15

www.bluelinevacuum.com

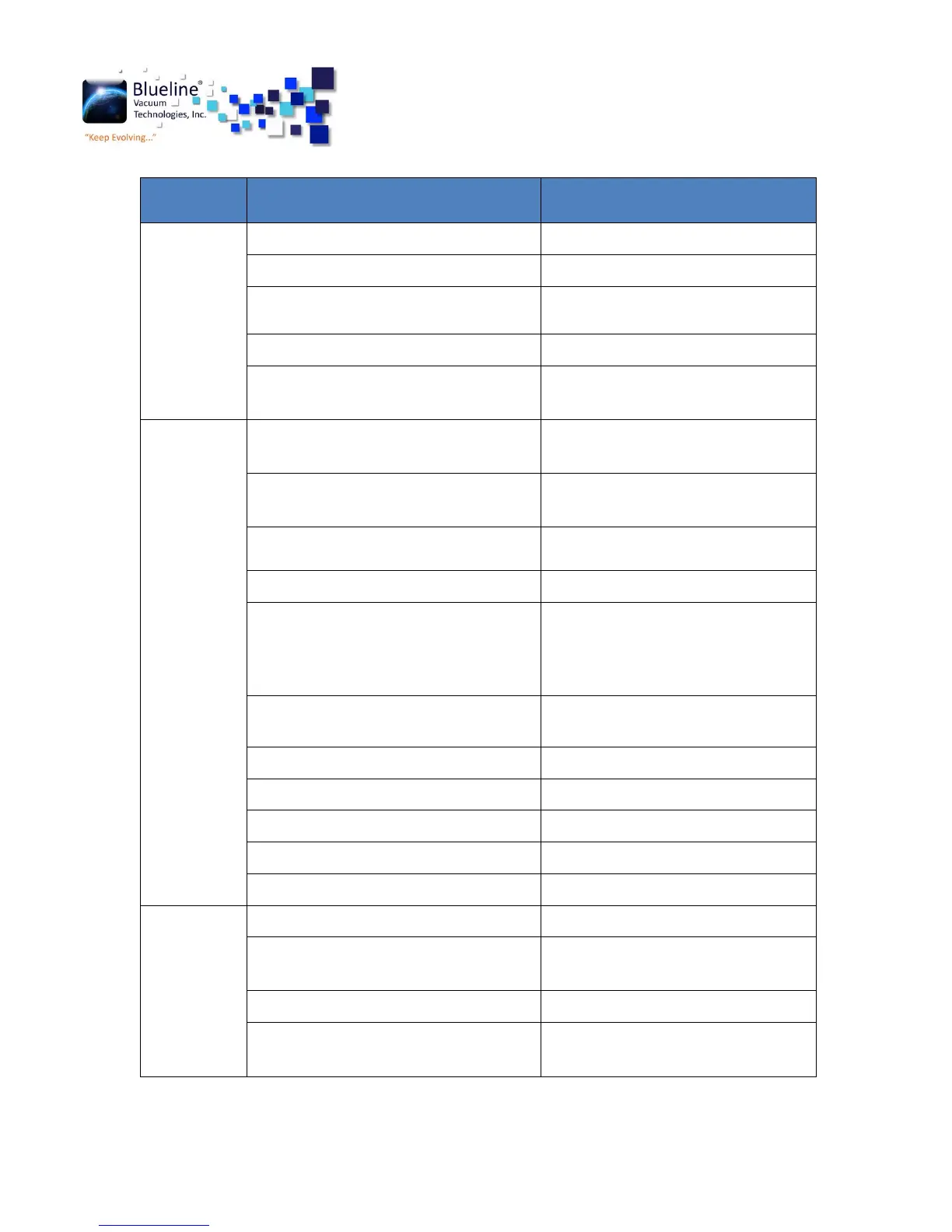

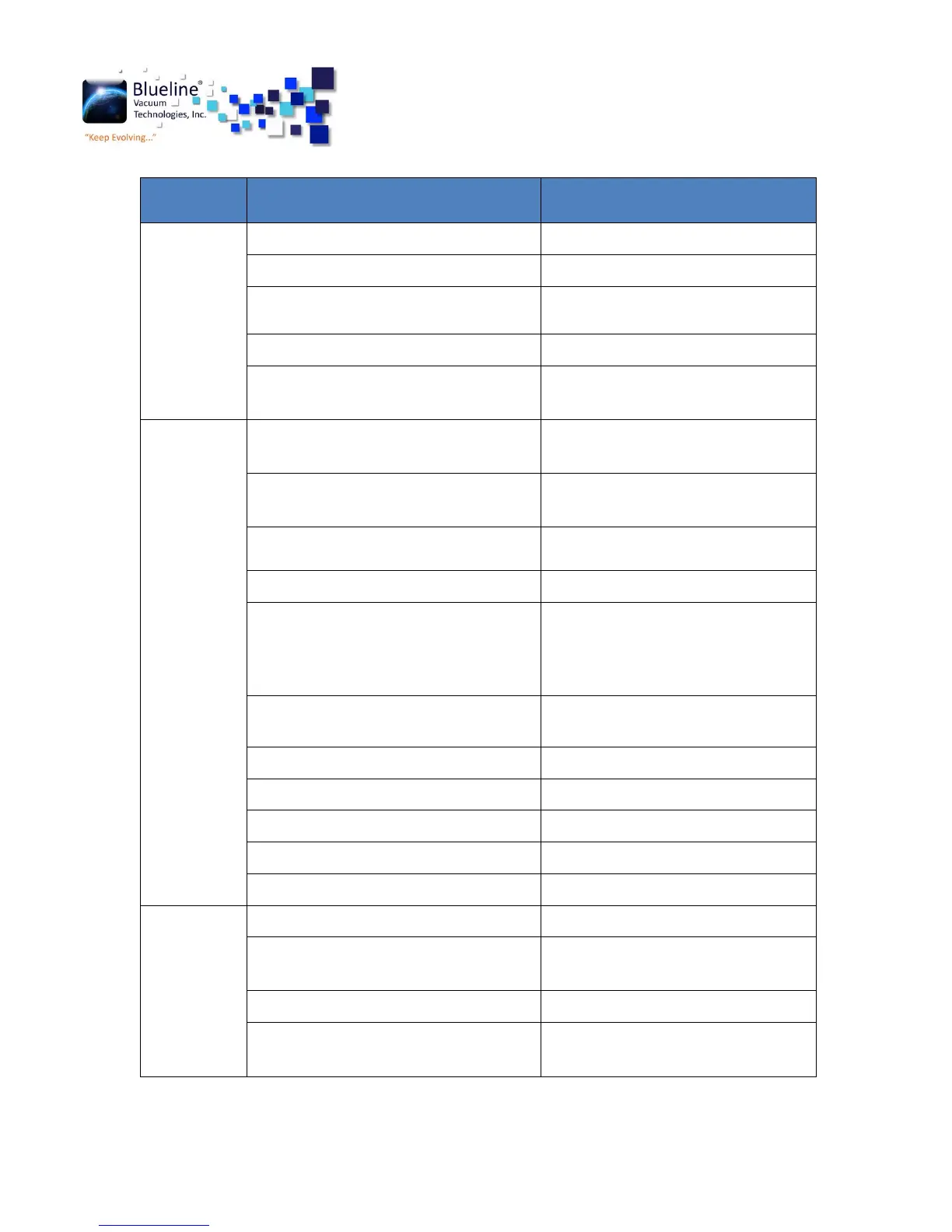

7.8 Troubleshooting

Motor is connected incorrectly.

Connect the motor correctly.

Replace the pressure switch.

Change the oil or warm the oil and the

pump.

Motor rotor is malfunctioning.

Pump has seized up: damaged impellers,

bearings or gearwheels.

Ambient temperature is too high or cooling

water supply is obstructed.

Install the pump at a suitable site or

ensure enough cooling water.

Pump is working in the wrong pressure

range.

Check pressure values of vacuum

system.

Pressure differential is too great.

Check pressure values of vacuum

system.

Gas temperature is too high.

Clearance between casing and impellers is

too small due to:

-

contamination

-

Distortion of pump.

Clean the pumping chamber.

Ensure that the feet and connecting

lines aren’t placing a strain on the pump.

Excessive frictional resistance due to

contaminated bearings and/or oil.

Drain some oil to reach the correct level.

Add oil to reach the correct level.

Drain oil and fill in correct lubricant.

Bearing are malfunctioning.

Overflow valve does not open.

Clean or repair the valve.

Power

consumption

of the motor

is too high.

See fault “pump gets too hot”.

See fault “pump gets too hot”.

Wrong mains voltage supply for the motor.

Connect the motor to the correct

voltage supply.

Repair the motor or exchange it.

Exchange the oil or warm up the oil and

the pump.

Loading...

Loading...