Group

21

Reconditioning engine

Assembly

D5

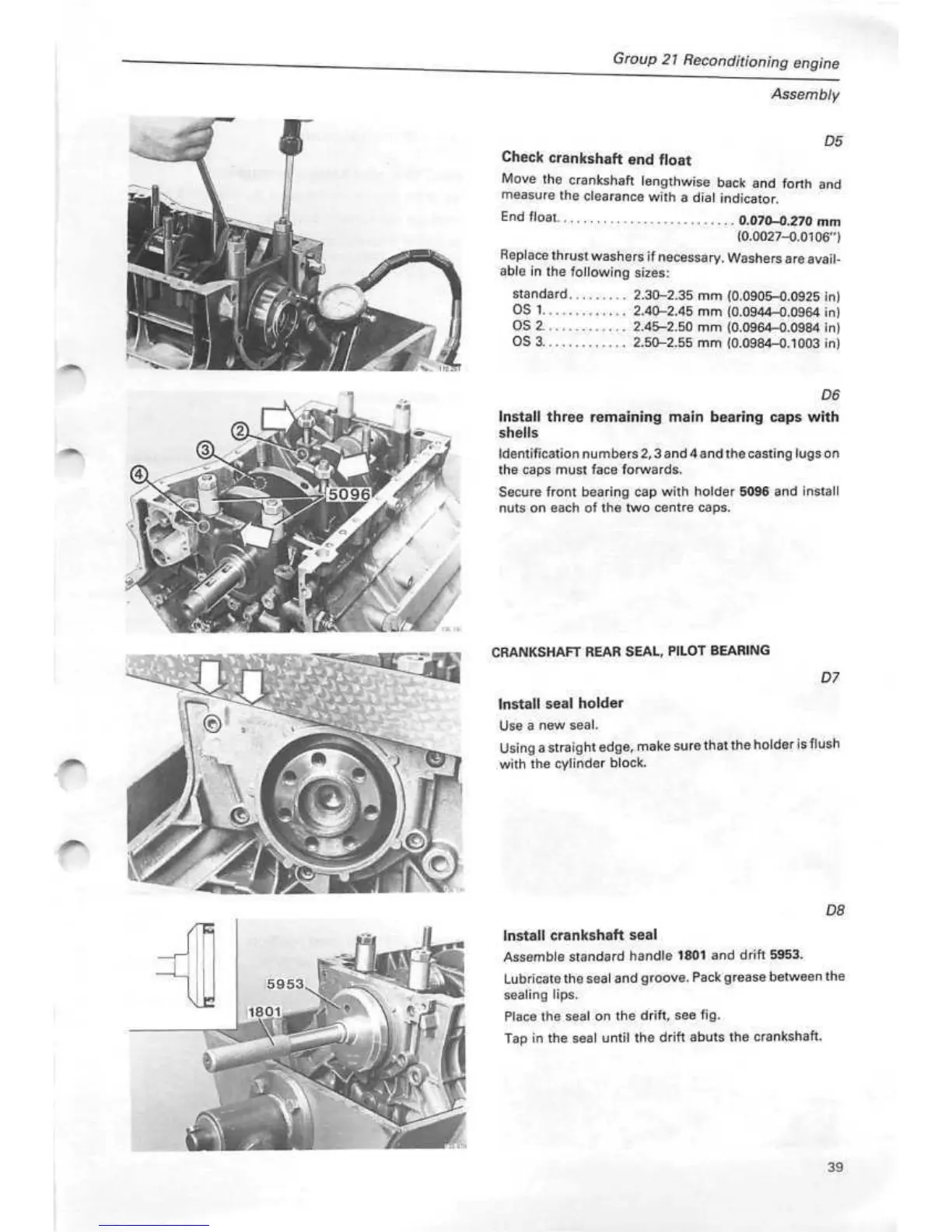

Check crankshaft end float

Move the crankshaft lengthwise back and forth and

measure the clearance with a dial indicator.

End float

0.070-0.270

mm

(0.0027-0.0106")

Replace thrust washers if necessary. Washers are avail-

able in the following sizes:

standard

2.30-2.35

mm

(0.0905-0.0925

in)

OS 1

2.40-2.45

mm (0.0944-0.0964 in)

OS 2 2.45-2.50 mm (0.0964-0.0984 in)

OS 3

2.50-2.55

mm

(0.0984-0.1003

in)

D6

Install three remaining main bearing caps with

shells

Identification

numbers2,3and4andthecasting

lugson

the caps must face forwards.

Secure front bearing cap with holder 5096 and install

nuts on each of the two centre caps.

CRANKSHAFT REAR SEAL, PILOT BEARING

D7

Install seal holder

Use a new

seal.

Using a straight edge, make sure that the holder is flush

with the cylinder block.

D8

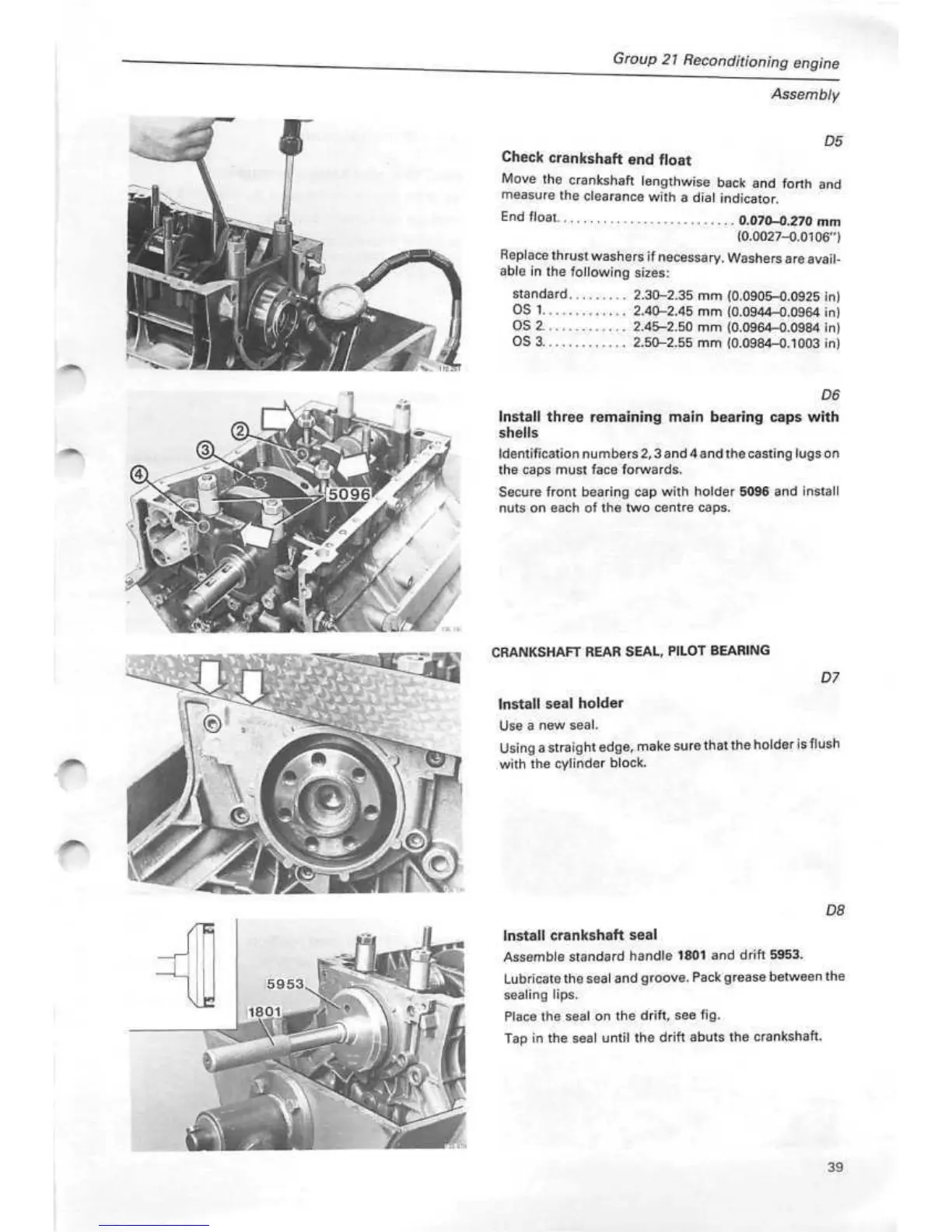

Install crankshaft seal

Assemble standard handle 1801 and drift 5953.

Lubricate the seal and groove. Pack grease between the

sealing lips.

Place the seal on the drift, see fig.

Tap in the seal until the drift abuts the crankshaft.

39

Loading...

Loading...