Tension control system X2DRV

29/08/2012

X2DRV Installation & Operation Manual Page 5 of 5

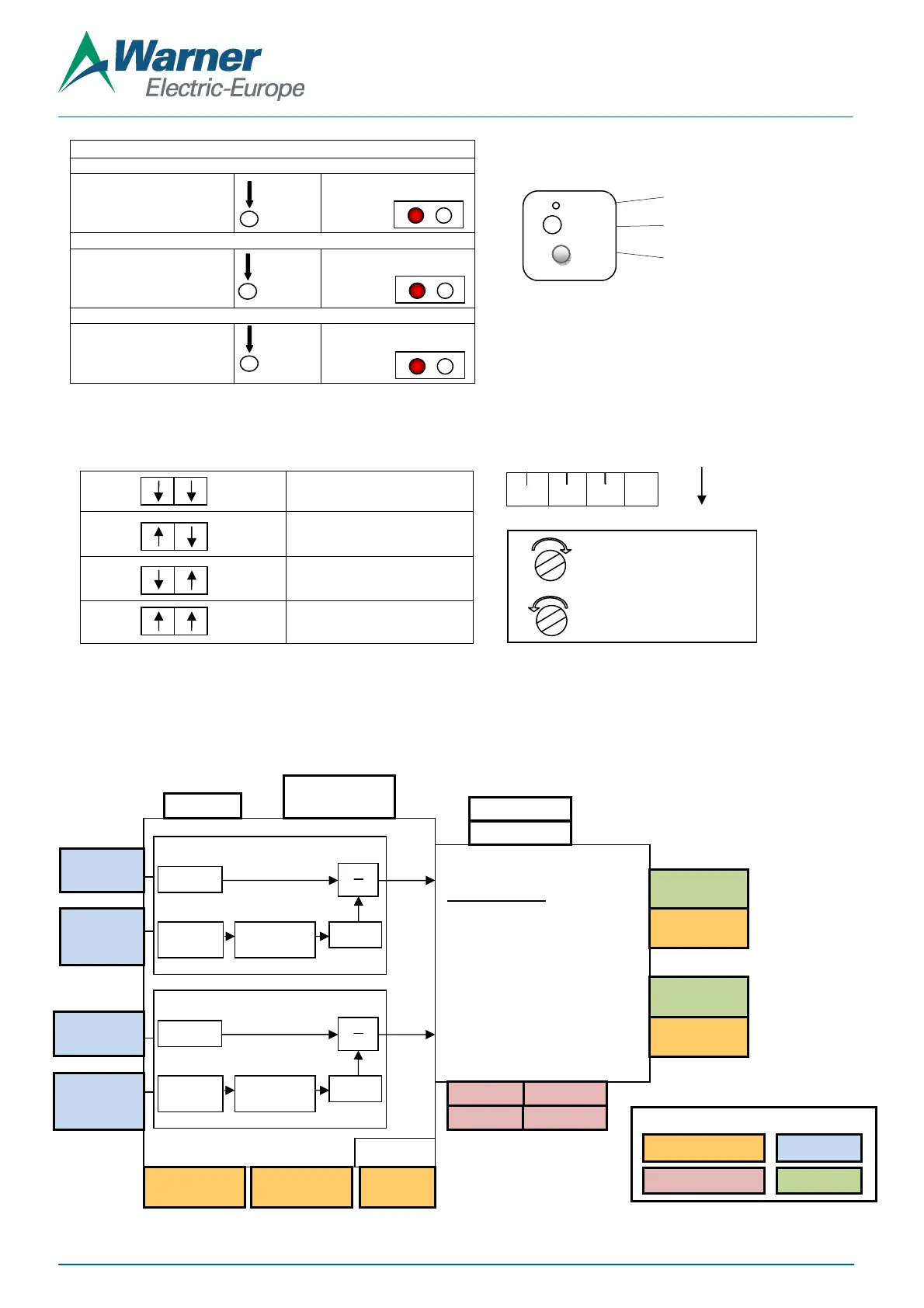

10. (Optional): The frequency adjustment changes the modulation frequency to eliminate brake “hum” or “howl” when the brake is

stationary. The frequency is factory set and normally requires no adjustments. Set the frequency as describe below with the red

switches below the chassis:

11. Double check all wiring connections per figure 2 and insure all terminals are tight

Note: If an over-load occurs (current 4A more) the Driver output will shut down and the red LED will turn ON. To reset the system remove

power to the Driver and turn it on again.

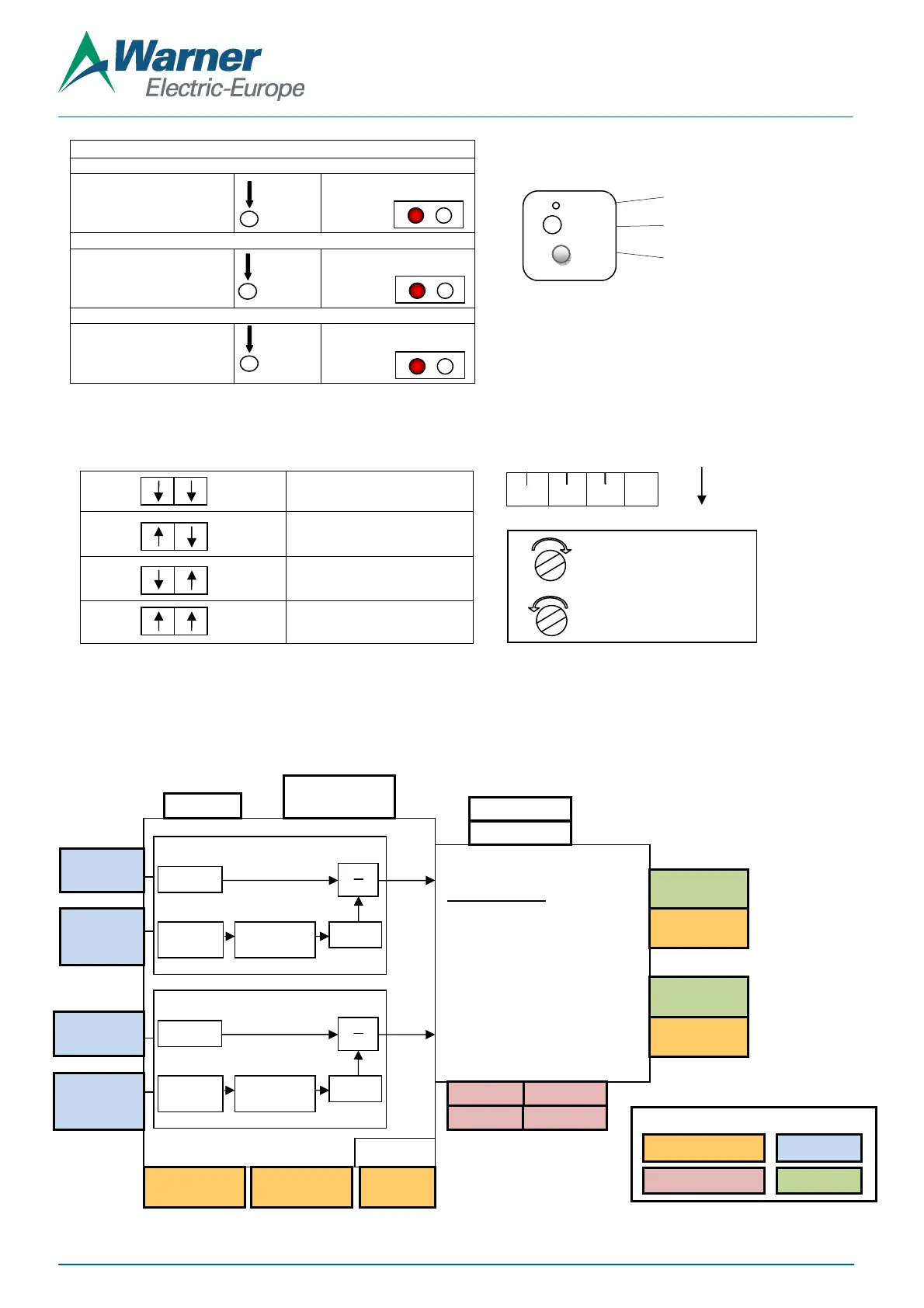

X2DRV Block Diagram:

“Teachable Span” calibration procedure

With the Auxiliary wired to Ana1

or Ana2

Press Cal button >5s.

Put Min to Ana1 or Ana2

Short press to valid: Min is learnt

Put Max to Ana1 or Ana2

Short press to valid: Max is

learnt and calibration is done

Set 0: Between 250 and 750 HZ

Set 1: Between 1000 and 3000 HZ

Set 2: Between 2500 and 7500 HZ

Set 3: Between 4250 and 10

(default)

V/I

F1

F2

Red LED on

Slow flashing

Figure 6: Anti-residual setting and calibration

Cal

Cal

Cal

>5s

Quick flashing

Turn the trim pot clockwise

to increase the frequency

counterclockwise to decrease

Power Layers

OUTPUT Control:

Pulse width modulated 4 Amps

with Anti-residual Mode

24V DC +/- 5%, 4A

Frequency

or 4-20mA

or 4-20mA

or 4-20mA

or 4-20mA

Open Loop Digital Control

X Gain

Prop.2

Open Loop Digital Control

X Gain

Prop.1

Hardware interface

Digital Input (Active low)

Analog Input

Analog Output

Setting

Cal

AntiR

LED

Potentiometer for Anti-residual setting

State LED

Auxiliary Input Calibration: Ana1 & Ana2

Loading...

Loading...