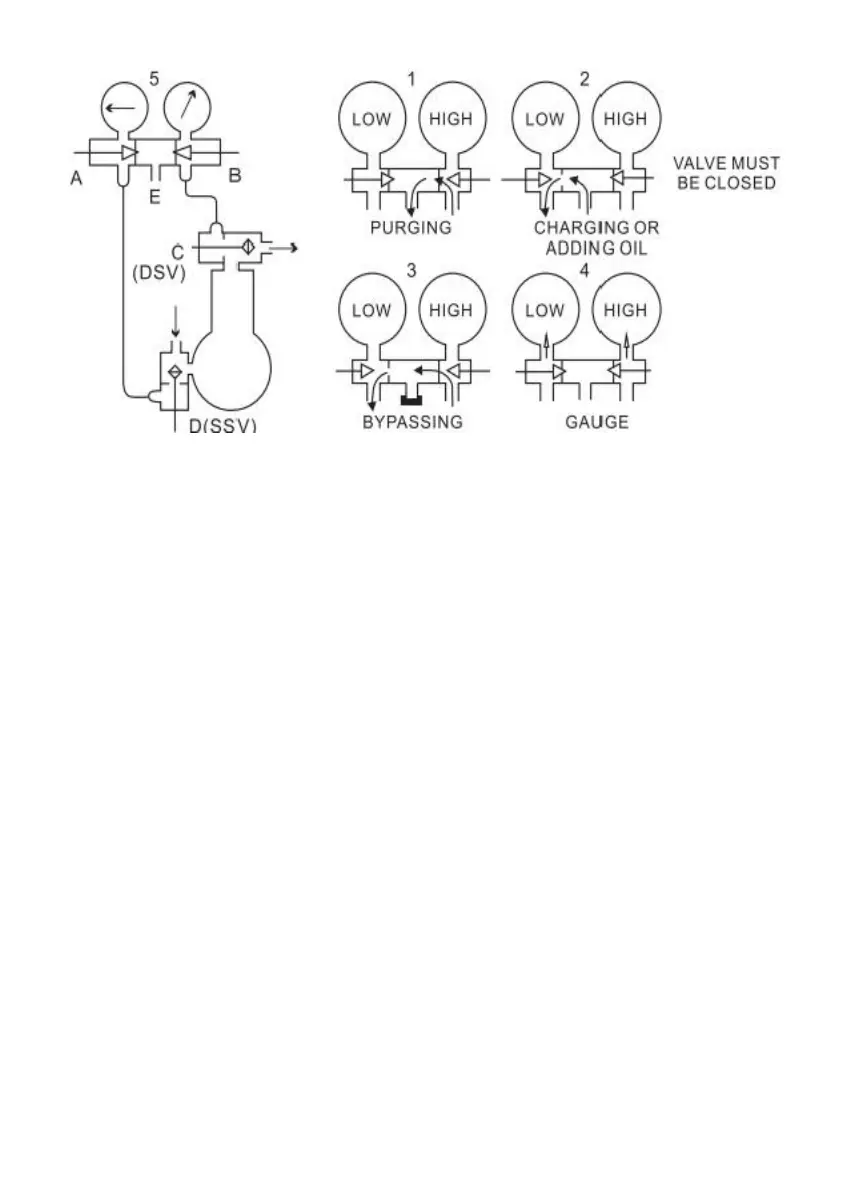

Lines from the manifold are attached to the SSV at D and should be left

one to two turns lose while the line to the DSV should be tightened. Then

open both of the manifold valves at A and B 1/4 turn to 1/2 turn and cap

the middle opening,E.

Now turn the(DSV)Cstemin1'8 to 1/4 turn for just a moment(crack the

valve).A surge of high-pressure refrigerant will then rush through the lines

and the manifold and purge to the atmosphere at the loose connection at

D the SSv. This connection may then be tightened.Purging is necessary

to remove air and moisture from the manifold and lines. NOTE: Purging

must be held to a minimum to avoid damage to the atmosphere.

Carefully test for leaks while the manifold and its lines are under high

pressure. Correct any leak immediately.

Various service and testing operations may be performed after the

testing manifold has been installed:

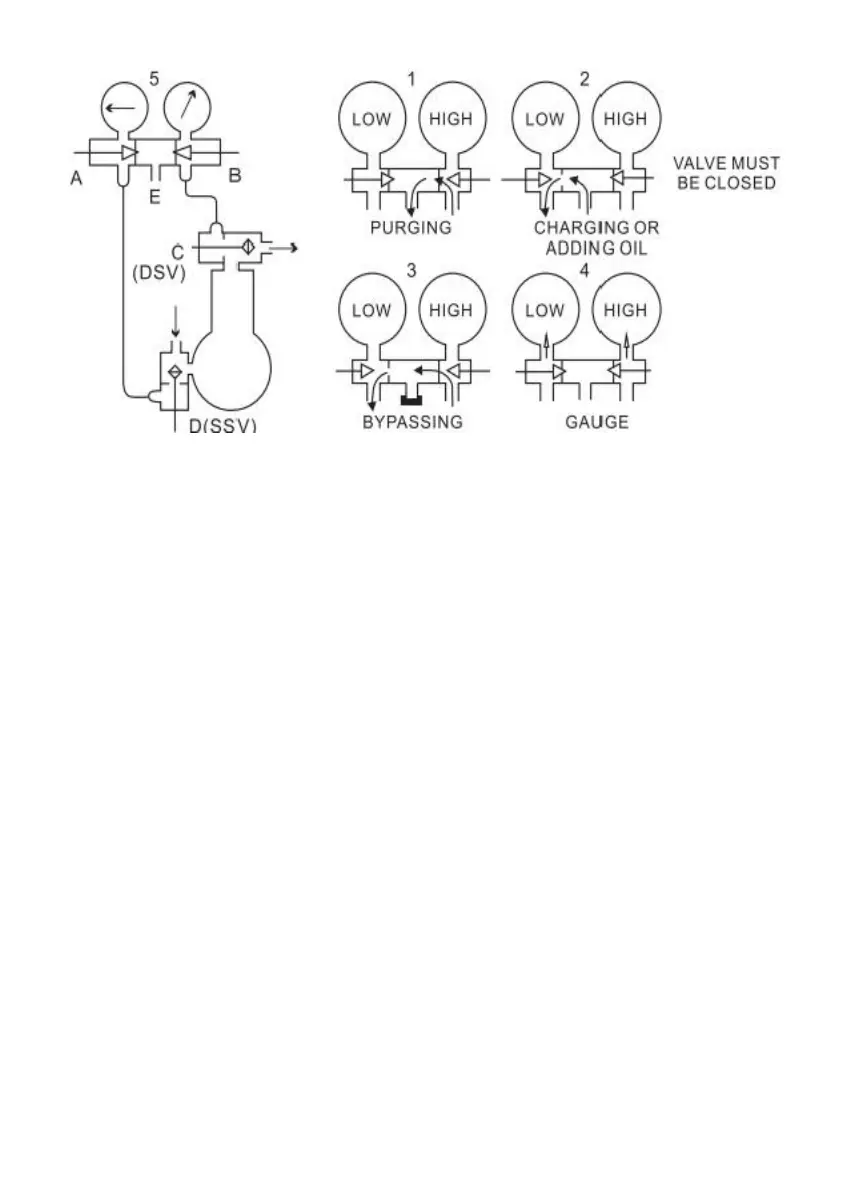

1. Observe operating pressures by:

Closing valve A by turning all the way in.

Closing valve B by turning all the way in.

Cracking open back seat of valve C.

Cracking open back seat of valve D.

2. Charge refrigerant into system by:

Connecting refrigerant cylinder to E (vapor only).

Opening valve A.

Closing valve B.

Closing front seat of valve D slowly.

3. Purge condenser by:

Closing valve A.

Loading...

Loading...