accumulate between the wing feeders and the screen. This buildup can cause wear of the

screen. Should the problem occur, grind off the wing feeders.

Notches

Sometimes it is necessary, during press operation, to have the screw wipe the screens clear of

blinding material. This is best achieved by having notches in the outer edge of the screw.

Fibrous material accumulates in the notches and brushes away slimy material which may be

blinding the screens. Shallow notches (1/16" wide by 1/16" deep, 1-1/2" apart) in the outer

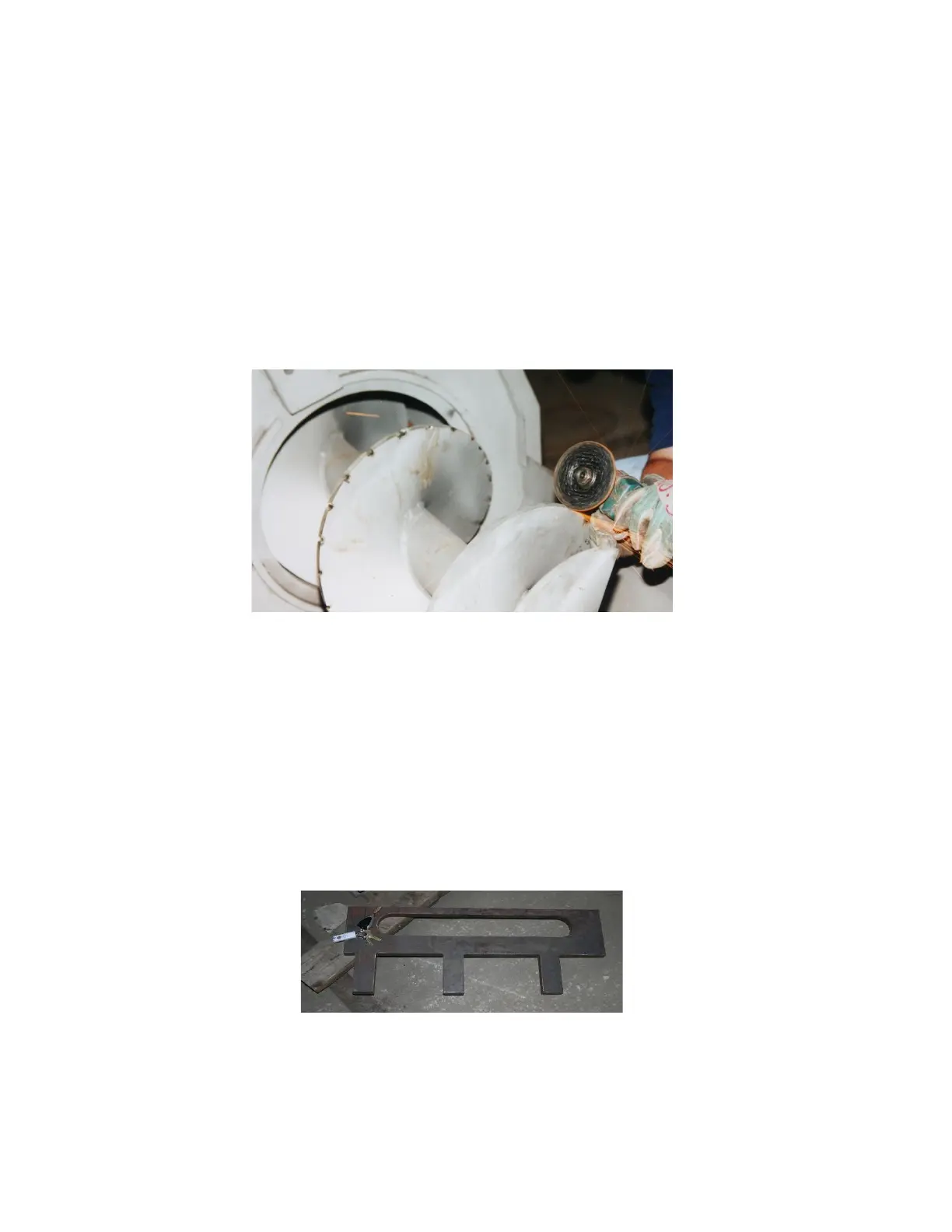

edge of the screw flights work well. Notching is easy to do while in the field, using a grinder

with cutting wheel or a portable band saw. Typically, notching is done from the B-plate to

the second resistor tooth. Many Vincent presses are supplied with notches.

Grinding Notches on Screw Flights

Resistor Teeth

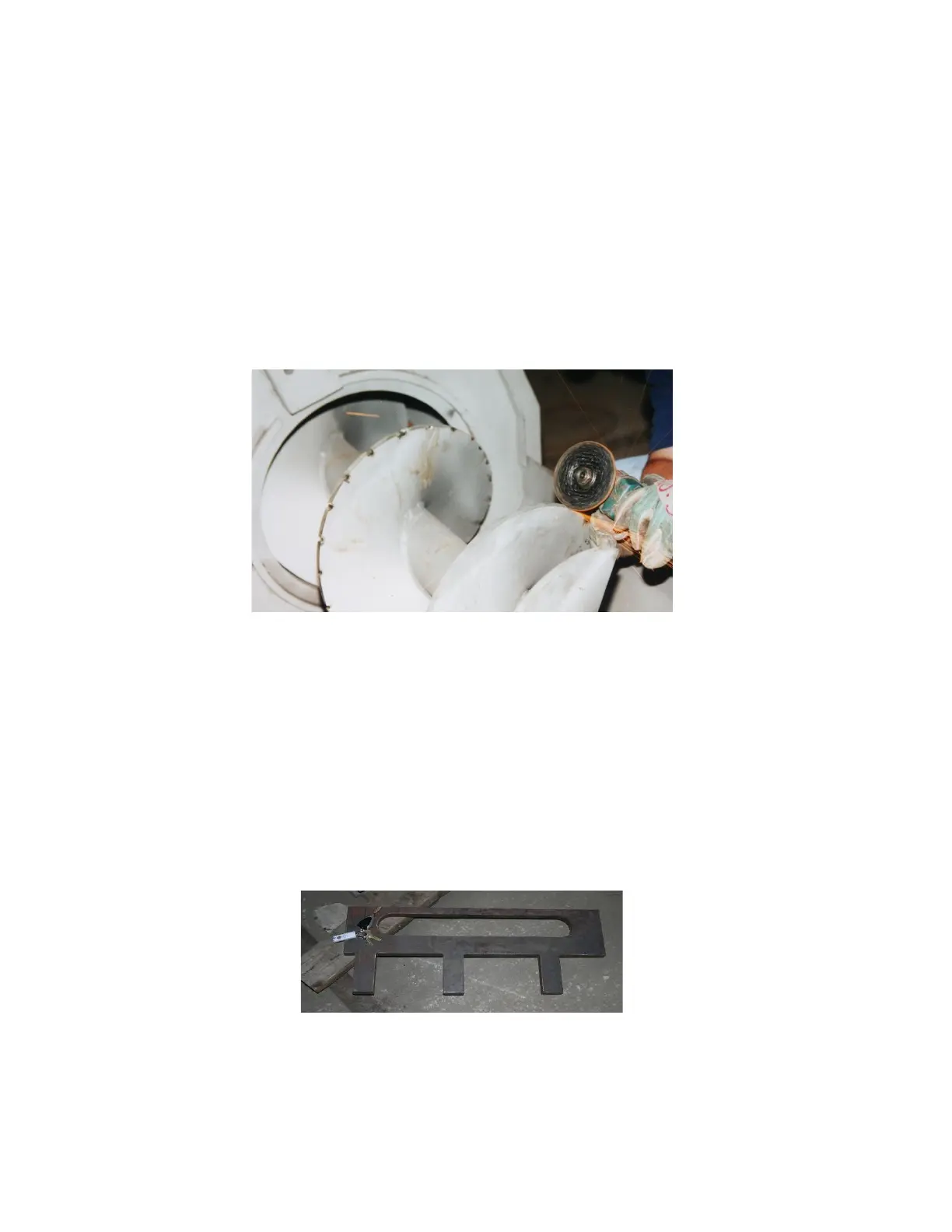

The interrupted screw design press has stationary teeth that protrude into the flow of material

as it passes through the press. These fit into the gaps of the screw where there is no flighting.

They stop just short of the shaft of the screw.

Rarely, the resistor teeth are shortened, usually by half, to increase the capacity of the press.

Removing the teeth altogether will result in co-rotation and jamming.

Occasionally, the teeth are drilled so that fluid can be injected into the press during operation.

Fluids include caustic solution, solvent, hot water, and steam.

KP Resistor Bar with Three Teeth

14

Loading...

Loading...