CAUTION!

Connections which have not snapped into place

can impair braking performance and may even

lead to failure of the entire pneumatic system.

8

4.5 Disconnecting and

reassembling

The pneumatic line connected

must be free of any pressure

before it is detached. If the

plug is detached while the line

is pressurised, it can cause

personal injury and damage to

connecting components or to

the pneumatic unit. These

damaged components must

then be replaced. All individual

components must be cleaned

before reassembly.

In order to replace compo-

nents, loosen the male nut

and remove the connection.

The nylon tube with plug and

coupling element with o-ring

need not to be separated.

Check the port on the new

unit is clean. Then re-grease

the thread-sealing o-ring,

screw in coupling element

with plug, fitted with nylon

tube and tighten male nut.

(For tightening torque, see

section 4.3).

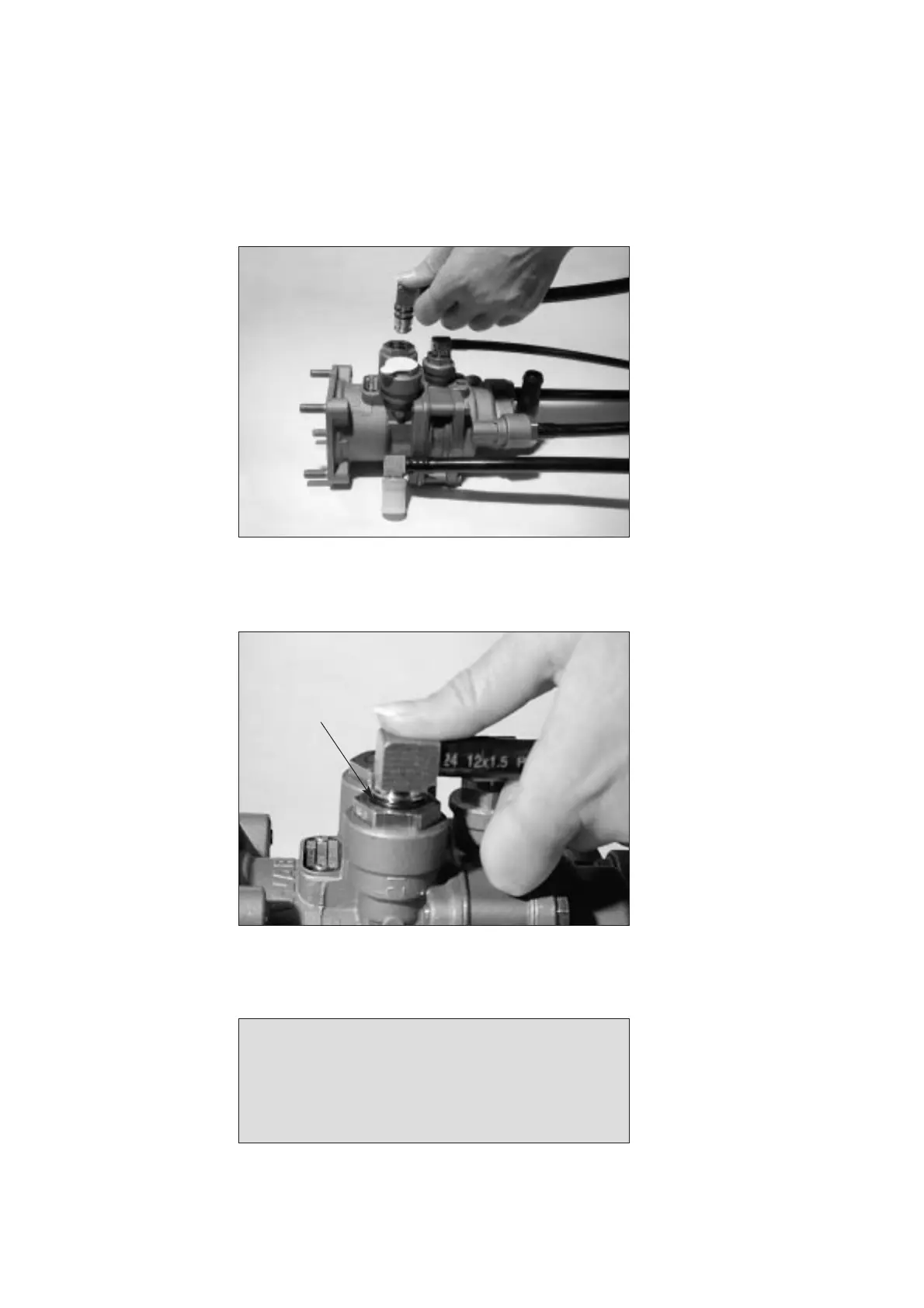

Final assembly:

Inserting plug and subsequently pulling back to check

correct fitting

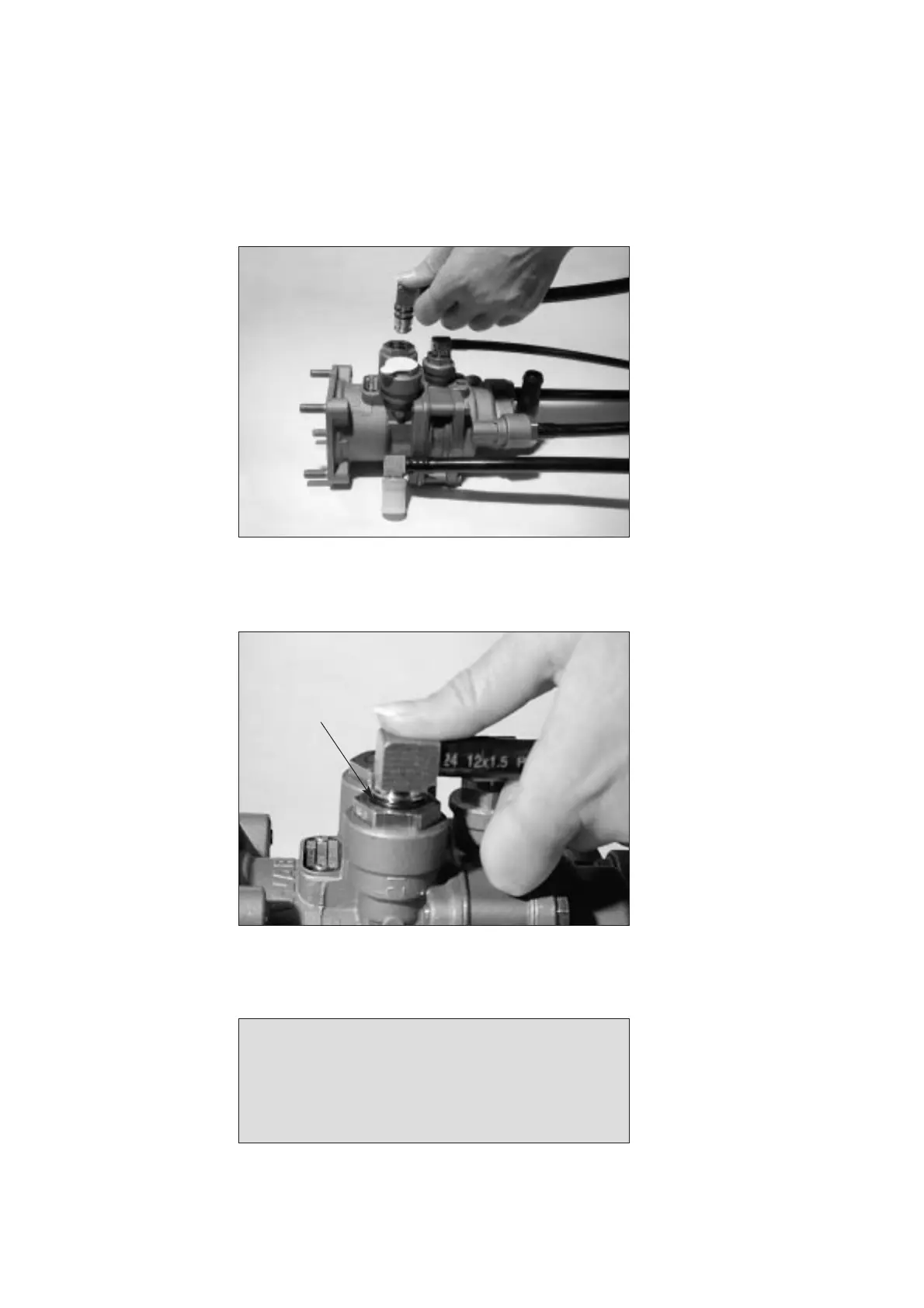

Final assembly:

Incomplete connection at first snap-in stage; the dirt-protection

and pretension o-ring is visible after pulling back the plug.

Loading...

Loading...