FX66, FX85, FX110, FX140

PTO Skidding Winch

Attaching Winch to Tractor

19

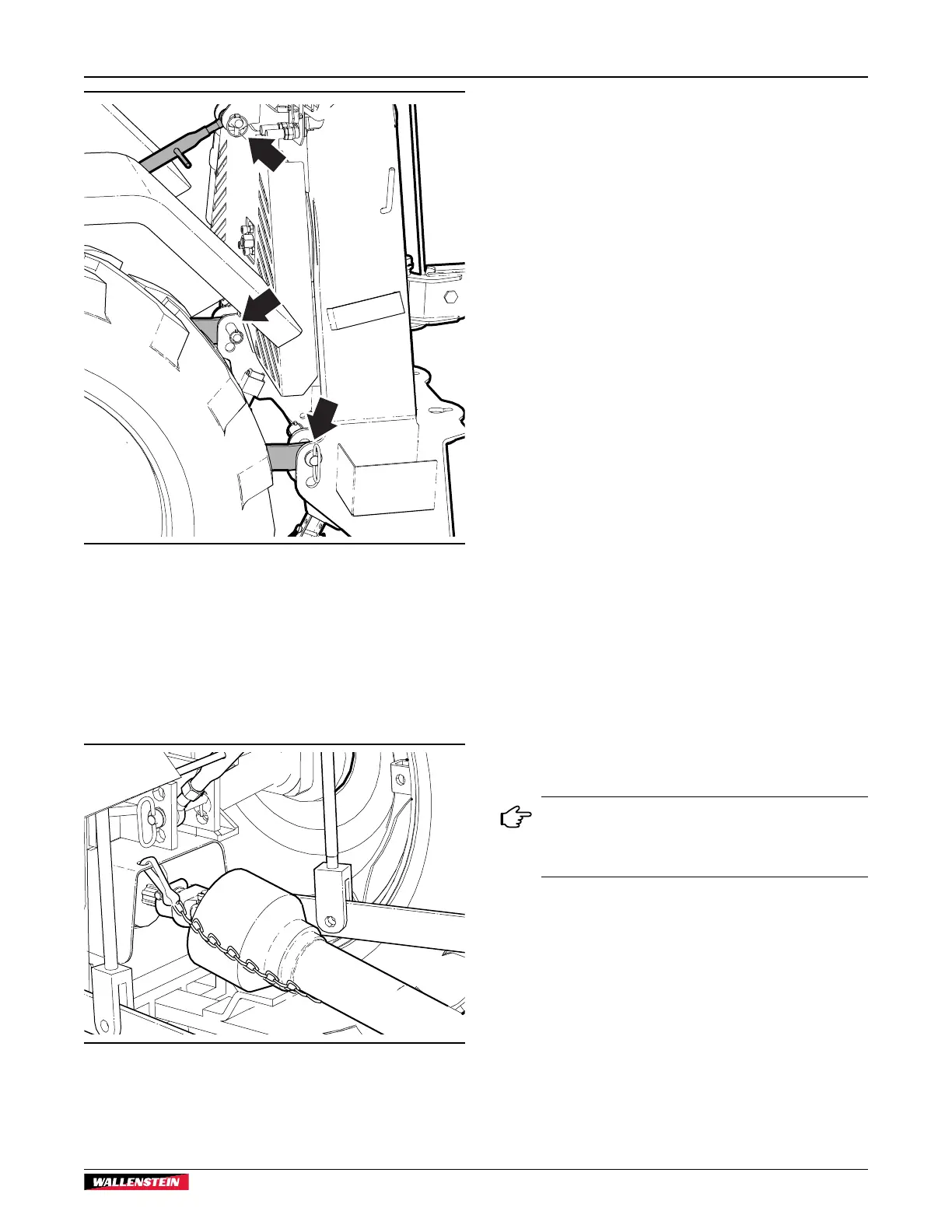

Fig. 8 – Winch Attached

9. Slide the collar back on the PTO shaft yoke. Align the

splines and slide the yoke on the tractor PTO.

10. Release the collar and make sure the locking pin clicks into

position.

11. Attach the shield anchor safety chain to an adjacent frame

member. The chain keeps the integral journal shield from

spinning.

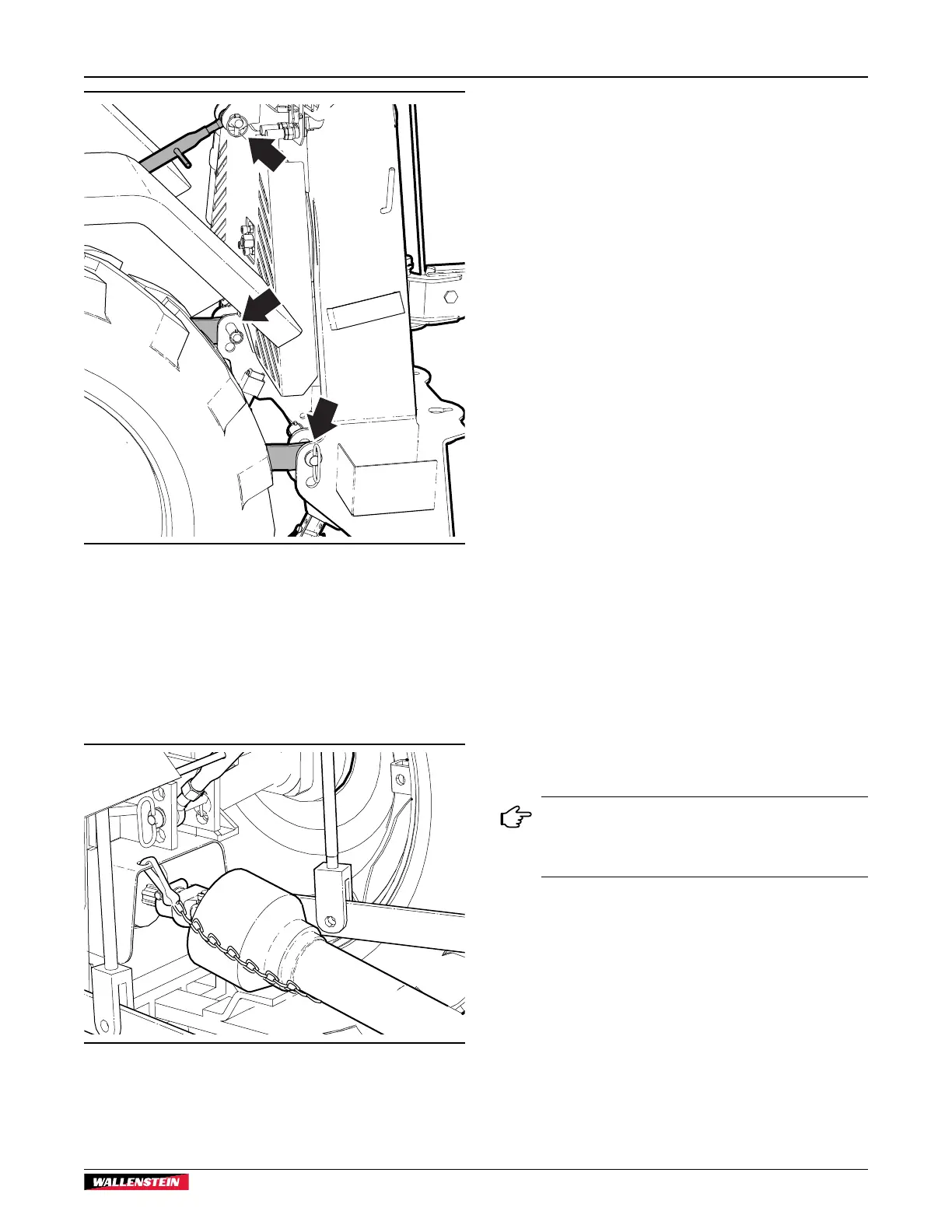

Fig. 9 – PTO Shaft Installed

12. Raise winch support legs to the storage position. Insert

snap lock pins.

13. Start the tractor and slowly raise the machine up through

its working range to make sure the telescoping portion of

the PTO shaft does not bottom out.

To detach winch from the tractor, reverse the above steps.

4.1 Winches with Remote Control

FX85R, FX110R and FX140R models include a wireless remote

winch control. The system consists of a hand-held transmitter

control and a receiver mounted on the winch.

For the remote to function, the following electrical and hydraulic

connections to the winch must be made.

Electrical Connection

• A 12 VDC, 1.5 amp power source is required from the

tractor electrical system.

• The white wire from the receiver should be connected to

positive, black to ground.

• Connectors are not supplied on the wire ends. Wire ends

are supplied bare to permit different adaptations.

Hydraulic Connection

• A valve on the winch controls the winch clutch. The system

is designed for an open-center hydraulic system. Oil flow

required is 1–2 gpm (3.8–7.5 L/m). This oil flow rate

provides the best starting/stopping speeds to prolong rope

life.

• The 1/2" pressure and return hoses have quick-disconnect

ends and are connected to the tractor rear remote power

supply.

• The hoses have colored, protective caps to indicate

function. Red is pressure and blue is return.

In the event pressure and return hoses are not

identifiable, check the connection on the control

valve. 'R' is indicated on the return port. 'P' is

indicated on the pressure port.

Loading...

Loading...