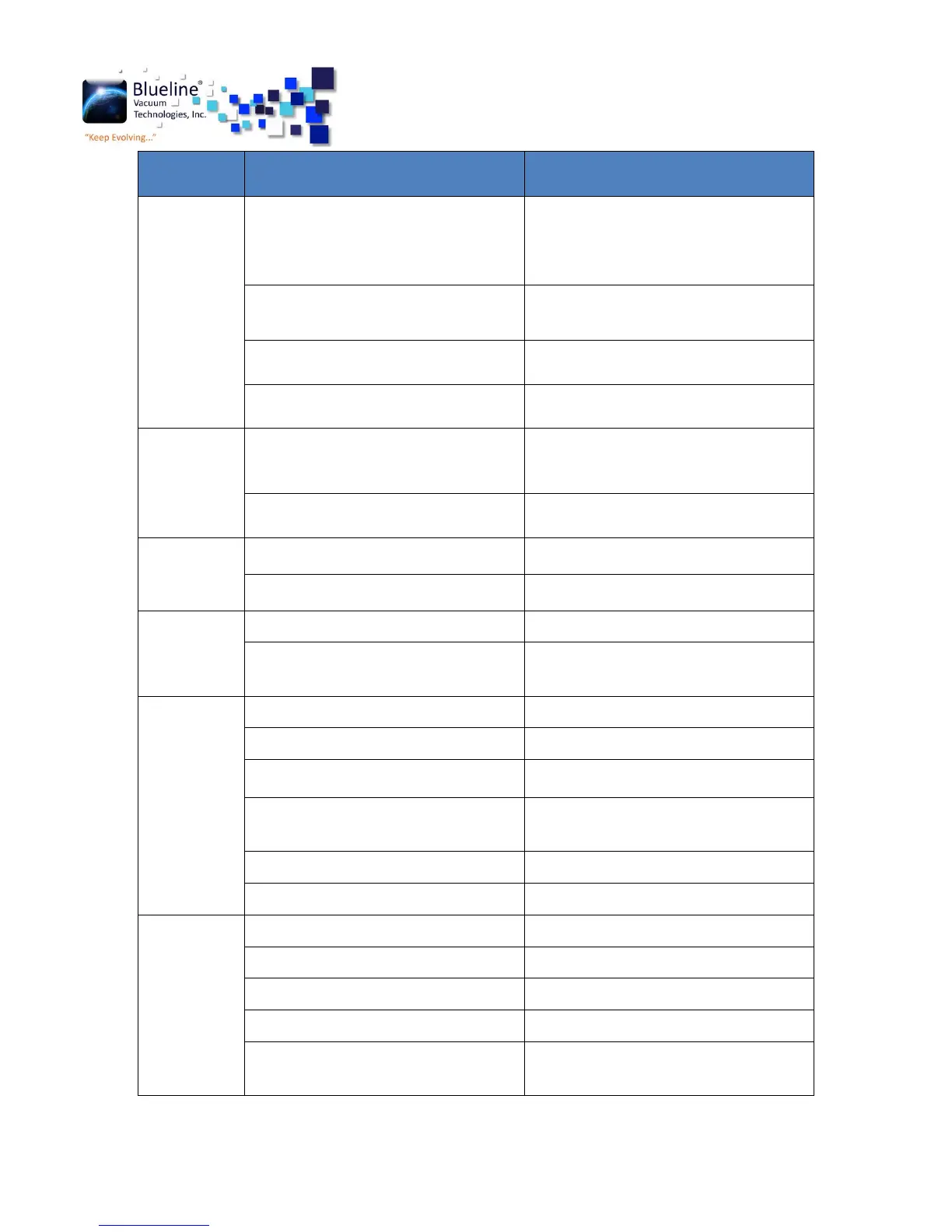

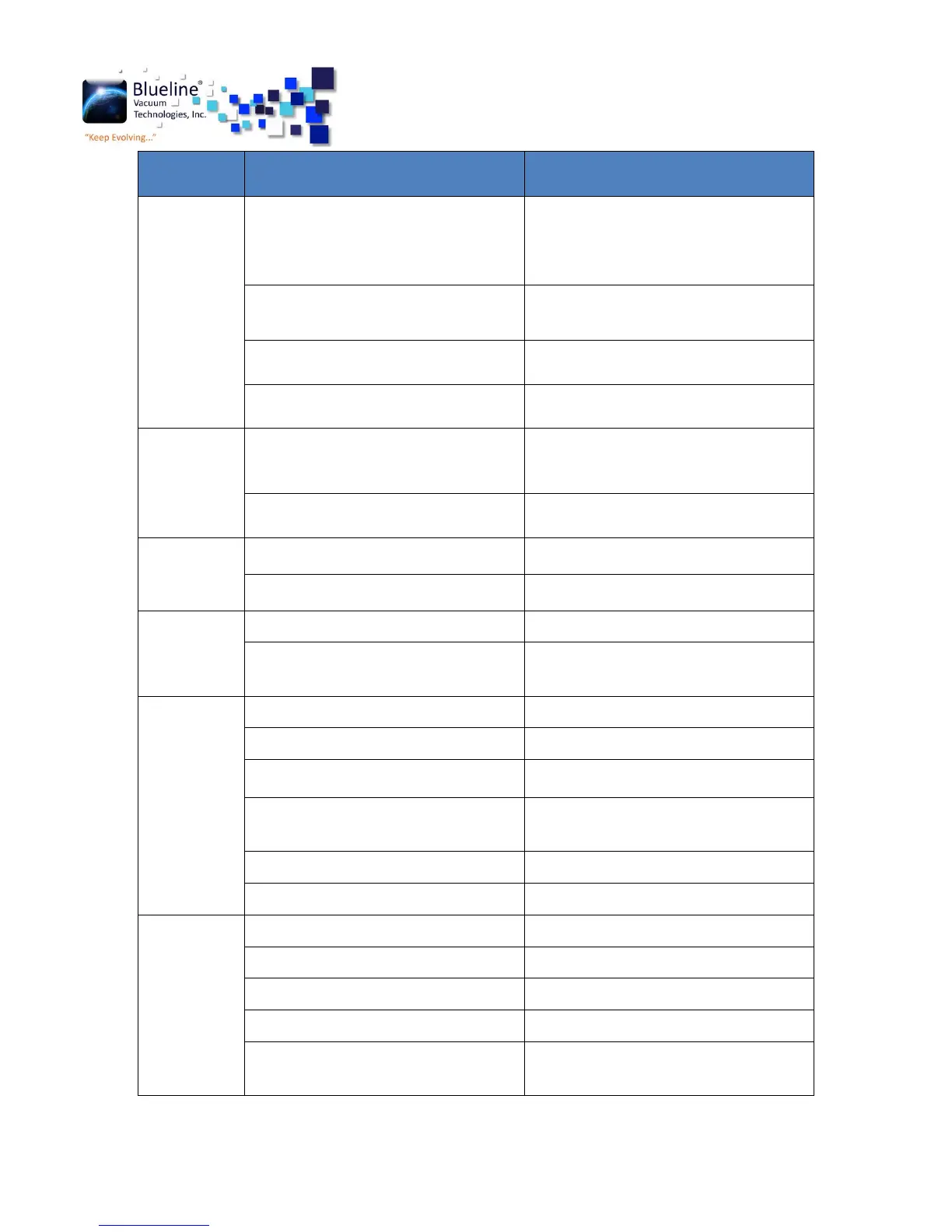

16

www.bluelinevacuum.com

Clearance between casing and impellers

is too small due to:

-contamination

-distortion of pump.

Clean the pumping chamber.

Ensure that the feet and connecting lines

aren’t placing a strain on the pump.

Bearing or gearing is damaged.

After sales service. Switch off the pump at

once.

Impellers strike the casing.

After sales service. Switch off the pump at

once.

After sales service. Switch off the pump at

once.

Oil leak is visible:

Oil drain plug is not tight.

Drain lubricant, firmly screw in the oil drain

plug with a new gasket, and fill in the

correct quantity.

No oil leak is visible;

See fault “oil in the pumping chamber”

See fault “oil in the pumping chamber”

Oil level in the

oiler drops

Oil leak is visible:

Outer shaft seal is malfunctioning.

No oil leak is visible;

Inner shaft seal is malfunctioning.

See fault “pump gets too hot”. After solving

the problem change the oil.

Oil in the

pumping

chamber

.

Drain lubricant to reach the correct oil level.

Oil leaks out of the system.

Pump is not installed on a flat horizontal

surface.

Pump has an external leak.

Check proper fit of oil-fill and oil-drain

plugs, replace gaskets if necessary.

Pump has an internal leak.

Impeller rings are malfunctioning.

Pumping

speed of

the pump is

too low

Motor is connected incorrectly.

Connect the motor correctly.

Pump or pump system has a leak.

Overflow valve does not close.

Clean or repair the valve.

Flow resistance in the intake or discharge

line is too high.

Use intake and discharge lines of sufficient

diameter.

Loading...

Loading...