R750EU5 - IE3 - TE4 - IE4 - ISE4

English 48 Ed.8 / 10-2012

GB

3- Prepare a container of appropriate

capacity.

4- Loosen the screw (E).

Do not loosen high-pressure pipe

unions of the supply circuit (COMMON

RAIL system).

5- Operate the pump (F) manually to

eliminate air from the circuit.

6-Check that a ow of clean fuel contai-

ning no air bubbles is coming out of the

bleeder screw (E).

Be careful to ensure that the fuel in the

lter does not drain completely out.

If it does, remove it (see “Fuel lter

replacement.”), ll it manually and then

repeat the bleeding operation.

7- Tighten the screw (E).

8- Wipe out the fuel residues before star-

ting the engine.

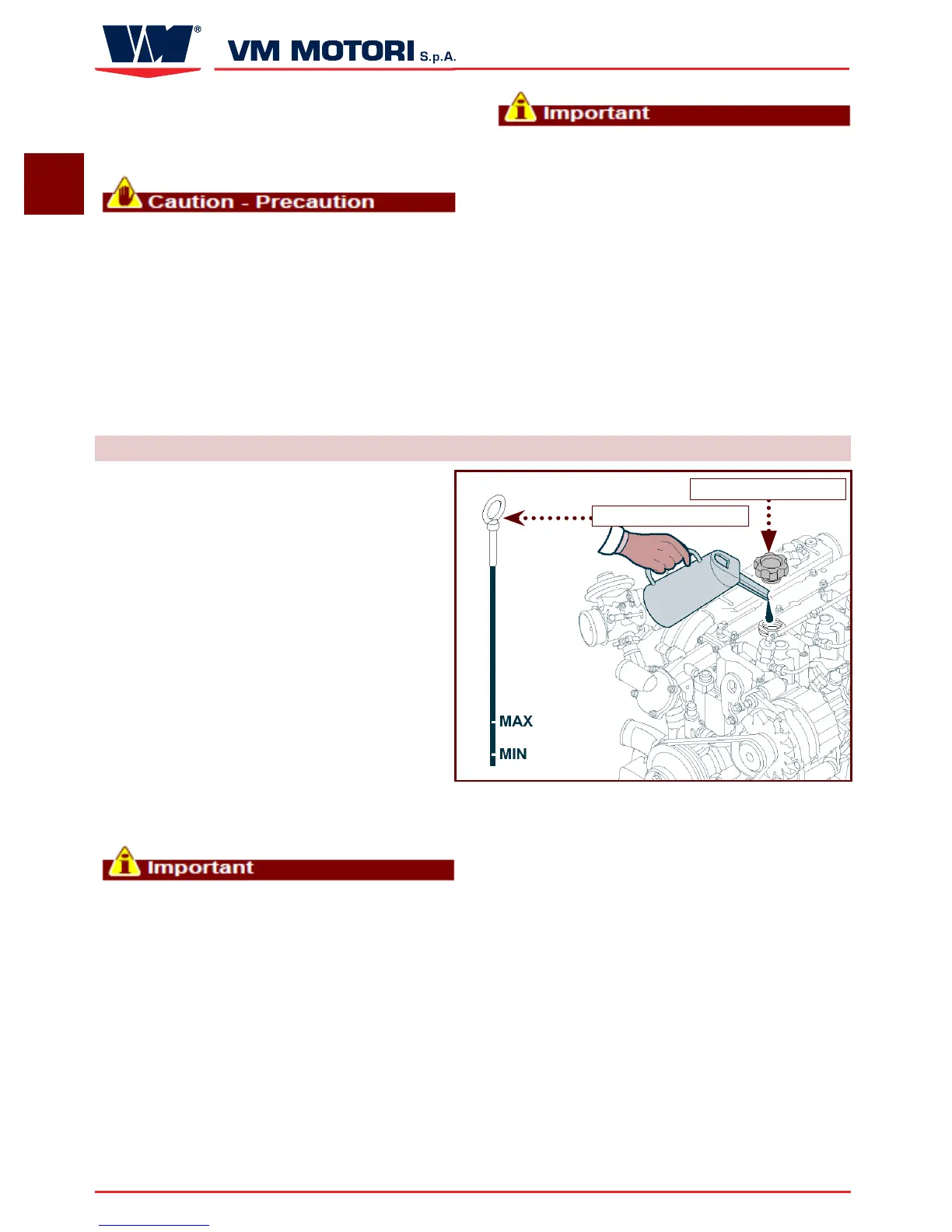

ENGINE OIL LEVEL CONTROL

Filler Cap (M)

Oil Dipstick (L)

Follow the procedure below.

1- Start the engine and bring it to the ope-

rating temperature (70÷80 °C).

2- Turn off the engine and remove the

ignition key.

3- Place the engine on a perfectly level

surface.

4-Wait a few minutes so that all the oil will

ow into the sump.

5-Remove the dipstick (L) and check the

oil level.

6- Top up, if necessary, from plug (M). As

for the oil quantity, see “Technical data ”.

The oil level should be included

between the minimum and maximum

marks. Do not mix oils of different

brands or with different features. (See

“Recommended lubricants”)

Loading...

Loading...