10 Maintenance

30 100_0201_mt_0005.fm

10.If need be, top up with oil until the oil sight glass is 1/2 to 3/4 full.

11.Now tighten the oil sight glass. Tightening torque 9 Nm.

12.Wipe the area around the oil sight glass with a clean cloth.

10.2.6 Oil change

1. Remove dirt around the oil sight glass.

2. Unscrew the oil sight glass. Clean the thread on the oil sight glass and wrap with Teflon tape.

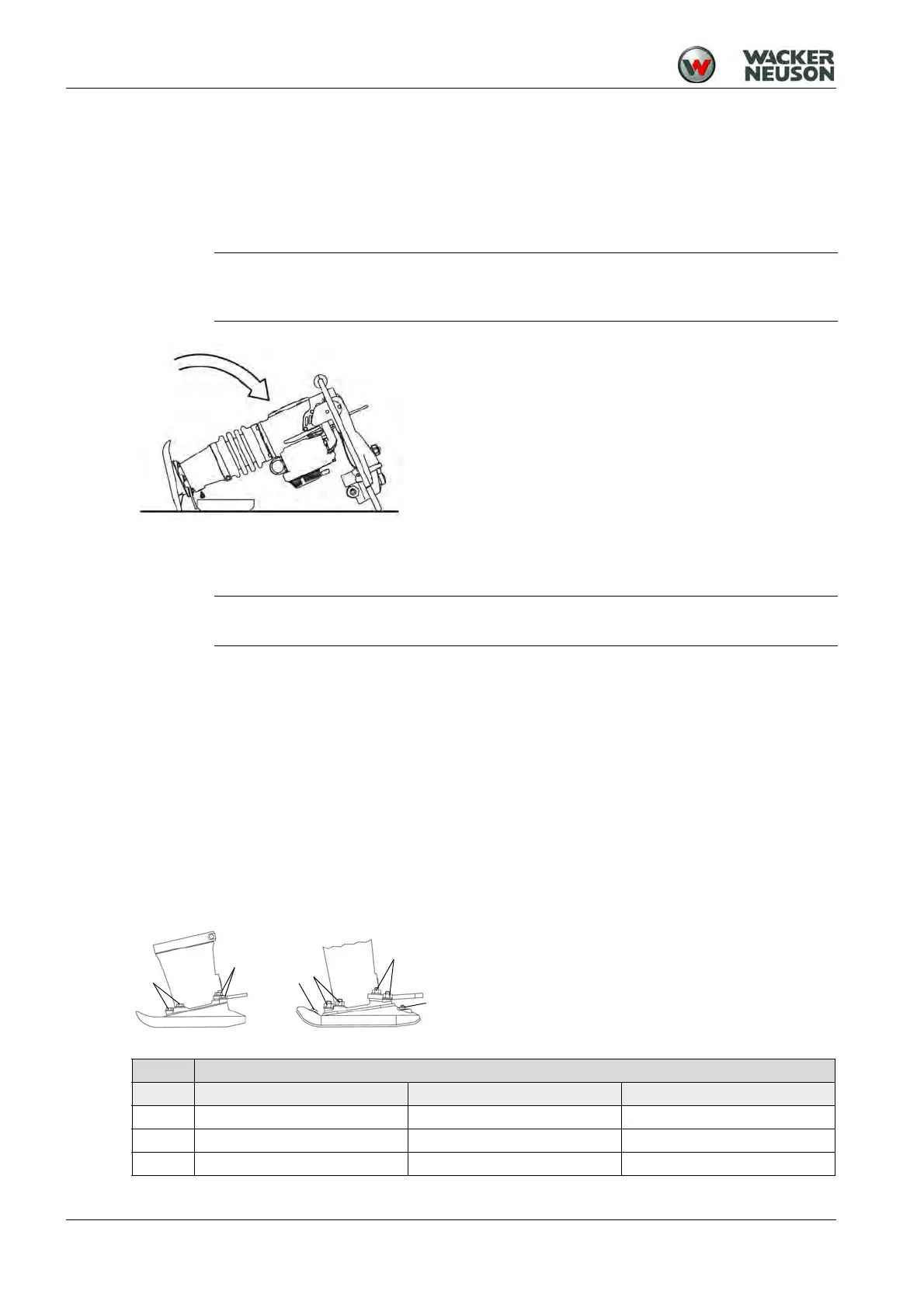

3. Tilt the vibrating rammer backwards until it comes into contact with the guide clip and drain the waste

oil into a suitable container.

4. Tilt the vibrating rammer forward and secure it in this position.

5. Fill the housing with oil through the opening in the oil sight glass. For oil specification, see section

Technical Data.

6. Screw the oil sight glass on again, but do not tighten.

7. Place the vibrating rammer in an upright position to check the oil level.

8. If need be, top up with oil until the oil sight glass is 1/2 to 3/4 full.

9. Now tighten the oil sight glass; tightening torque 9 Nm.

10.Wipe the area around the oil sight glass with a clean cloth.

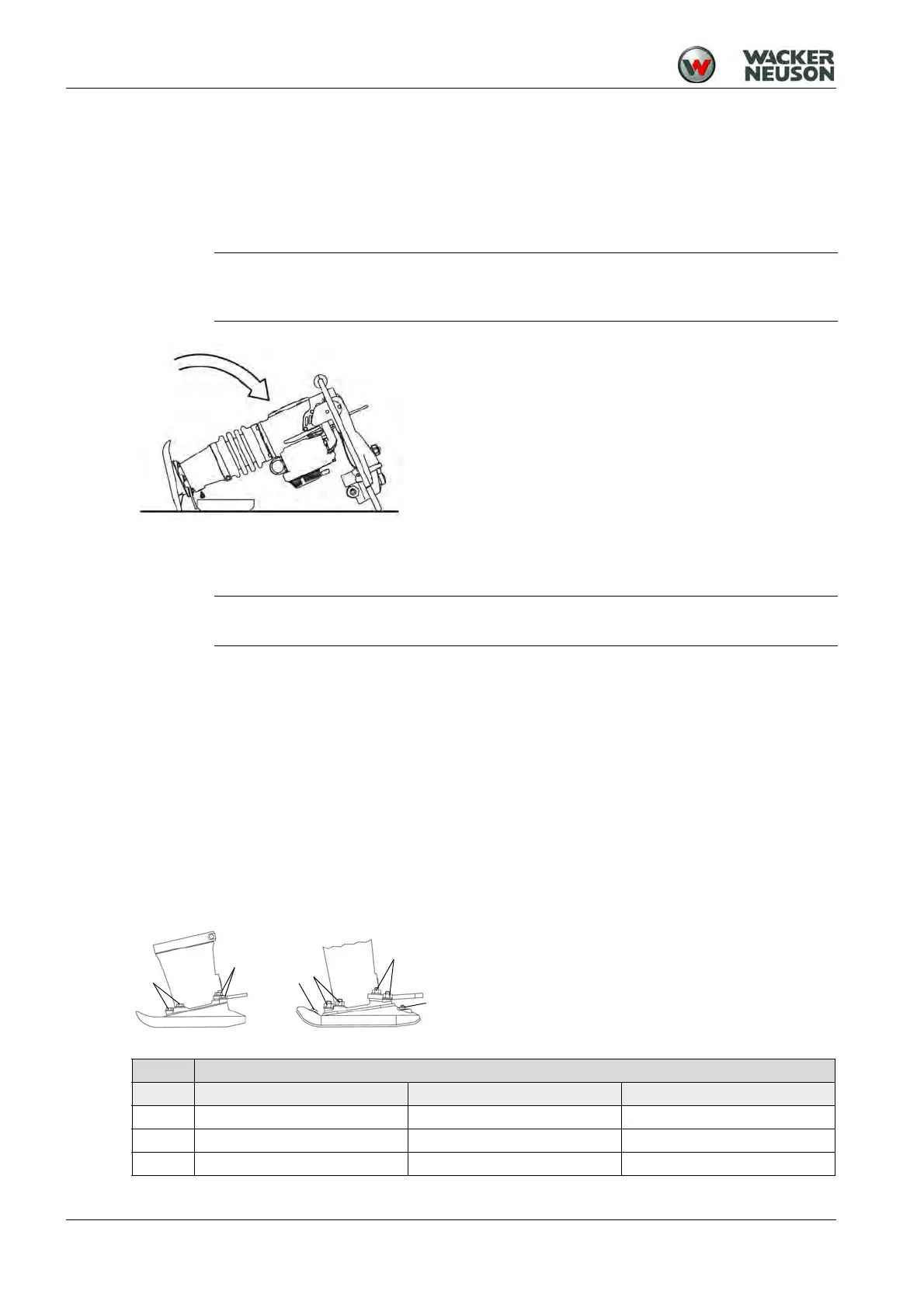

10.2.7 Check/retighten screw joints on the rammer base.

All screw joints on the rammer base in vibrating rammers must be checked at regular intervals for firm

seating.

NOTE

Waste oil must be disposed of in accordance with the applicable local environmental

protection regulations.

NOTE

This can take up to 10 minutes.

Item Tightening torque in Nm (ft-lbs.)

6" 11" 13"

186 (63)

2 19 (14) 18 (13)

3 79 (58) 85 (63)

Loading...

Loading...