Group 27 Reconditioning engine

Thread repairs

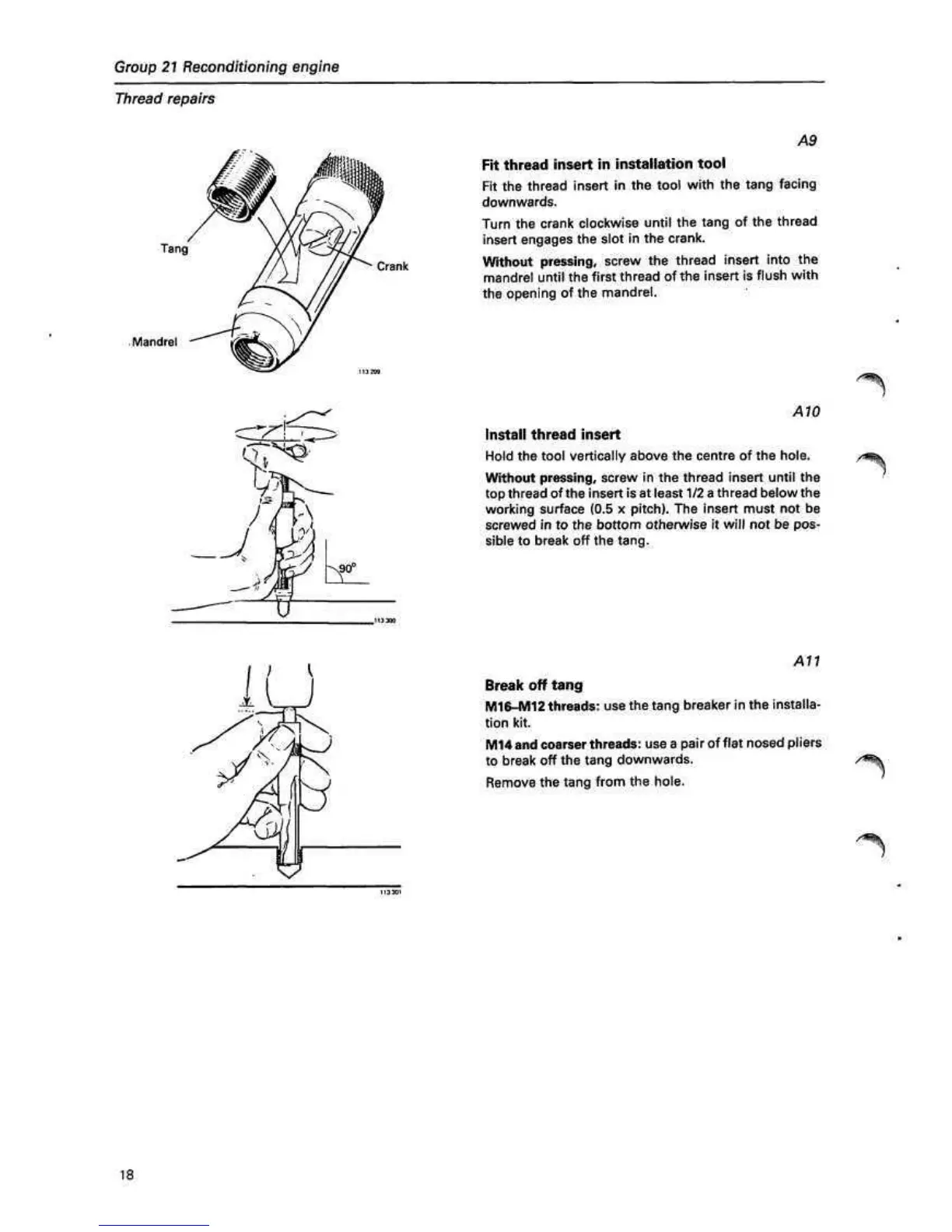

Tang

Mandrel

Crank

A9

Fit thread insert in installation tool

Fit the thread insert in the tool with the tang facing

downwards.

Turn the crank clockwise until the tang of the thread

insert engages the slot in the crank.

Without pressing, screw the thread insert into the

mandrel until the first thread of the insert is flush with

the opening of the mandrel.

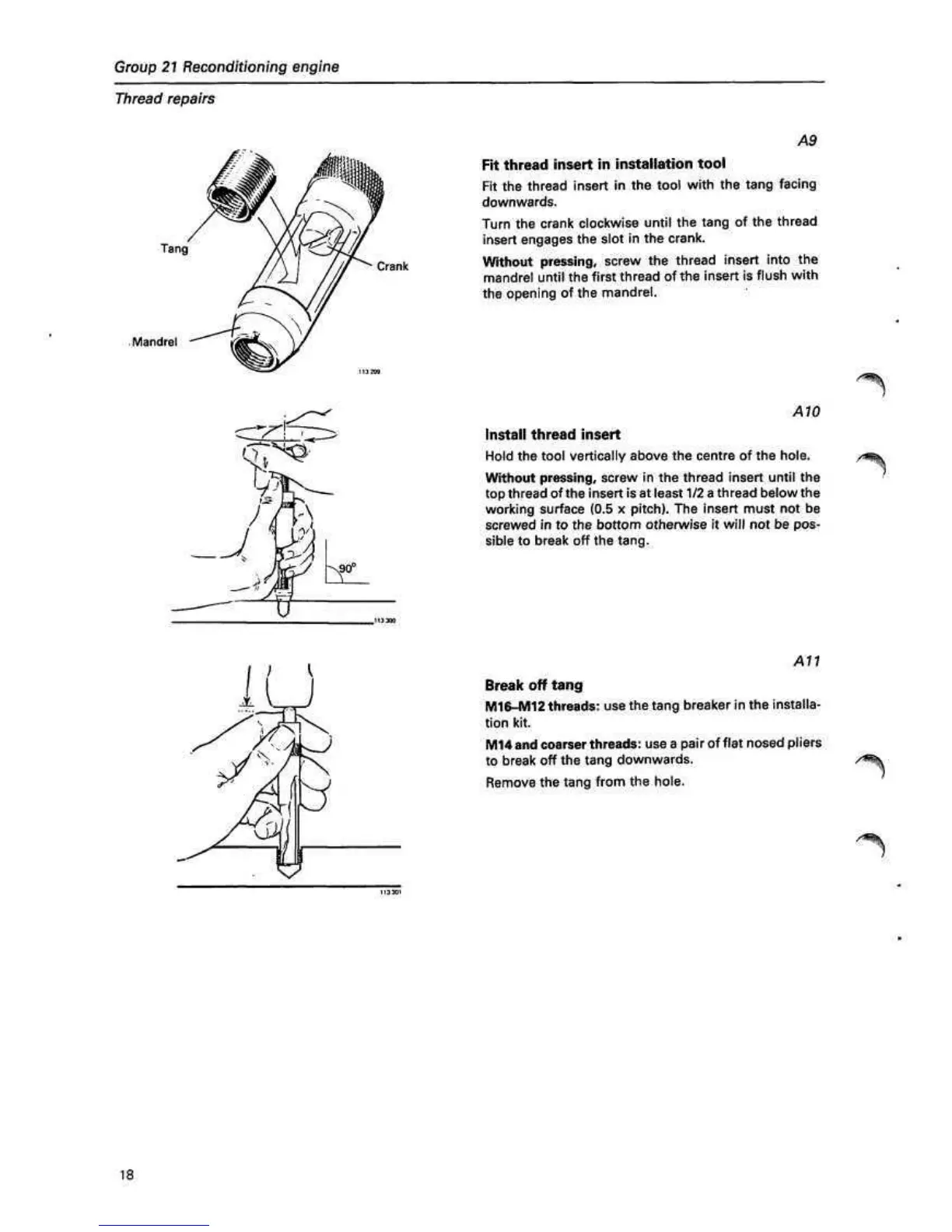

AW

Install thread insert

Hold the tool vertically above the centre of the hole.

Without pressing, screw in the thread insert until the

top thread of the insert is at least 1/2

a

thread below the

working surface (0.5 x pitch). The insert must not be

screwed in to the bottom otherwise it will not be pos-

sible to break off the tang.

AH

Break off tang

M16-M12

threads:

use the tang breaker in the installa-

tion kit.

M14 and

coarser

threads:

use a pair of

flat nosed pliers

to break off the tang downwards.

Remove the tang from the hole.

18

Loading...

Loading...