Maintenance Instructions LUBRICATION

60

Changing Engine Crankcase Oil/Oil Filter

Change the engine crankcase oil after every 100

hours of operation and replace the oil lter every

other oil change (every 200 hours of operation).

1. Park the mower on a level surface with the

en gine stopped. The engine oil should be

warm before draining. If not warm from opera-

tion, start the engine and run a few minutes to

warm the oil.

2. Before removing the dipstick, clean the area

around the dipstick to keep any dirt or debris out

of the engine.

3. Remove the dipstick and the oil drain plug and

drain the oil into a suitable container. Be sure

to allow ample time for complete drainage.

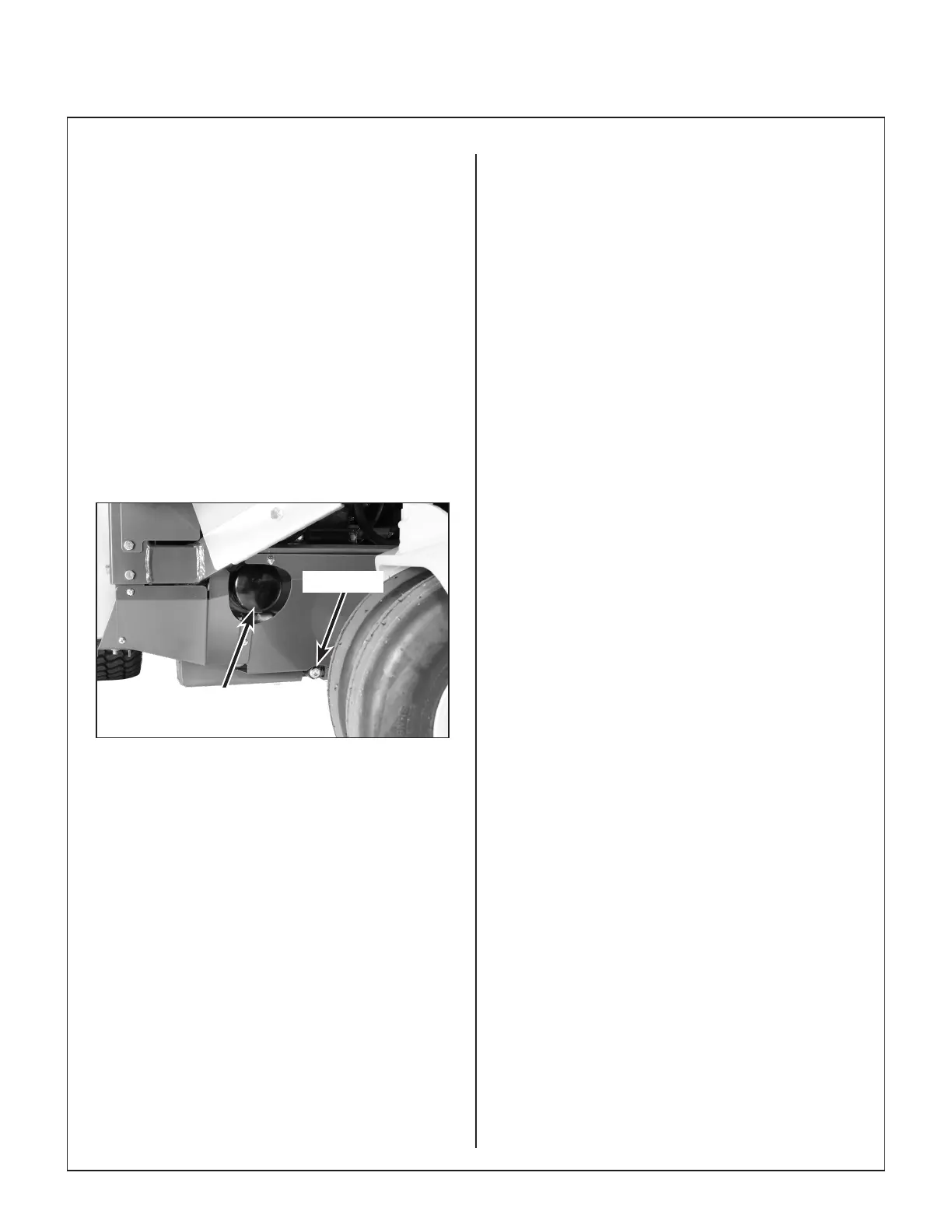

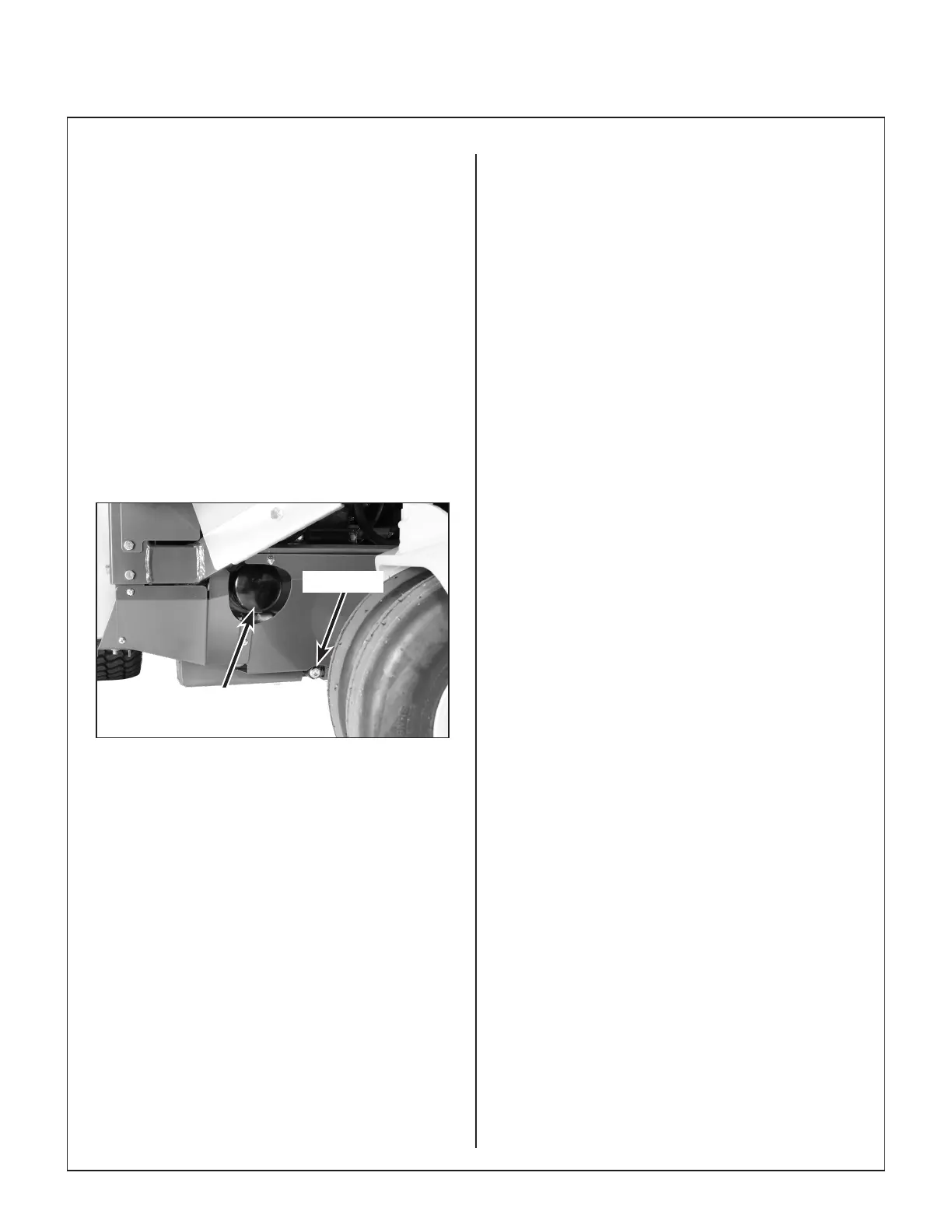

Drain Plug

Oil Filter

Oil Drain/Oil Filter Location

4. Before removing the oil lter, clean the area

around the lter to keep dirt and debris out of

the engine.

5. Remove the old oil lter and wipe off the lter

mounting surface on the engine.

6. Apply a thin coating of clean oil to the rubber

gasket on the replacement oil lter.

IMPORTANT: Use ONLY oil lters from the en-

gine manufacturer (Kohler 12-050-01). After-

market oil lters may not seal properly and/or

may not have the correct pressure relief valve

for proper lubrication.

7. Install the new oil lter on the engine. Turn the

lter clockwise until the rubber gasket contacts

the sealing surface, then tighten an additional

3/4 to 1 turn.

8. Reinstall the drain plug. Make sure it is tight-

ened to 10 lb·ft (14 N·m).

9. Fill the crankcase through the oil ller tube (dip-

stick opening) with new, clean oil. Use only

crankcase lubricants recommended by the en-

gine manufacturer. Refer to Specications in

this manual or the engine owner’s manual. Use

the recommended oil viscosity for the expected

ambient temperature. Oil with the correct vis-

cosity will aid starting in cold weather and assure

proper lubrication in hot weather. Fill up to, but

not above, the “F” mark on the dipstick.

Crankcase capacity is 1.85 quarts (1.75 liters)

plus 1/2 pint (0.24 liters) for the new oil lter.

IMPORTANT: Check the dipstick reading be-

fore adding the last 1/2 pint of oil and ll only to

the “F” mark. DO NOT overll the crankcase

(oil above “F” mark) as this CAN result in en-

gine overheating, loss of power, and possible

engine damage.

10. Start the engine and check for oil leaks around

the oil lter. Stop the engine, recheck the oil

level, and add oil if necessary. (When the en-

gine is rst operated with a new oil lter, the oil

level drops slightly as the lter is lled with oil.)

Mower Deck Gearbox Lubrication

NOTE: These instructions apply to all mower decks

with gear-driven blades. Refer to DS52 or DS62

Mower Deck Lubrication in this section for the

DS52 or DS62 deck with belt-driven blades. Refer

to Mower Deck Spindle Lubrication in this section

for the DS42 Belt Drive deck with belt-driven blades.

On gear driven decks, the mower deck gearboxes

(tee gearbox and blade drive gearboxes) are con-

nected as a unitized as sembly, and oil ows freely

between them. The gear boxes are permanently lu-

bricated (oil lled) and sealed requiring no sched-

uled lubrication. Howev er, the gearbox oil seals

should be checked every 25 hours for indication of

an oil leak; particularly the lower seals on the

blade drive gearboxes should be inspected, since

they operate in a dirty en vironment. If an oil leak is

noted, replace the oil seal and relubricate the gear-

box assembly as follows:

1. Remove gearbox cover (footrest). Deck orien-

tation should be the normal operating position.

Loading...

Loading...