4.22 Cooling system: checking frost protec‐

tion and coolant level

Note

♦

The water used for mixing has a major influence on the ef‐

fectiveness of the coolant. Because the water quality differs

from country to country and even from region to region, the

quality of the water to be used in the cooling system has

been specified accordingly. Distilled water fulfils all require‐

ments. Therefore, always use distilled water when mixing

coolant for topping up or when renewing coolant.

♦

Use only coolant additives as per ⇒ Electronic parts cata‐

logue (ETKA). Other coolant additives may reduce corrosion

protection substantially. The resulting damage could lead to

loss of coolant and subsequent severe damage to the motor.

♦

Mixed in the proper proportions, coolant inhibits frost and

corrosion damage as well as scaling. Additives also raise the

boiling point of the coolant. Therefore, the cooling system

must be filled all year round with a coolant additive.

♦

Because of its high boiling point, the coolant improves motor

reliability under heavy loads, particularly in countries with

tropical climates.

♦

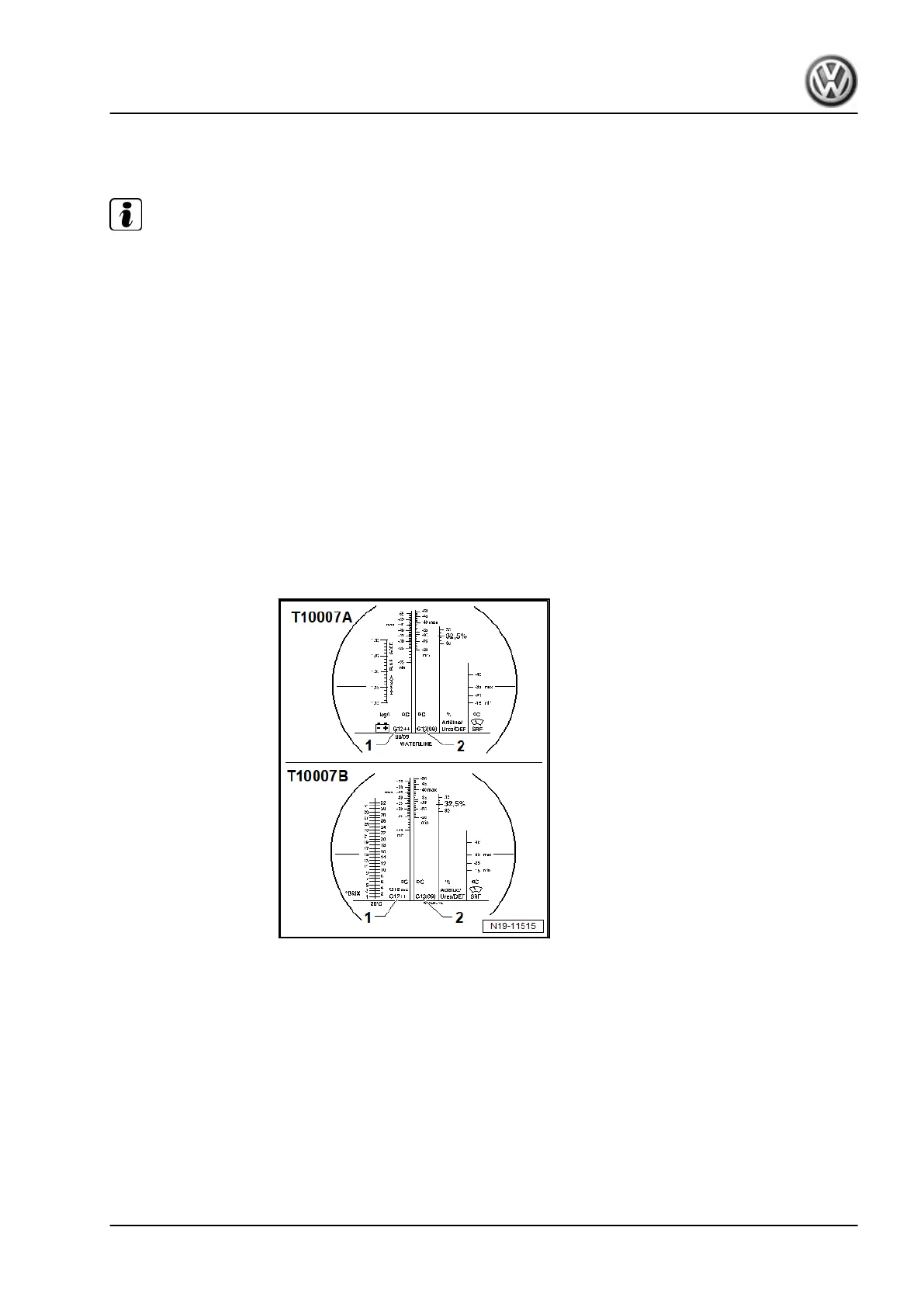

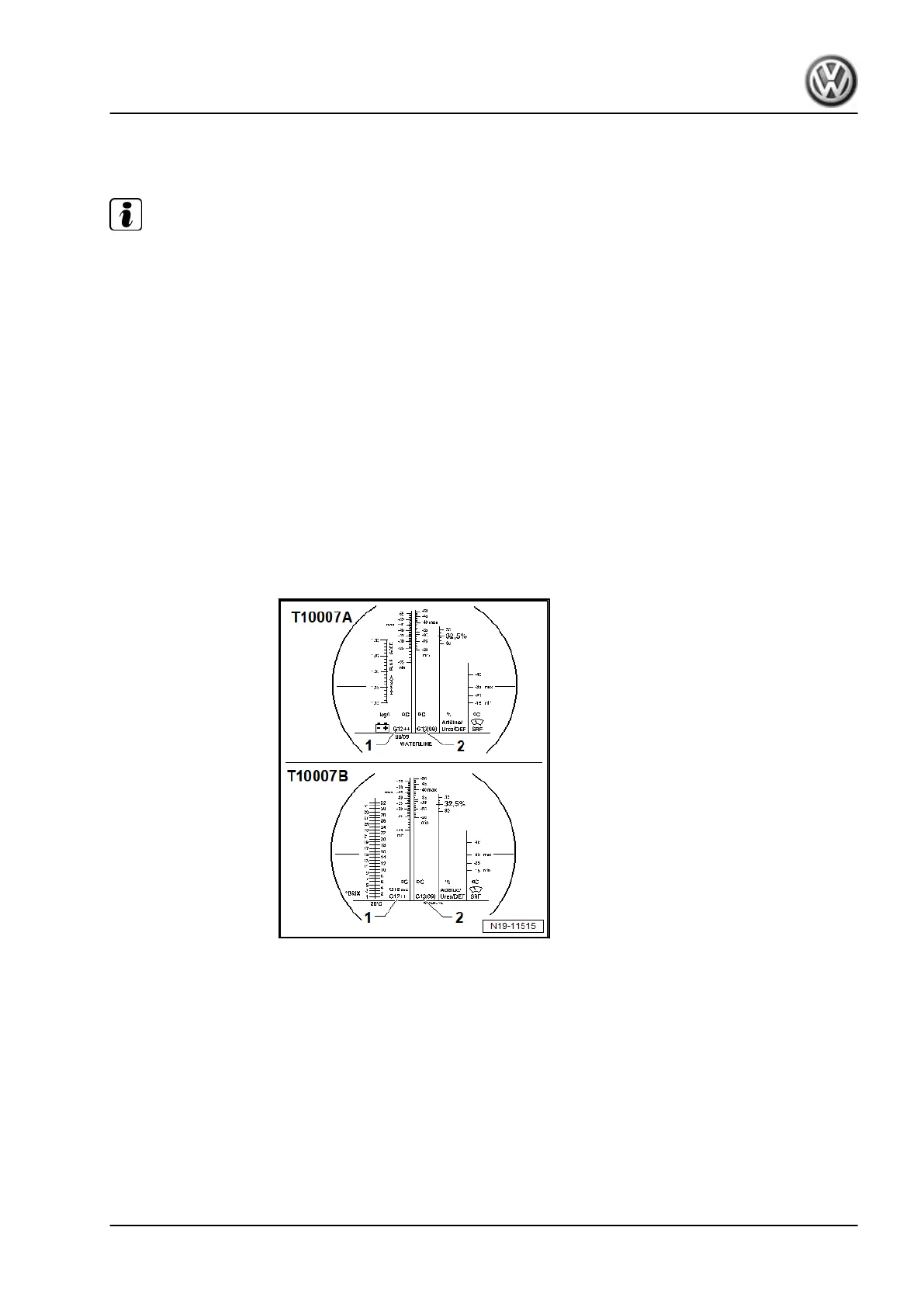

The refractometer -T10007A- or refractometer -T10007B-

must be used to determine the current anti-freeze value.

♦

The scale -1- of the refractometer is calibrated for the cool‐

ant additives G12++ and G12evo.

♦

The scale -2- of the refractometer is calibrated for the cool‐

ant additive G13.

♦

If it is not possible to ensure that the same type of coolant

additive is filled: always determine anti-freeze protection us‐

ing the scale for G13.

♦

Anti-freeze protection must be guaranteed down to -25°C as

a minimum and, in countries with arctic conditions, down

to approx. -36°C. Increasing the anti-freeze protection is

permissible only if climatic conditions require stronger anti-

freeze protection. It may, however, be increased only to a

maximum of -48°C. Otherwise, the cooling effect will be im‐

paired.

ID.4 2021 ➤

Maintenance - Edition 12.2020

4. Descriptions of work 45

Loading...

Loading...