Part number 550-143-010/1021

12

GV90+ series

2

gas-fired water boiler – boiler manual

Install water piping

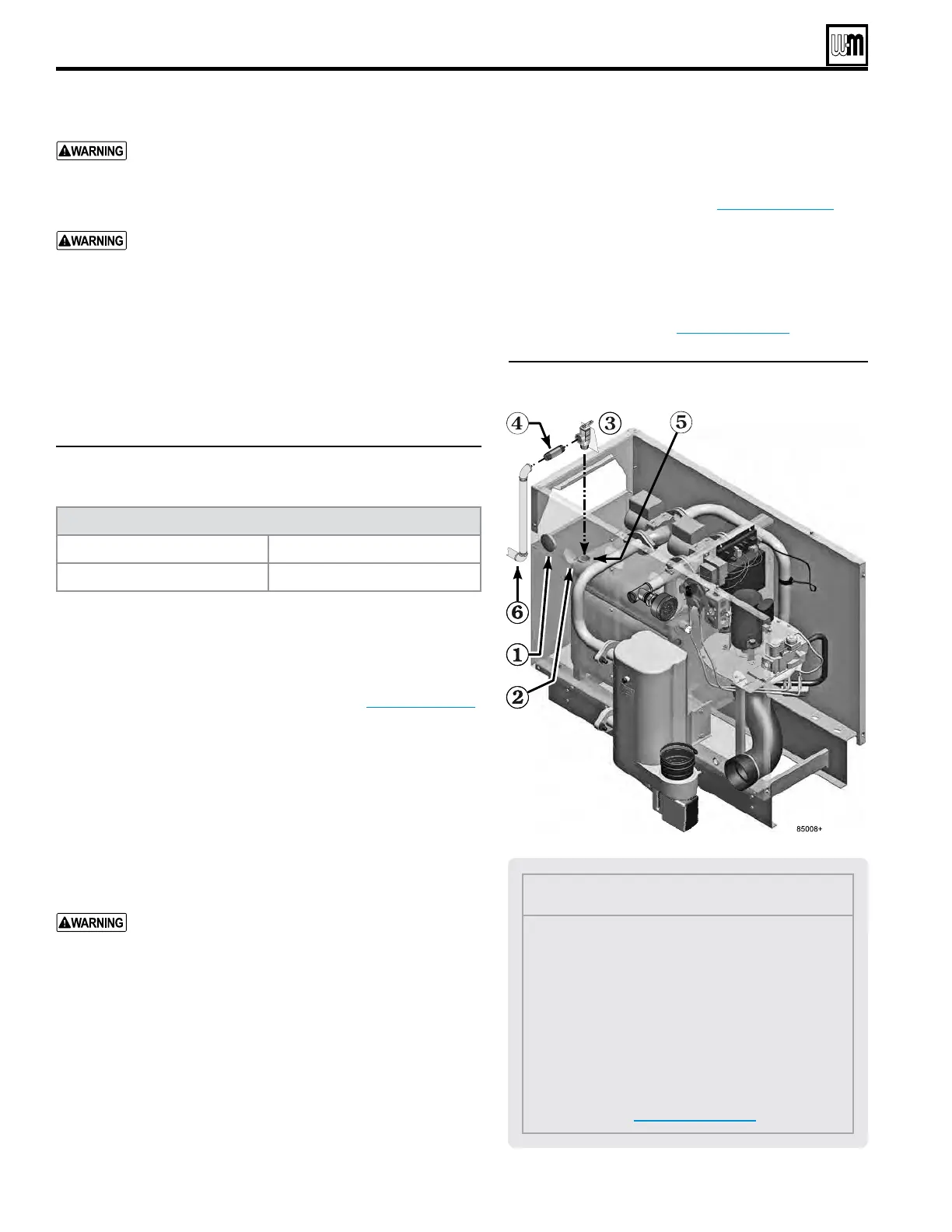

Legend

1 Jacket plug for unused relief valve jacket opening.

2 Jackets are provided with two relief valve open-

ings because each jacket size is used for two boiler

sizes. Cover the unused opening with the plug

provided.

3 Boiler relief valve (from accessory bag)

4 ¾” x 3” nipple, provided in accessory bag

5 ¾” relief valve tapping in back section

6 Connect minimum ¾” discharge piping to relief

valve.

See Figure 13, page 13.

Air separator

Install an air separator in the piping as shown in this

manual. For single-zone systems, install the air separator

in the return piping as shown in Figure14,page14. is

allows mounting the automatic air vent and expansion tank

o of the separator.

Install relief valve

1. Install relief valve ONLY as shown in Figure12.

2. Connect discharge piping to safe disposal location,

following guidelines in Figure13,page13.

Use two wrenches when tightening water piping at

boiler

, using one of the wrenches to prevent the boiler

interior piping from turning. Failure to support the boiler

piping connections to prevent them from turning could

cause damage to boiler components.

e cast iron heat exchanger return temperature must be

kept at or above 140°F during all times of operation to

prevent possibility of corrosion due to condensation. is

is done automatically, using the boiler's internal circula-

tors. DO NOT remove or tamper with these circulators.

Failure to comply could result in severe personal injury,

death or substantial property damage.

General piping information

Minimum pipe size for boiler loop piping

Figure 11 Provide boiler loop piping no smaller than listed

below (based on 20°F temperature rise)

Boiler loop pipe size, Minimum

GV90+ 3 or 4 1”

GV90+ 5 or 6 1¼”

Additional limit controls

Following standard industry practices, if installation is to comply with

ASME or Canadian requirements, an additional high temperature

limit

may be needed. Consult local requirements for other codes/

standards to determine if needed. Wire as shown in Figure67,page56 .

• Install a manual reset high temperature limit between the boiler

and the isolation valve.

• Wire the manual reset limit in series with the boiler limit control.

• Set the manual reset limit control at least 20°F above the boiler

limit control setting (maximum setting 220°F).

Low water cut-o

A low water cuto device is required when boiler is installed above

radiation level or by certain state or local codes or insurance compa-

nies. e boiler has a pre-installed water temperature/LWCO sensor.

If boiler is connected to heating coils located in air han-

dling units where they can be exposed to refrigerated

air, use ow control valves or other automatic means to

prevent gravity circulation during cooling cycle. Circu-

lation of cold water through the boiler could result in

damage to the heat exchanger, causing possible severe

personal injury, death or substantial property damage.

Backow preventer

Where required by codes, install a backow preventer in the cold

water ll line, as shown in suggested piping diagrams on following

pages. Install a check valve if a backow preventer is not installed.

Figure 12 Install pipe relief valve

Loading...

Loading...