Group 21

Reconditioning engine

Specifications

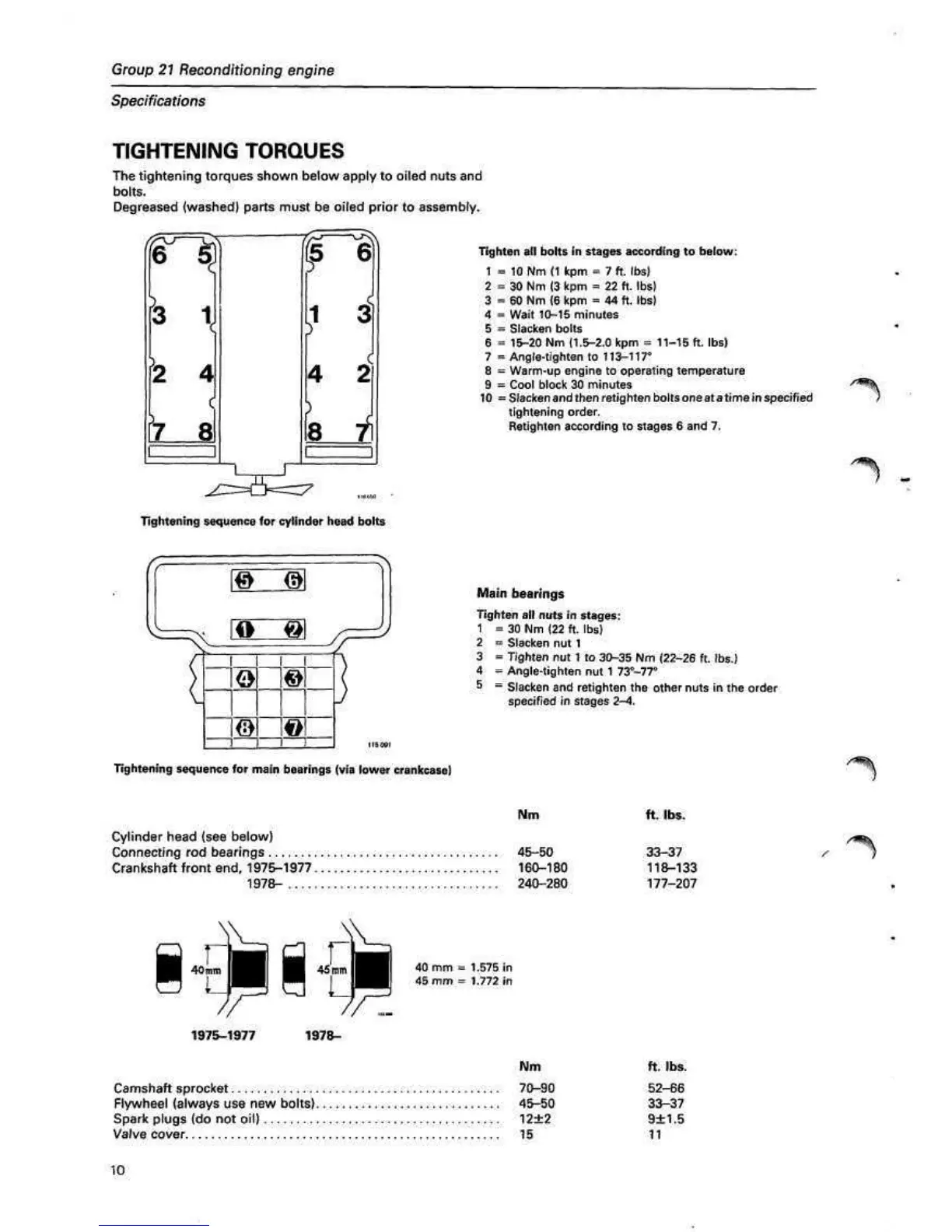

TIGHTENING TORQUES

The tightening torques shown below apply to oiled nuts and

bolts.

Degreased (washed) parts must be oiled prior to assembly.

Tighten all bolts in stages according to below:

1 = 10

Nm

(1

kpm =

7 ft. lbs)

2 = 30

Nm

(3 kpm

=

22 ft. lbs)

3 = 60 Nm

(6

kpm - 44 ft. lbs)

4 = Wait

10-15

minutes

5 = Slacken bolts

6 =

15-20

Nm

(1.5-2.0

kpm =

11-15

ft. lbs)

7 = Angle-tighten to

113-117°

8 = Warm-up engine to operating temperature

9 = Cool block 30 minutes

10 = Slacken

and

then retighten

bolts one at a

time

in

specified

tightening order.

Retighten according to stages 6 and 7.

Tightening sequence for cylinder head bolts

#

®

o

a

!

©

©

i i

®

»

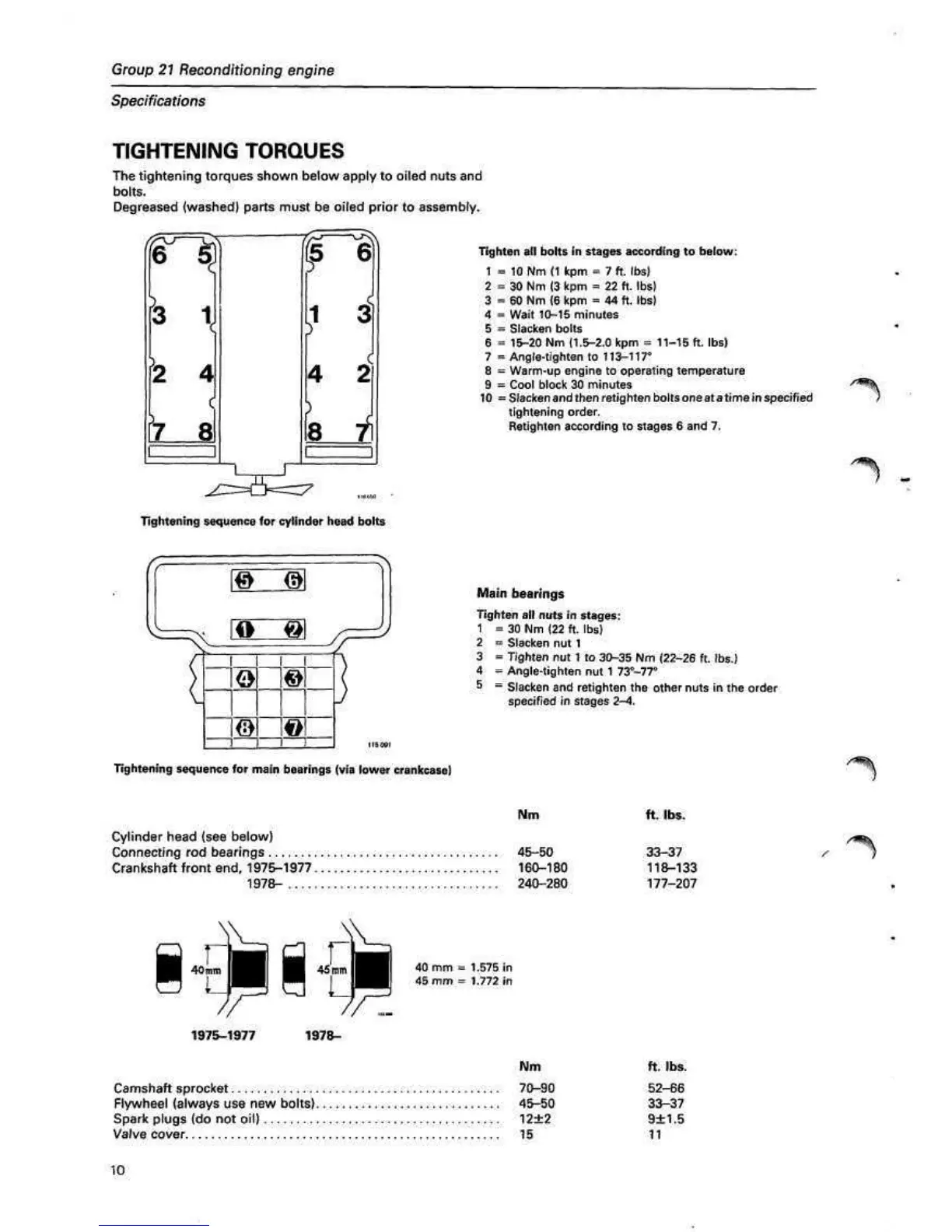

Tightening sequence for main bearings (via lower crankcase)

Main bearings

Tighten all nuts in stages:

1 = 30 Nm (22 ft. lbs)

= Slacken nut 1

= Tighten nut 1 to

30-35

Nm (22-26 ft. lbs.)

= Angle-tighten nut 1 73°-77°

=

Slacken and retighten the other nuts in the order

specified in stages 2-4.

Nm

Cylinder head (see below)

Connecting rod bearings 45-50

Crankshaft front end,

1975-1977 160-180

1978-

240-280

ft.

lbs.

33-37

118-133

177-207

40 mm = 1.575 in

45 mm

=

1.772 in

1975-1977

1978-

Nm

Camshaft sprocket 70-90

Flywheel (always use new bolts) 45-50

Spark plugs (do not oil)

12±2

Valve cover

15

ft.

lbs.

52-66

33-37

9±1.5

11

10

Loading...

Loading...