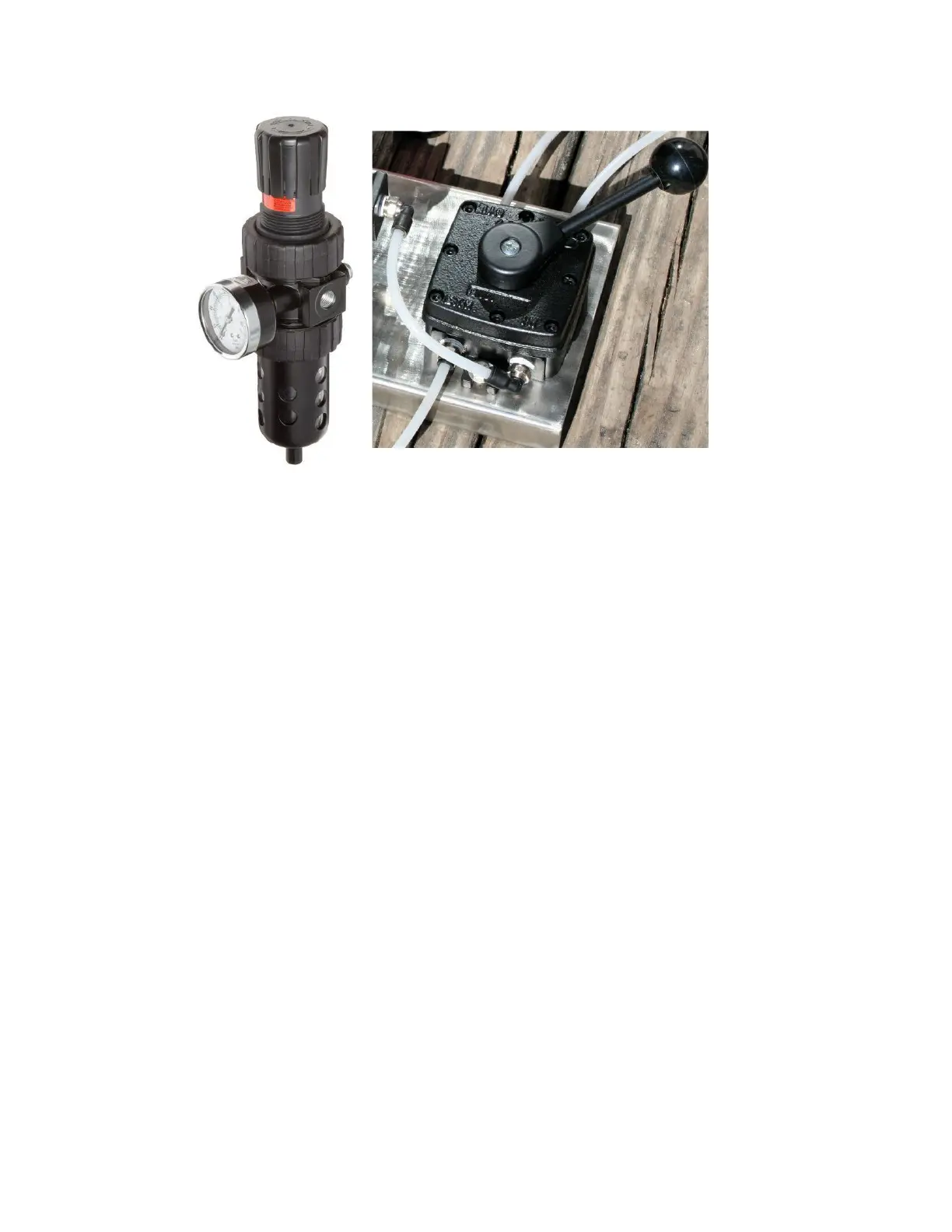

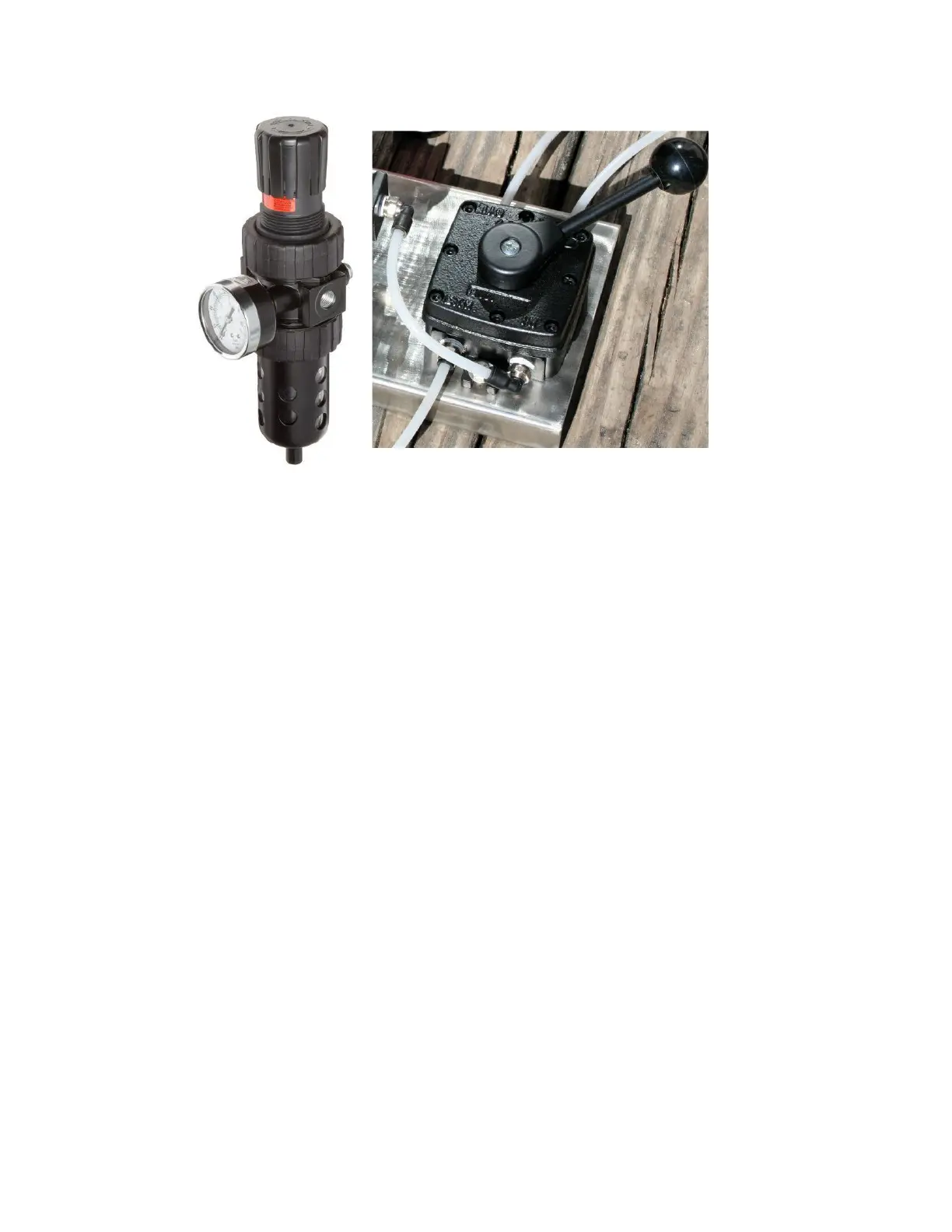

Regulator 4-way Valve

Discharge Cone

The principal adjustment of the press is made with the discharge cone. The cone is the

component at the cake discharge end of the press that acts as a door or stopper plug to restrict

material from leaving the press. The more pressure exerted by the discharge cone, the drier

the cake material will be leaving the press. Also, the motor amps can be expected to increase

with added pressure, and throughput may decrease.

The discharge cone is moved in (actuated) either by an air cylinder or, rarely, by weights.

Typical air cylinder pressures are in the range of 30 to 60 psi. Some materials will press only

in a low range, say 10 to 20 psi. Other materials may press best with a pressure of 60 to 100

psi. Air consumption is minimal in all models, 1 to 2 cfm.

During initial, first-time start up, presses with air cylinder actuators are generally started up

with the discharge cone in the withdrawn position. This will avoid an unnecessary jam.

With the air cylinder models, the discharge cone mechanism can readily be positioned in the

"open" (or withdrawn/"out") position.

Note that with many materials it is necessary to start the press with the discharge cone in the

closed position at low air pressure. Thin or soupy materials, like pumped manure or clarifier

underflow, can tend to purge right through the press if the press is operated with the

discharge cone open [in the withdrawn ("out") position]. However, with materials that are

dry to begin with, such as sawdust or plastic wash tank sludge, it becomes more important to

start with the discharge cone in the open position. This is because these materials may tend

to jam or overload the press. Similarly, high freeness materials, from which the water falls

away freely, will tend to jam in a press. Start the press with the cone open, then close it with

low air pressure initially, when running such materials for the first time.

8

Air to cylinder

Air

Supply

Vent

Loading...

Loading...