6 Components

6.1

Components

of

the Heater

6.1.1

Electric Motor (Drive) with Combustion Air Fan

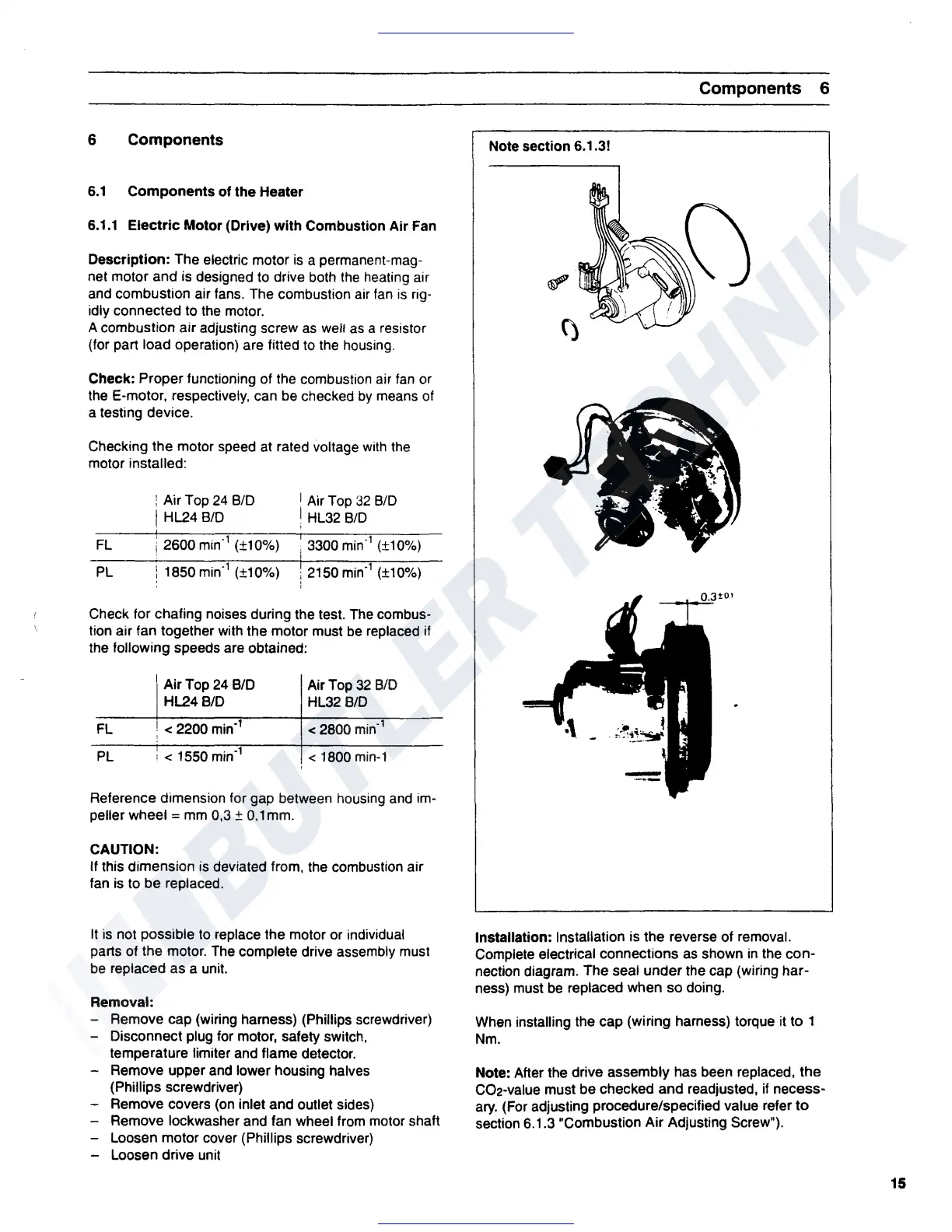

Description: The electric motor

is

a permanent-mag-

net motor and is designed to drive both the heating air

and combustion air fans. The combustion air

fan

is

rig-

idly connected to the motor.

A combustion air adjusting screw

as

well

as

a resistor

(for part load operation) are fitted to the housing.

Check: Proper functioning of the combustion air

fan

or

the E-motor, respectively, can be checked

by

means of

a testing device.

Checking the motor speed at rated voltage with the

motor installed:

FL

PL

: Air Top

24

8/D

I HL24 8/D

i 2600 min·

1

(±10%)

; 1850 min·

1

(±10%)

I Air Top

32

8/D

I HL32 8/D

. 3300

min·

1

(±10%)

i

! 2150 min·

1

(±10%)

Check tor chafing noises during the test. The combus-

tion air tan together with the motor must

be

replaced if

the following speeds are obtained:

1

Air Top

24

8/0

Air Top

32

8/0

HL24 8/D

HL32 8/D

FL

! < 2200 min-

1

< 2800

min·

1

PL

, < 1550 min·

1

< 1800

min-1

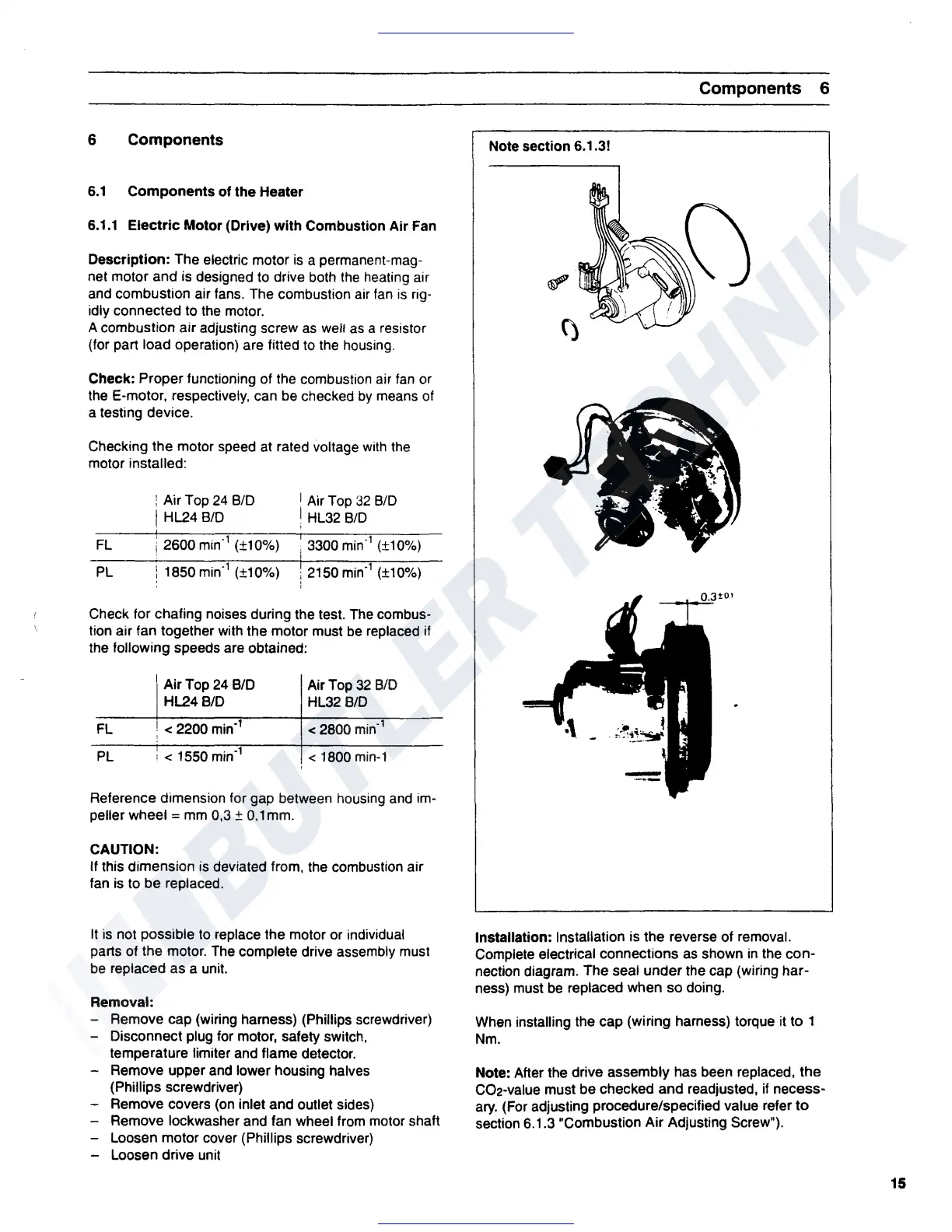

Reference dimension tor gap between housing and im-

peller wheel

=

mm

0,3 ±

0.1

mm.

CAUTION:

If this dimension is deviated from, the combustion air

tan is to be replaced.

It

is not possible to replace the motor or individual

parts of the motor. The complete drive assembly must

be replaced as a unit.

Removal:

- Remove cap (wiring harness) (Phillips screwdriver)

Disconnect plug for motor,

safety

switch,

temperature limiter and flame detector.

Remove upper and lower housing halves

(Phillips screwdriver)

Remove covers (on inlet and outlet sides)

Remove lockwasher and fan wheel from motor shaft

Loosen motor cover (Phillips screwdriver)

Loosen drive unit

Components 6

Note section 6.1.3!

Installation: Installation is the reverse of removal.

Complete electrical connections as shown

in

the con-

nection diagram. The seal

under

the cap (wiring har-

ness) must

be

replaced when so doing.

When installing the cap (wiring harness) torque it to 1

Nm.

Note:

After the drive assembly has been replaced,

the

C02-vaiue must

be

checked

and

readjusted,

if

necess-

ary.

(For adjusting procedure/specified value refer

to

section 6.1.3 "Combustion Air Adjusting Screw").

15

Loading...

Loading...