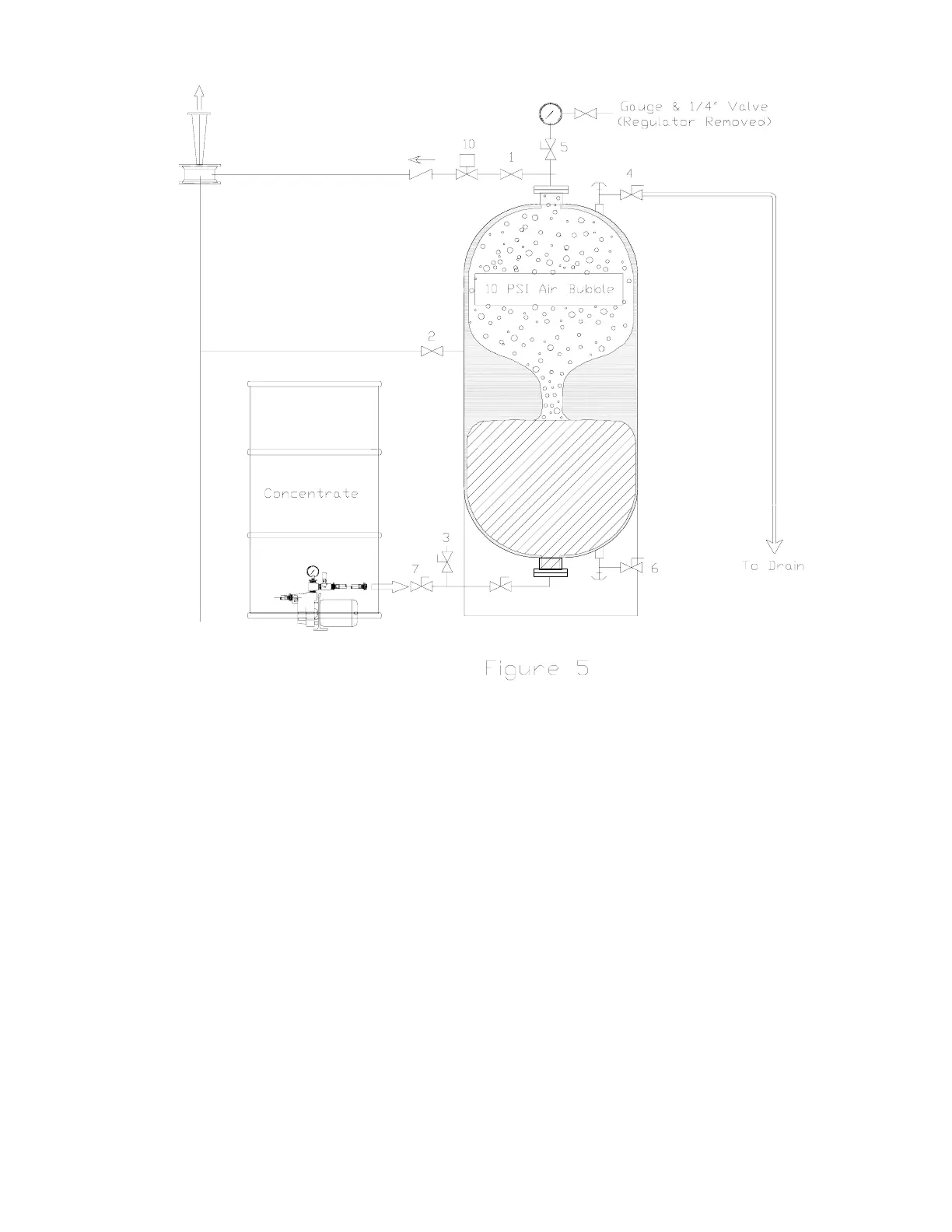

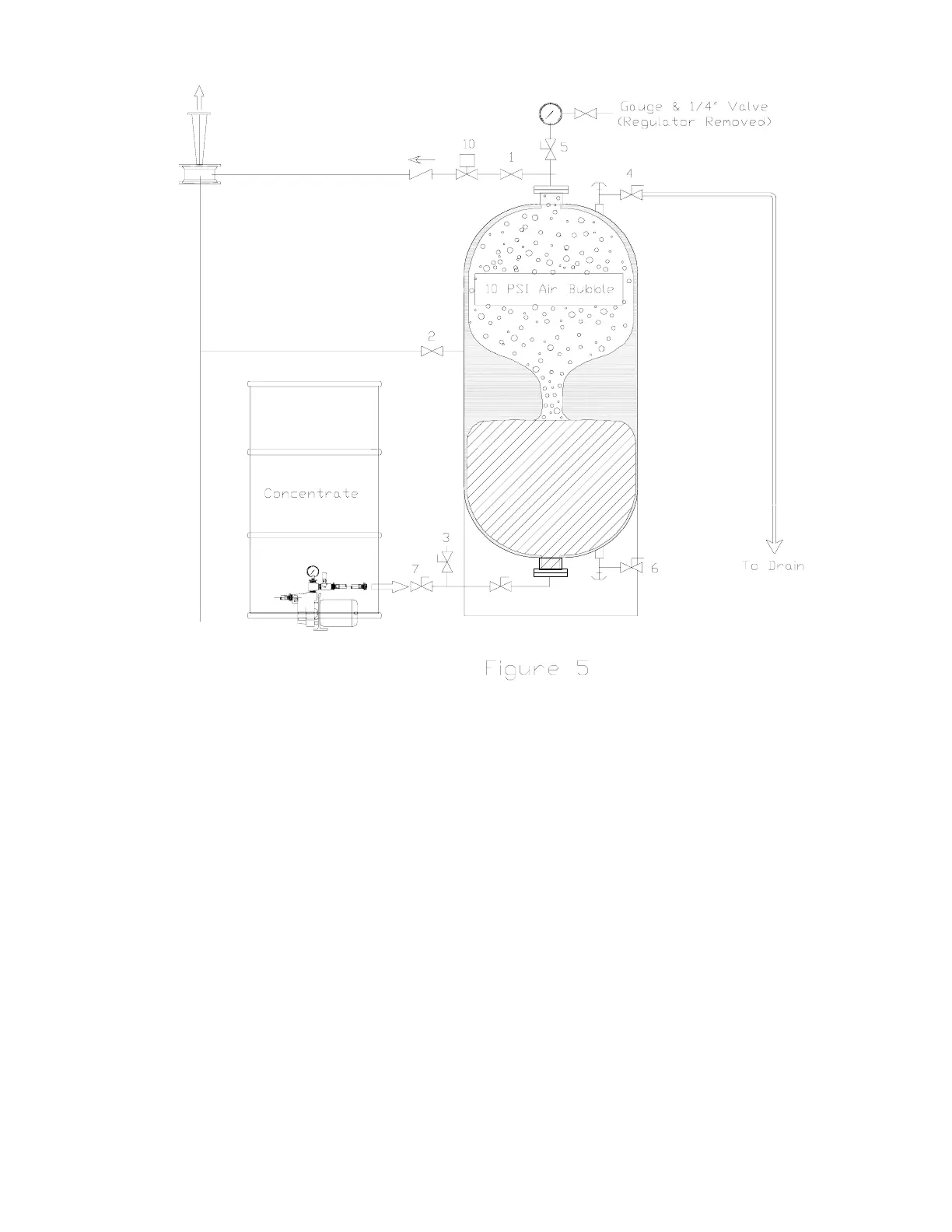

The concentrate displaces the shell water. If tank pressure steadily decreases, it will be necessary to partially

close Valve No. 4 to slow down the discharge of water. If tank pressure steadily increases, it will be necessary

to partially (or fully) open Valve No. 6 to allow the pressure to drop back to 10 PSI. Slowing the pump discharge

will also lower the tank pressure.

When approximately 75% of the nominal charge has been attained, (90% for horizontal tanks), shell water will

stop flowing and the tank pressure will begin to exceed 10 PSI.

Step 10: Partially open ¼” shut off at Valve No. 5 to vent and slowly allow air pressure to drop to 0 PSI while continu-

ing to pump the concentrate to the rated capacity.

IMPORTANT: IF CONCENTRATE OVERFLOWS FROM VALVE N|O. 5, DRAIN BACK SEVERAL GALLONS TO ALLOW

FOR EXPANSION OF AGENT. FILL ONLY TO RATED CAPACITY! OVERFILLING MAY DAMAGE THE BLADDER!

Step 11: Close Valve No. 7, shut off the pump, and remove ¼” valve and gauge assemble from Valve No. 5.

10.0 SIGHT GAUGE PROCEDURE

Step 12: Open Valve No. 3 (also Valve No.’s 8 and 9, if AFFF), and allow sight gauge to fill. Mark level for future

reference. Close sight gauge valves and drain concentrate from tube.

12

Loading...

Loading...