Service and maintenance

Dump body 153

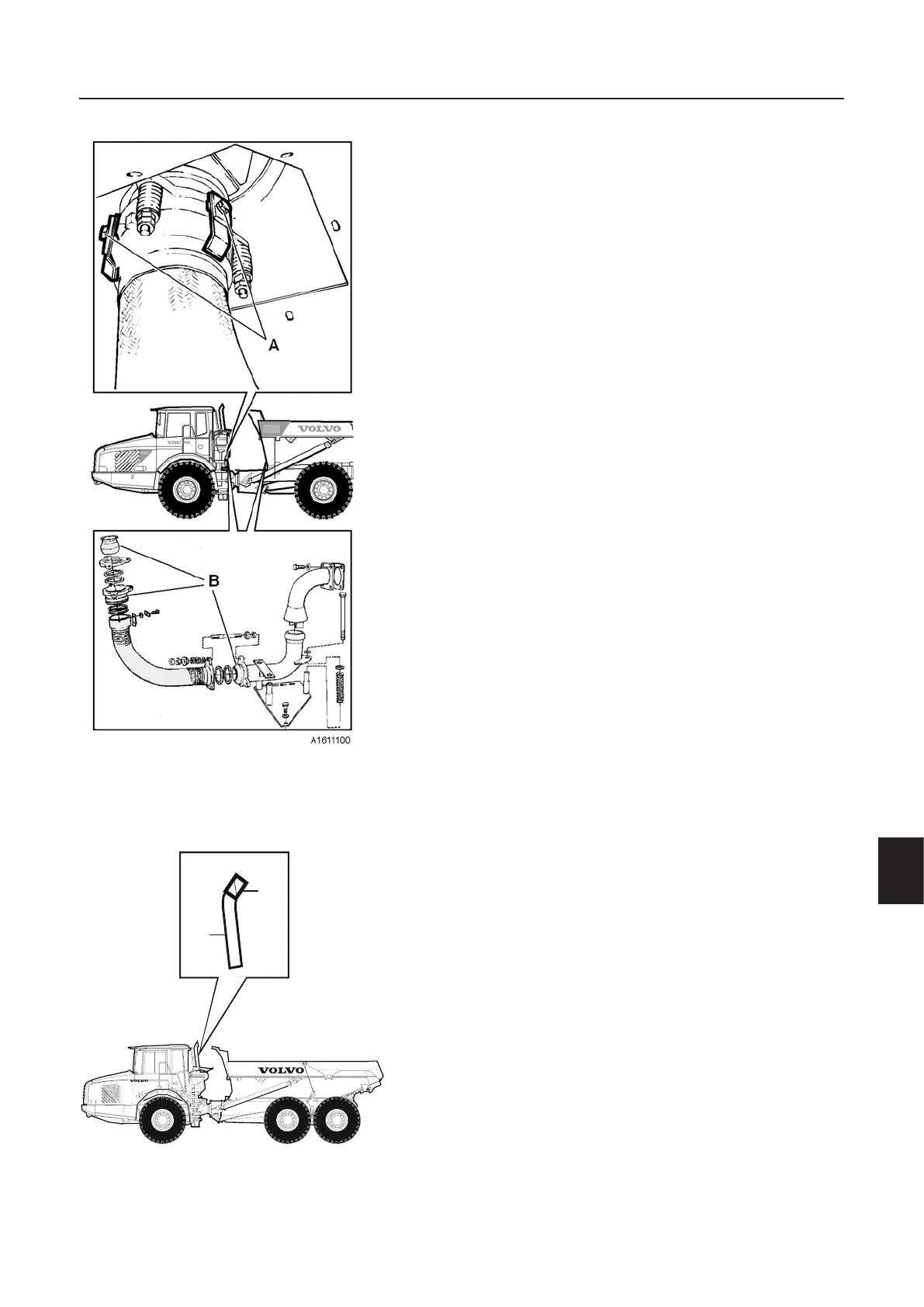

Exhaust heated dump body

(optional equipment)

In order to prevent excavated material from freezing to the body,

the machine can be equipped with a flexible tube between the

tractor unit and the dump body, so that exhaust gases from the

engine can be used for warming up the dump body. The flexible

tube is provided with an over-load protection (A).

If the tube works loose:

1 Slacken the bolts for locking tabs (A).

2 Reposition the tube.

3 Tighten the bolts.

Maintenance of exhaust flexible tube

Clean and lubricate the marked parts (B) every 1000 hours to

make sure the function is operational in case the trailer unit might

overturn.

Lubricate the surfaces with some lubricant.

NOTE! It is important that the lubricant is allowed to dry

properly (for at least 20 minutes) before the exhaust-pipe and

the flexible exhaust tube are joined together.

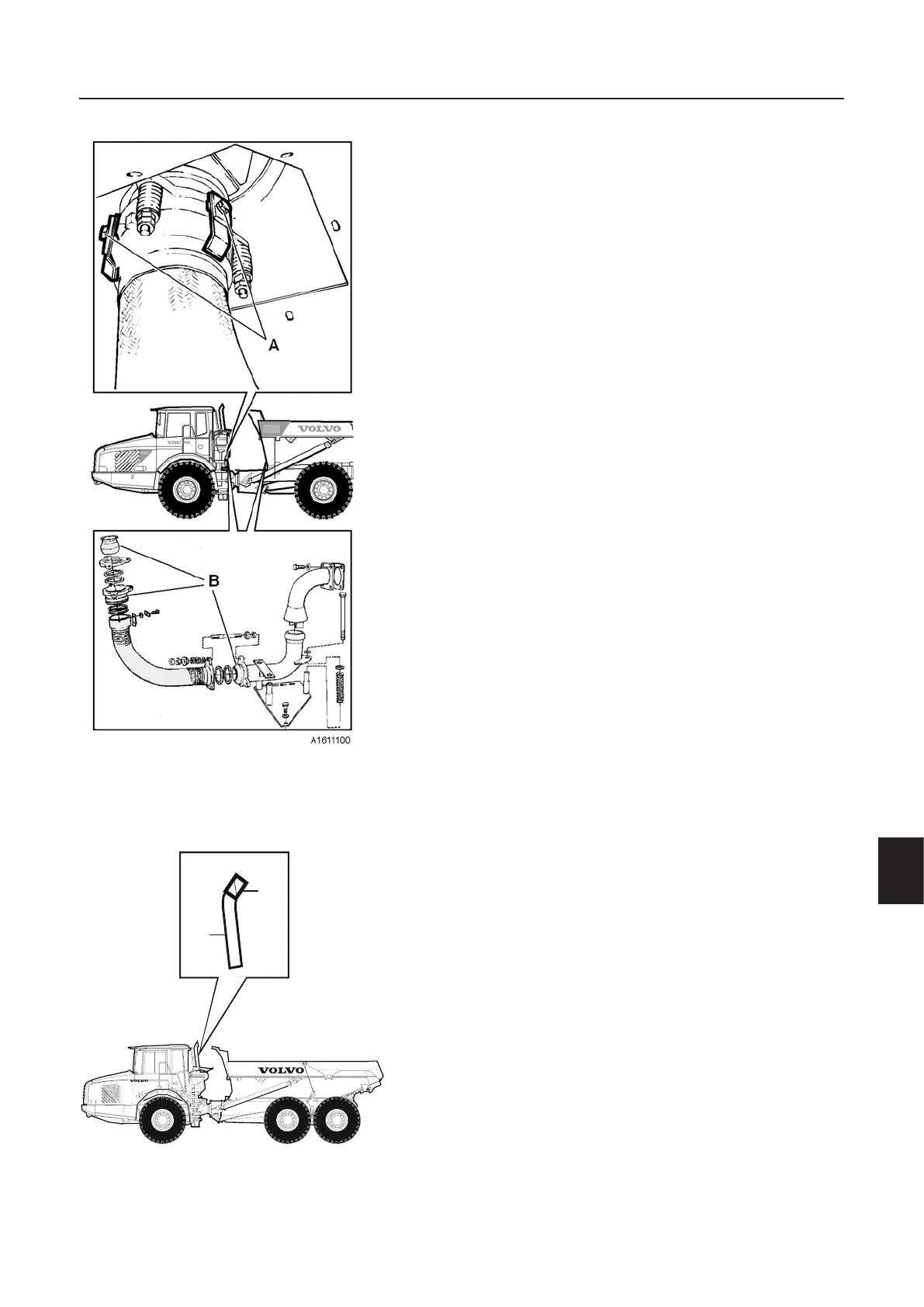

It is important that the engine has the correct back pressure in the

exhaust system.

The exhaust pipe (A) must be left in place and provided with a pipe

end (B), which is provided with a restriction.

A Bolts for lock plate

B Surfaces to be cleaned and lubricated

1

47

B

A

A Exhaust pipe

B Pipe end with restriction

Loading...

Loading...