BS 60-2 / BS 70-2 Maintenance

wc_tx000926gb.fm 33

5.4.4 Remove the sightglass. Clean the threads of the sightglass, then

wrap the threads with Teflon tape.

5.4.5 Add oil to the machine through the sightglass opening in the housing.

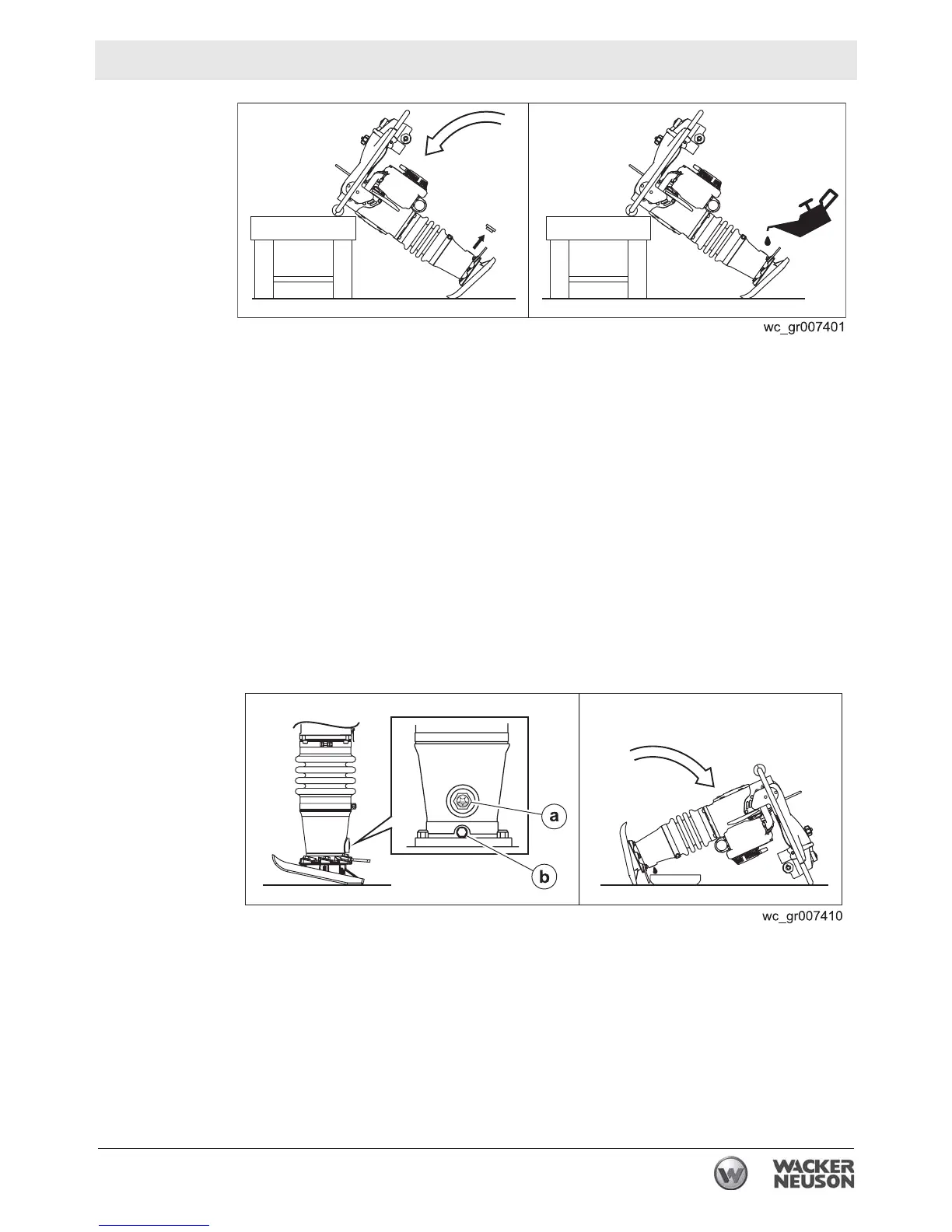

5.4.6 Stand the machine upright to check the oil level. Add enough oil so

that when the machine is upright, oil will fill 1/2 to 3/4 of the sightglass.

At that point, install the sightglass. Torque the sightglass to 9 Nm (6

ft.lbs.).

Changing oil

Perform the following procedure to change the ramming system oil.

Note: Dispose of used oil in accordance with local environmental regula-

tions.

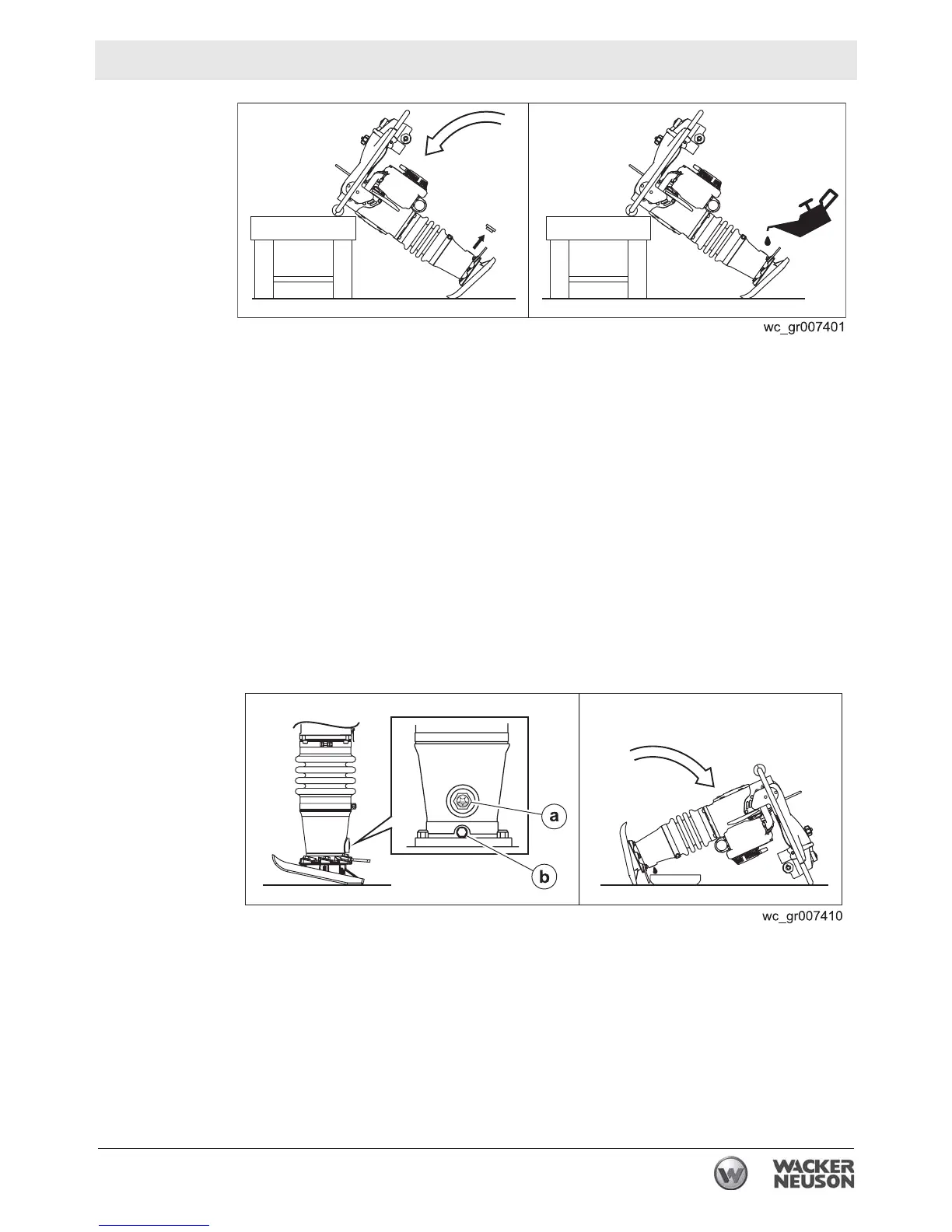

5.4.7 Remove the drain plug (b). (On BS 50 machines, remove the

sightglass (a).)

5.4.8 Tilt the rammer backward until it is resting on the handle and drain the

oil into a suitable container.

Note: It may take up to 10 minutes for the oil to drain.

5.4.9 Reinstall the drain plug. Torque it to 54 Nm (40 ft.lbs.).

5.4.10 Add oil as stated above.

Loading...

Loading...