DE5110 5

7+($/$50&21752/&$%,1(7

$ODUP &RQWURO 0RGXOH 'HVFULSWLRQ

As the nerve center or the brain of the entire alarm system, this

programmable module includes the hardware and firmware

necessary for managing the system with or without auxiliary

modules - the communicator, zone expander and the siren driver.

It must be stressed, though, that at least one keypad/display unit is

required to set up a workable 8-zone alarm system.

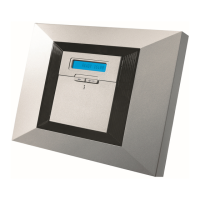

Figure 3.1 The MAESTRO-1600 Control Module

The control module (Fig. 3.1) comes mounted within the alarm

control cabinet. Its printed circuit board is equipped with a socket

for the communicator module (at the left hand edge) and a socket

for the siren driver module (at the right hand edge).

Operating power is supplied from a 16 VAC / 40 VA stepdown

transformer - part of the power pack kit PK-1. The control module

accommodates a voltage regulator and a charger for the backup

battery. Regulated 12 VDC output for the detectors, all the

keypads and other external devices is obtained via an on-board 1A

fuse marked "ACCESSORIES". Two pairs of 12VDC output

terminals are provided, to allow easier connection of a large

number of accessories.

The ALARM relay has changeover (Form 1C) dry contacts rated at

5A/24 Volts, and can be used to activate alarm devices such as

sirens or bells (Fig. 3.7). A jumper marked V-BELL connects the

12 VDC supply to the common (C) contact of the alarm relay, via a

3A fuse marked BELL. With the jumper installed across the two

V-BELL pins, the bell or siren can be wired between the N.O.

contact of the relay and the negative (–) supply terminal.

3RZHU 3DFN .LW 3.

The AC power pack for the MAESTRO-1600 is delivered

separately in kit form, to suit the mains voltage and the particular

regulations in the country of use. The kit includes a step-down

transformer, an AC mains terminal block with a built-in fuse holder

and a 0.3 A fuse, mounting hardware and a terminal identification

sticker. As an essential part of the alarm control system, the power

pack must be installed in the metal cabinet (Fig 3.2) and wired

accordingly (Fig. 3.3).

A. Align the transformer mounting ears with the 2 stand-off screws

on the rear wall of the case and let the screws pass through the

holes. Mount a flat washer, a lock washer and a nut (in this

order) on each screw and tighten both nuts.

B . Place AC mains terminal block with its ground lug over the

stand-off grounding screw, and the hole nearest to the fuse

holder over press nut. Pass a screw (supplied in the kit)

through that hole and thread it into press nut. Tighten screw

well. Put a lock washer and a nut over the stand-off grounding

screw and tighten nut to fasten ground lug to the case.

C. Remove the paper backing from the terminal identification

sticker and attach the sticker to the rear wall of the case, as

close as possible to the AC terminal block.

Loading...

Loading...