Do you have a question about the Weil-McLain 88 and is the answer not in the manual?

Specifies minimum clearances to combustible materials and for servicing.

Details when and how to lay a level concrete or brick foundation.

Details requirements for combustion and ventilation air openings to interior spaces.

Specifies minimum free areas and locations for interior air openings.

Describes methods for providing combustion air from outdoors via openings.

Explains using a combination of indoor and outdoor openings for combustion air.

Covers engineered installations and mechanical air supply systems.

Details specifications for louvers, grilles, and screens used for air openings.

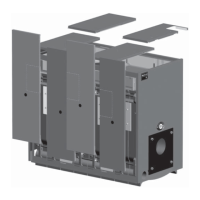

Instructions for lifting and positioning a packaged boiler.

Instructions for positioning a block-assembled boiler.

Guides on applying sealing rope and positioning the back boiler section.

Procedures for joining intermediate boiler sections with draw rods.

Steps for installing fittings and plugging tappings before pressure testing.

Procedure for filling the boiler and conducting the pressure test.

Steps to attach the burner mounting plate to the front section.

Procedure for installing observation port assemblies on front and back sections.

Instructions for inserting flue HXT-bars into the boiler sections.

Provides general guidelines for system water supply and return piping.

Details on connecting supply, return, and expansion tank piping for water boilers.

Outlines requirements for steam boilers, including Hartford loop piping.

Specifies minimum header height and other steam piping considerations.

Lists parts that must be on or off the boiler before jacket installation.

Instructions for locating and removing jacket parts from their packaging.

Steps for attaching jacket support brackets and side/front/rear channels.

Procedures for installing furnished controls like relief valves and low water cut-offs.

Guidelines for setting high and low temperature limits for dual limit controls.

Instructions for installing steam pressure controls, high limit, and water level controls.

Specific requirements for vertical installation and discharge piping of relief valves.

Overview of boiler operation with positive overfire pressure and draft types.

Guidelines for selecting material and constructing metal breeching according to codes.

Steps for mounting the burner, ensuring a gas-tight seal, and leveling.

Guidance on wiring the burner and boiler controls according to electrical codes.

Recommendations for water treatment and antifreeze for water boilers.

Factors for sizing gas piping, including pressure and material requirements.

Guidelines for installing fuel oil piping, including anti-syphon devices and materials.

Procedures for adjusting the burner for optimal combustion and flue draft.

Process for cleaning oil from newly installed steam boilers for proper operation.

Steps to ensure the boiler is sealed gas-tight to prevent flue gas leakage.

Safety precautions for removing ceramic fiber front/cleanout plate materials.

Safety precautions for handling fiberglass insulation in jacket and other components.

Table detailing I=B=R gross output, efficiencies, and capacities for various models.

Provides detailed dimensional data and tapping locations for each boiler model.

List of all boiler parts with descriptions, item numbers, and part numbers.

| Brand | Weil-McLain |

|---|---|

| Model | 88 |

| Category | Boiler |

| Language | English |

Loading...

Loading...