Service and maintenance

Lubrication and service chart 155

Lubrication and service chart

Greasing bearings

Lubrication is an important part of preventive maintenance. The

service life of bushings, bearings and bearings pins can be

extended considerably, if the machine is lubricated in a correct

way. A lubrication chart makes lubrication work easier and reduces

the risk of forgetting greasing points.

Lubrication has two main purposes:

– To supply grease to the bearing to reduce wear between the pin

and the bushing.

– To replace old, dirty grease. The grease stored inside the outer

seal collects dirt and water, and prevents them from penetrating

into the bearing.

Therefore grease the vehicle at the recommended intervals. Pump

2–3 strokes or until clean grease comes out and becomes visible

by the bearing. Plain bearings should be greased until clean

grease is forced out.

Wipe off grease nipples and the grease gun before greasing

to avoid introducing sand and dirt particles with the grease.

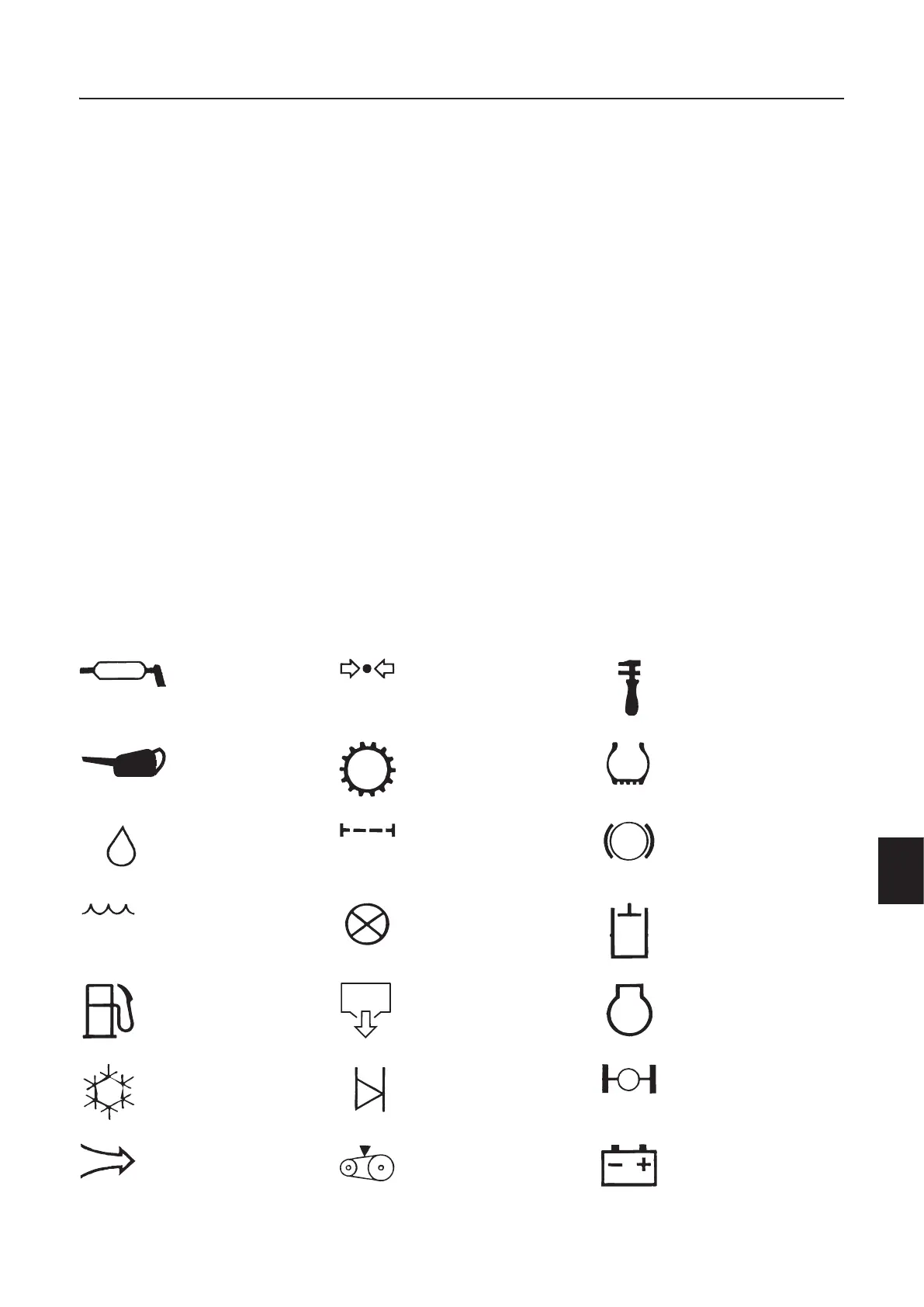

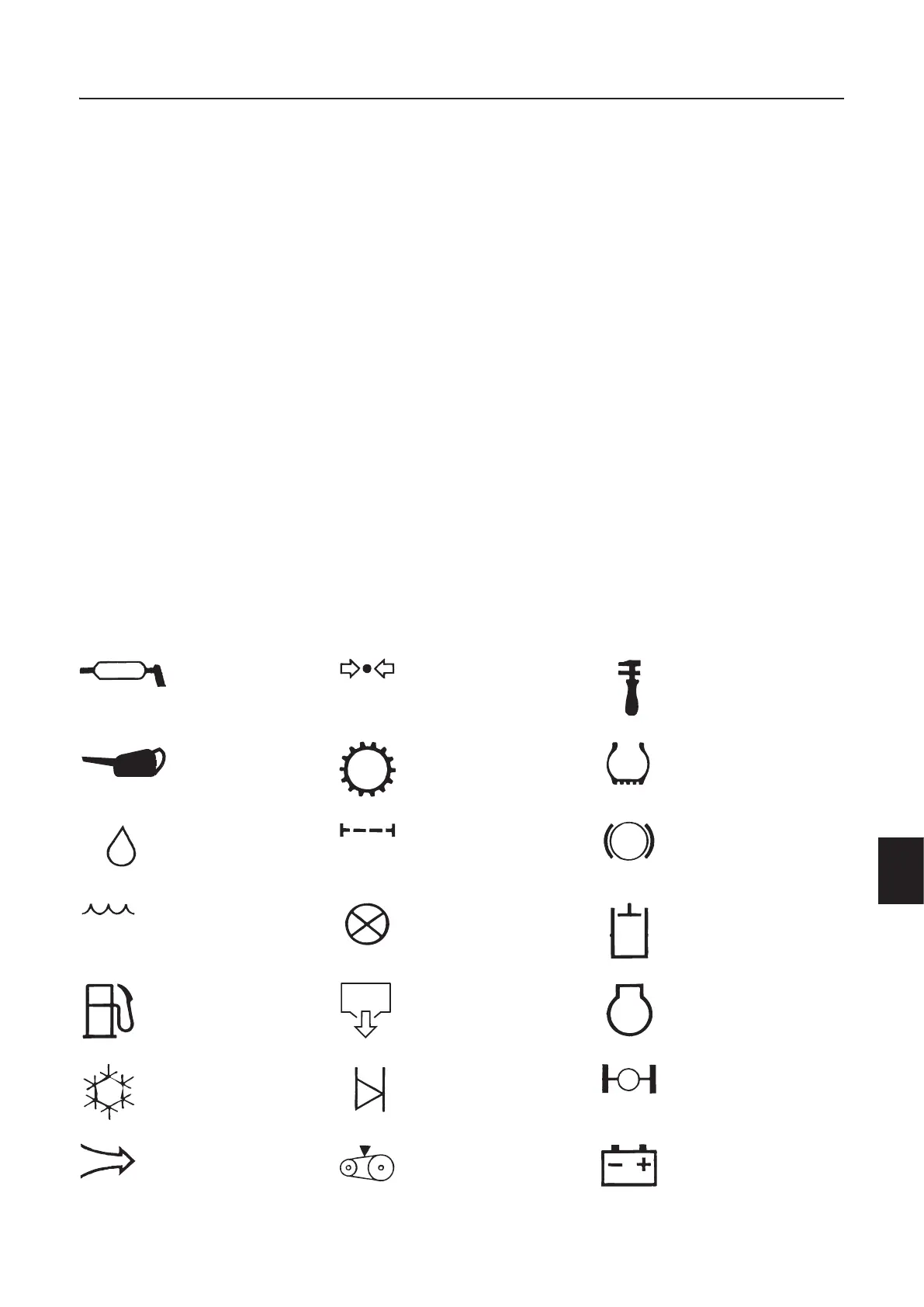

Symbol key for “Lubrication and service

chart”

These standard symbols are used in the Lubrication and service

chart, see the adjacent table.

Lubrication point,

grease

Pressure Maintenance/

Engineer

Lubrication point, oil Transmission Tyres

Oil/liquid Filter Brake

Water Control lamp Hydraulic system

Fuel Draining Engine

Anti-freeze Level check Differential and hub

reduction gear

Air Belt tension Battery

Loading...

Loading...