Instruction Handbook KL

Chapter 5

BA KL V11 en 10/2014 page 5-1

Commissioning 5

5.1.1 Set up commissioning

Rotating parts or pressurised spout liquids can cause fatal injuries.

Possible dangerous situation: Severe or fatal injuries.

Do not work on rotating pump!

Only qualified personnel must to commissioning the pump.

5.1.2 Pump

Normally, the stator has been preserved by means of silicon oil. If the medium to be pumped is not

compatible with silicon, the pump must be cleaned before it is first taken into service.

5.1.3 Shaft seal system

1. Check shaft seals (design data sheet).

2. LWD shaft seal: Is the vent plug screwed? Is the seal filled correctly?

3. Are connect double acting mechanical seals to a lock pressure system?

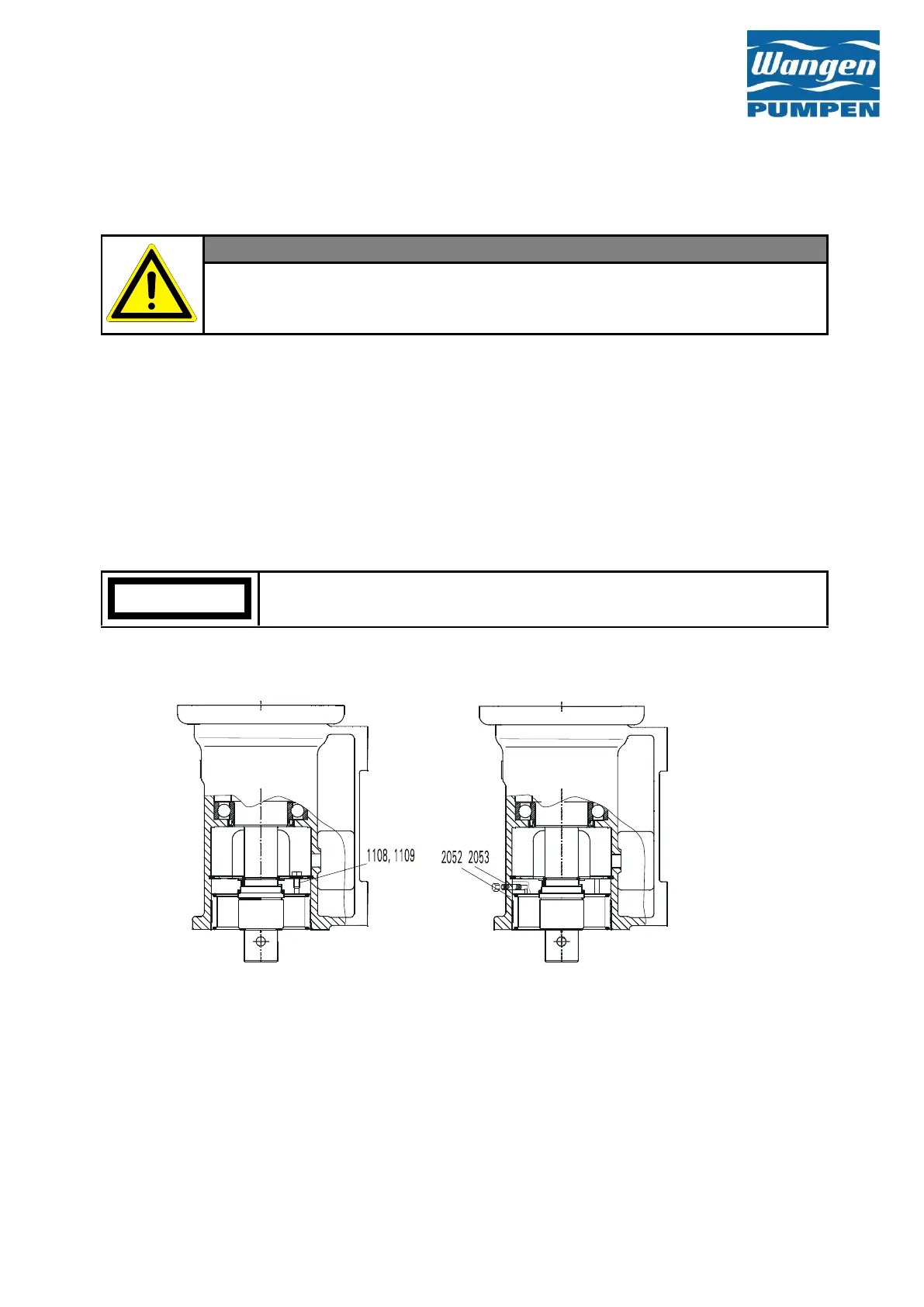

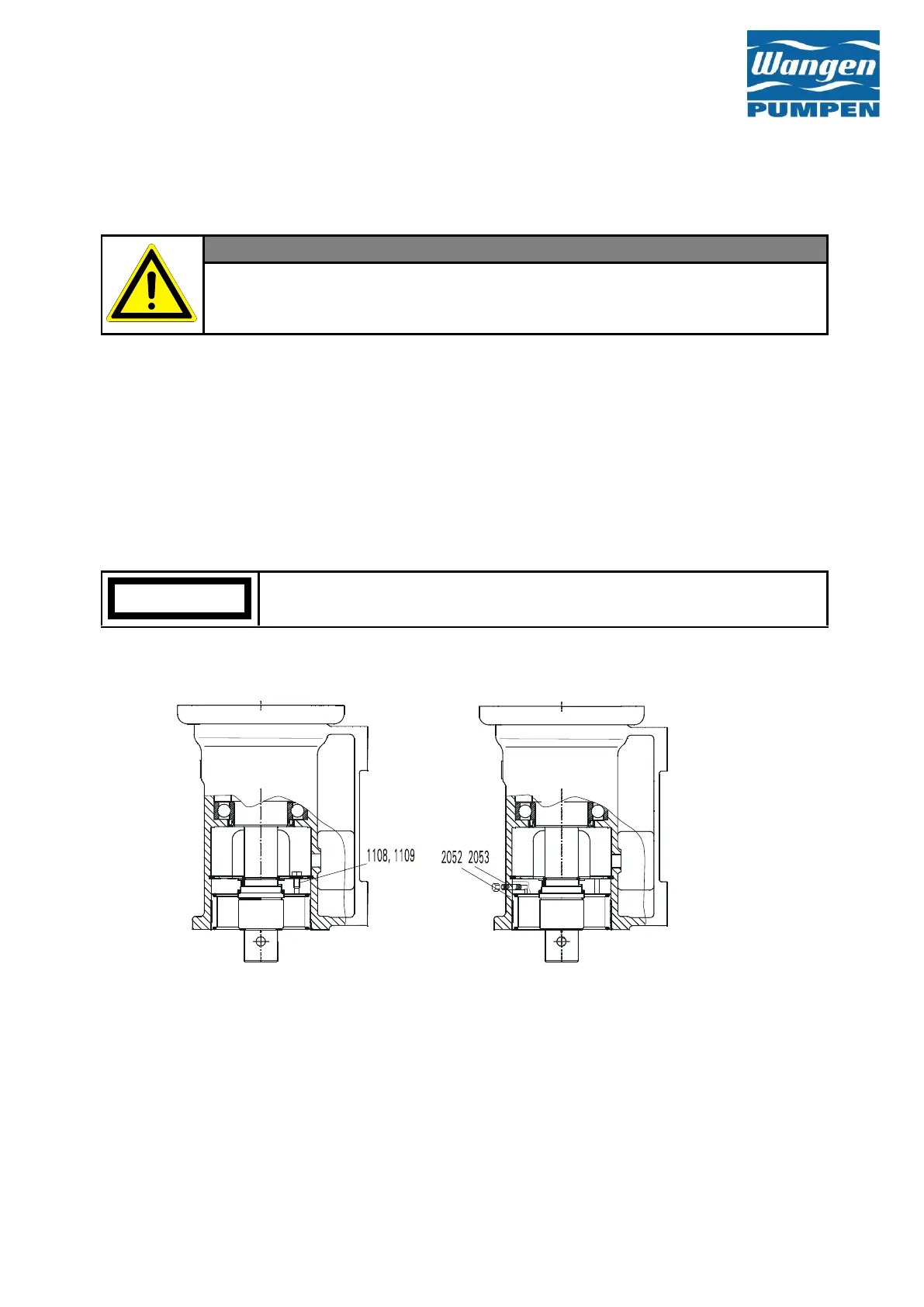

Ventilated single mechanical seal at vertical pumps and verticaly mounted pumps during

commissioning. (Ventilation into bearing chair; breather plug 1108 or cover nut 2052)

KL 50 – 100 KL 30

Pumps with mechanical seal (dependent on direction of rotation mechanical seals) are to

be used exclusively in the fixed rotational direction. A false direction of rotation could

destroy the sealing unit!

Before operating the double mechanical seals you have to connect it to a locking pressure

system. An operation without locking medium could destroy the mechanical seal.

Pumps with plug-in shaft or a quick change connection must be driven in a left hand

direction. The contra wise direction of rotation will drive out the rotor.

Loading...

Loading...