wc_tx003863gb_FM10.fm

51

RT / RTx Operation

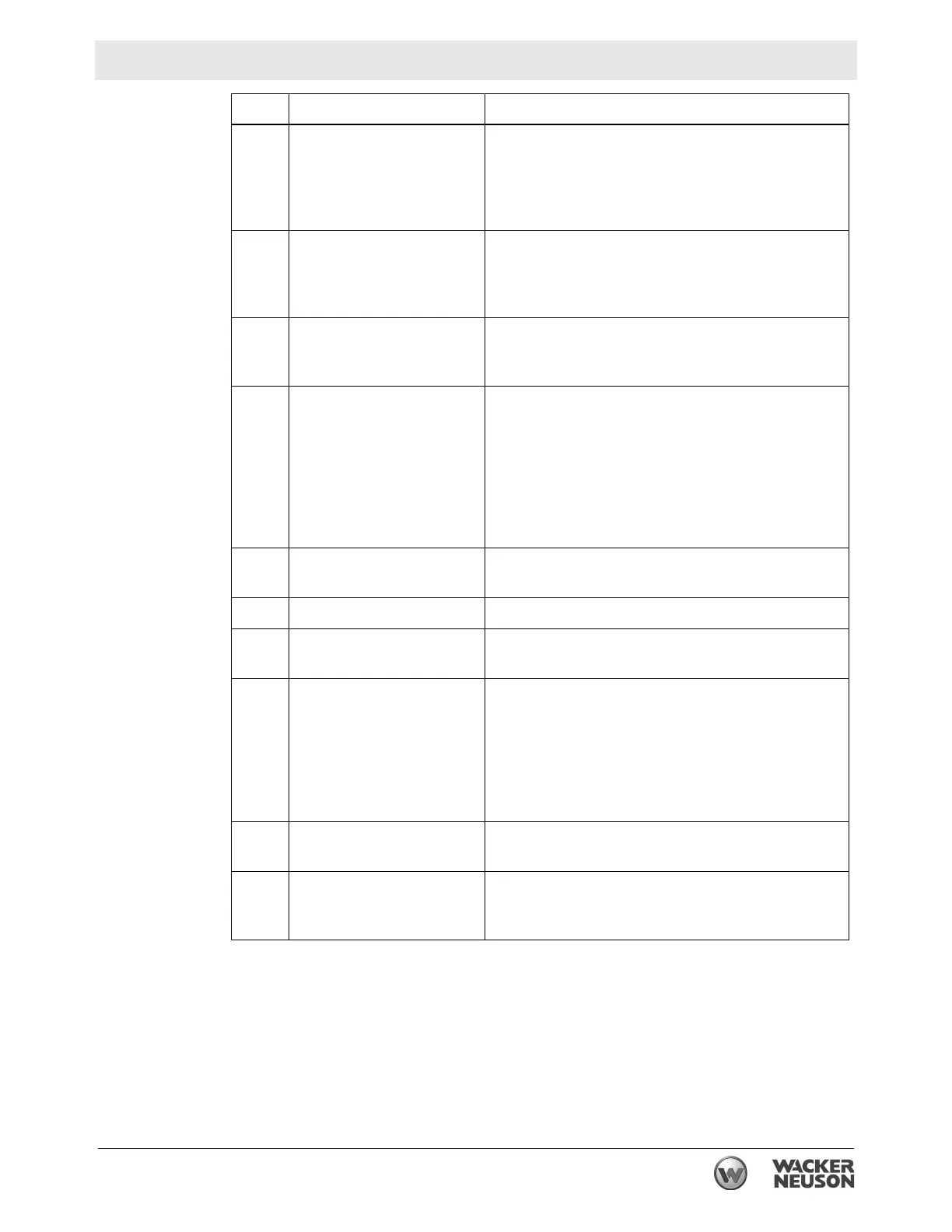

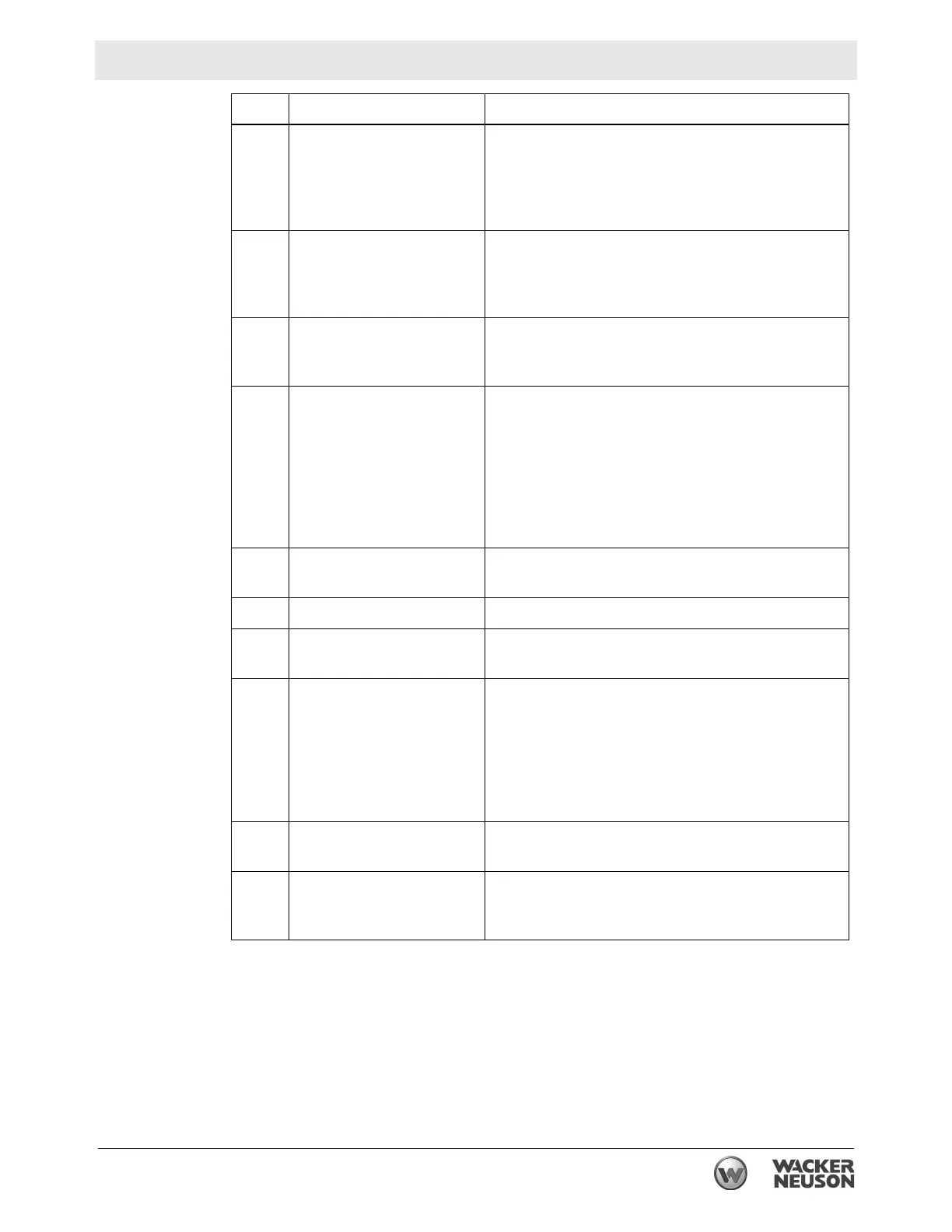

e Near field transmitting

diodes (LEDs)

These LEDs—located on all sides of the

transmitter—are part of the machine’s sensing

system which stops the machine when the

operator and transmitter are located too close to

the machine.

f Operating status indicator This LED indicates the operating status of the

transmitter.

See Operating Status Indicator Codes.

h Engine START

pushbutton

Pressing this button causes the engine to crank.

An override prevents the engine from cranking if it

is already running.

j ON/OFF pushbutton Pressing this button turns on and off the

SmartControl™ transmitter. The operating status

indicator (f) illuminates green (flashing) when the

transmitter is on.

Turning the transmitter off stops the engine and the

machine. See topic 4.25 Emergency Shutdown

Procedure.

k LOW vibration pushbutton Pressing this button causes the vibration to come

on in the LOW vibration mode.

l Vibration OFF pushbutton Pressing this button causes all vibration to stop.

m HIGH vibration

pushbutton

Pressing this button causes the vibration to come

on in the HIGH vibration mode.

— Vibration pushbuttons When the machine is moving in the high speed

travel mode, pressing either vibration pushbutton

(k or m) causes the roller to drop out of the high

speed travel mode and into the low speed travel

mode. Conversely, when the vibration is on, the

machine cannot go into the high speed travel

mode.

n Signal transmission

indicator

To aid in diagnostics, this green LED flashes any

time a signal is sent to the roller.

o Control channel selector

switch

This selector switch, when set to match that of the

machine’s decoder module, allows the

SmartControl to control the roller.

Ref Component Description

Loading...

Loading...