tection and pretension o-ring

while being pressed into the

coupling element, until both

clips snap into place in the

groove of the plug.

The first clip snaps into place

when only very little force is

applied. In this initial retention

position, the connection is

already secured against unin-

tentional loosening, but it is

not yet leak-tight. The con-

nection ist not fully sealed until

the second clip snaps into

Thread sizes Nominal size Across flats Tightening

torque

NS Nm

M 16 x 1.5 8 19 10 - 17

M 22 x 1.5 12 24 10 - 17

Coupling element:

1 Male nut Brass

2 Thread-sealing o-ring NBR 70

3 Fixing ring POM

4 Retaining element Spring steel/POM

4.3 Assembly of the

coupling element

In order to achieve safe func-

tioning, the connecting port

should be cleaned before fit-

ting the coupling element.

In particular, any residue of

paint still attached to the

region of the sealing lip should

be removed. Care is also be

taken to ensure that the

thread of the component is at

right angles to the contact

surface of the coupling ele-

ment.

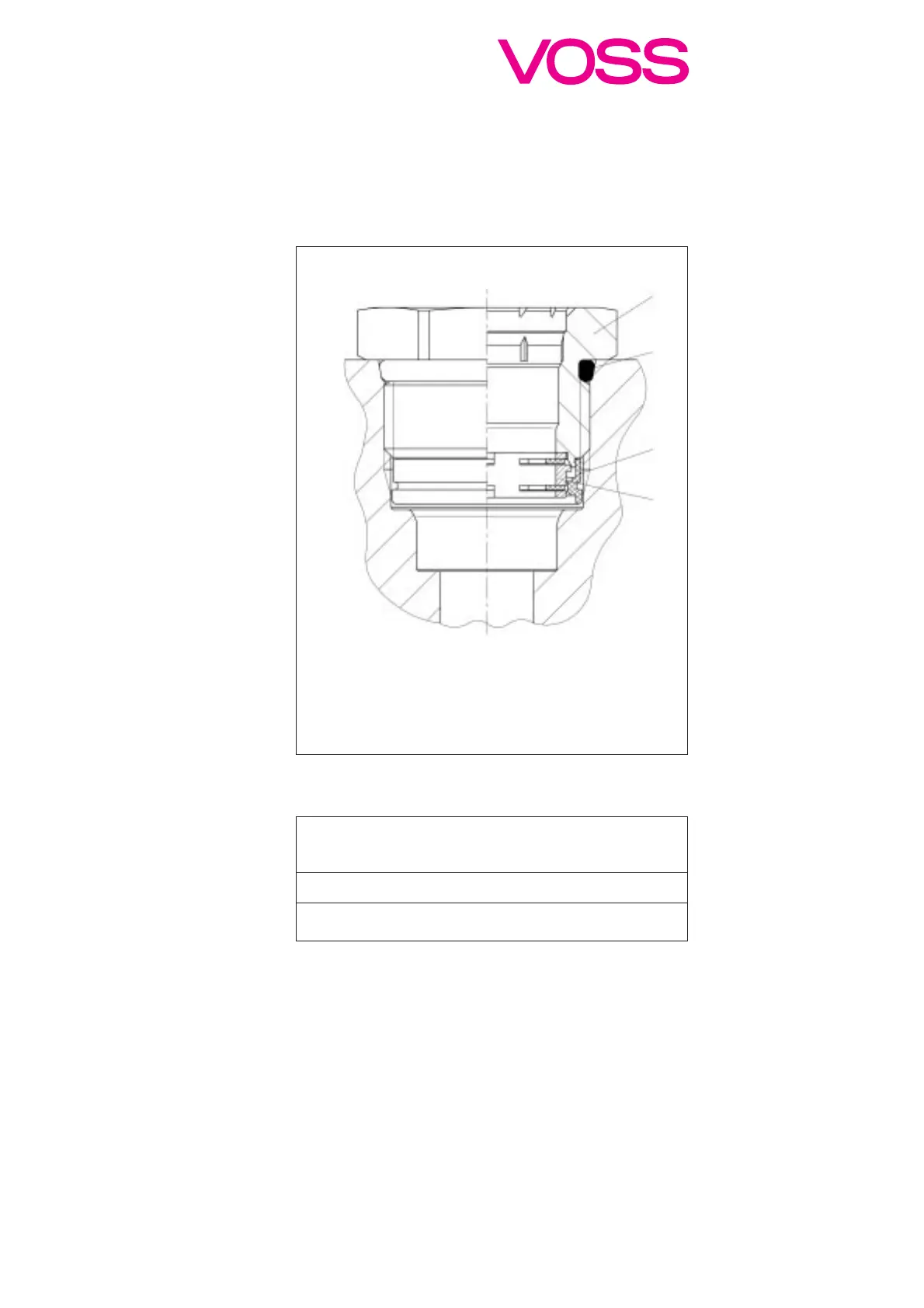

The coupling element consists

of a male nut (1) with greased

thread-sealing o-ring (2) and

retaining element (4) clipped

into place with a fixing ring (3).

It is available from the factory

with or without paint protec-

tion stickers. If there is a paint

protection sticker on the front

of the coupling unit, it should

not be removed. The coupling

unit is screwed hand-tight

into the connecting port.

When the coupling element is

inserted into the thread, the

fixing ring acts to pre-align

the coupling element, thus

facilitating the assembly.

Now the coupling element

should be tightened with a

torque wrench. For this pur-

pose, the flap of the paint

protection sticker should be

folded upward. The recom-

mended tightening torques

are listed in table on the right.

The values quoted are valid

both for metal (die-cast alumi-

nium, die-cast zinc) and for

nylon casings (PA-GF30) with

VOSS V-thread.

Automatic VOSS assembly

tools are available on request

for high volume assembly.

7

4.4 Connecting line to

component

Now the protective cap can

be removed from the plug

(see section 4.2.3) and the

paint protection sticker can be

removed from the coupling

element (see section 4.3).

Slide plug with nylon tube fit-

ted to fir-tree into the port of

the coupling element. The

plug must overcome the axial

force exerted by the dirt-pro-

place. To conclude the inser-

for insertion. Always ensure

sit at a false angle in the port.

correctly fitted.

ring is not visible.

Incorrect connections, i.e.

bar). This will not result in

damage. Whether

installation location.

Loading...

Loading...