9

up the machine. Set the welding mode switch

(7) to ‘Lift TIG’.

7.5 Select the required output current using the

current control knob (5). You are now ready to

weld!

NOTE: The WF-180MST is a DC (Direct Current)

output welder only, this means that it is unable to

TIG weld reactive metals such as Aluminium alloys

and Brass (which require AC output). DC TIG output is

suitable for steel, stainless steel and copper.

Tips & Tricks

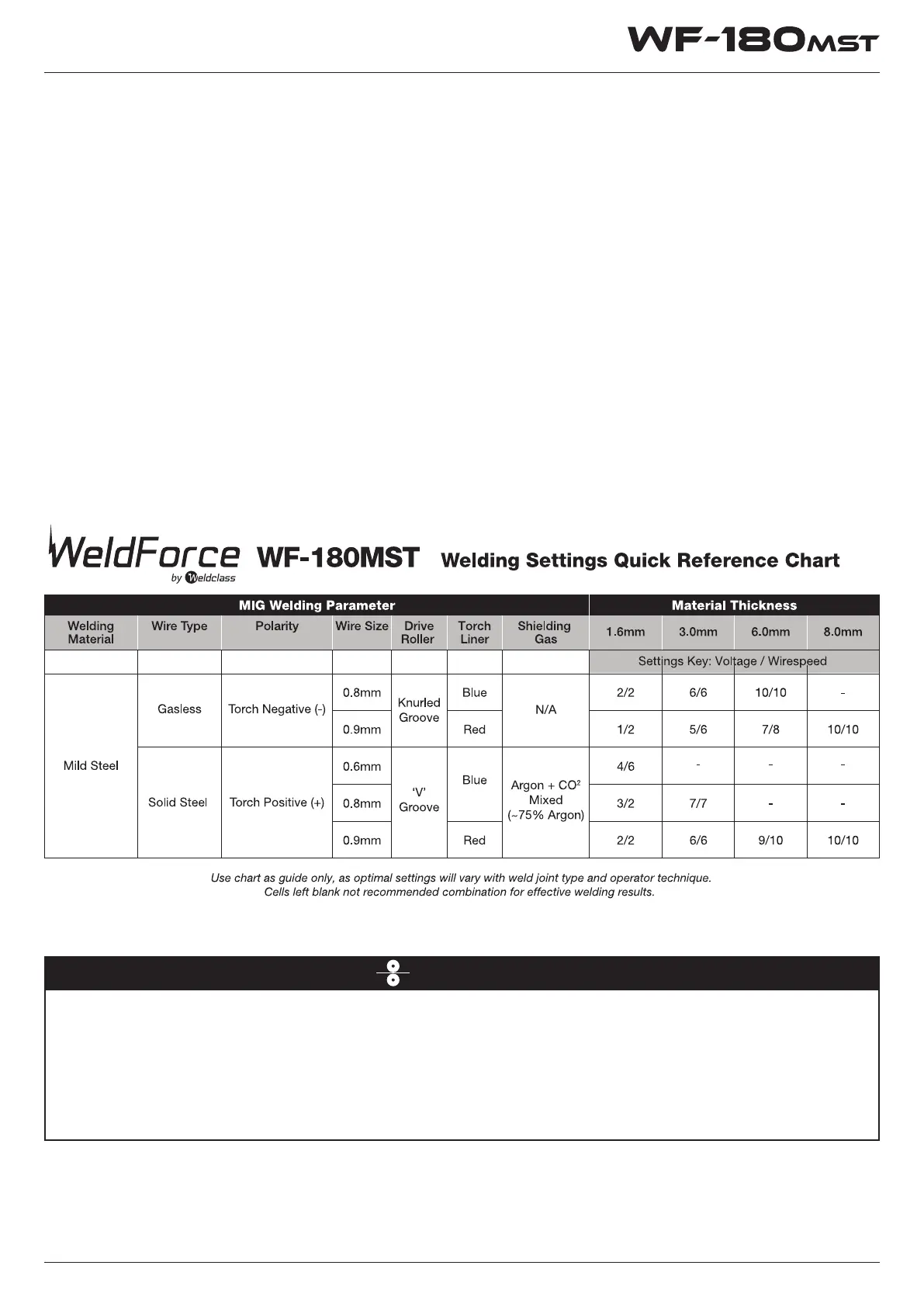

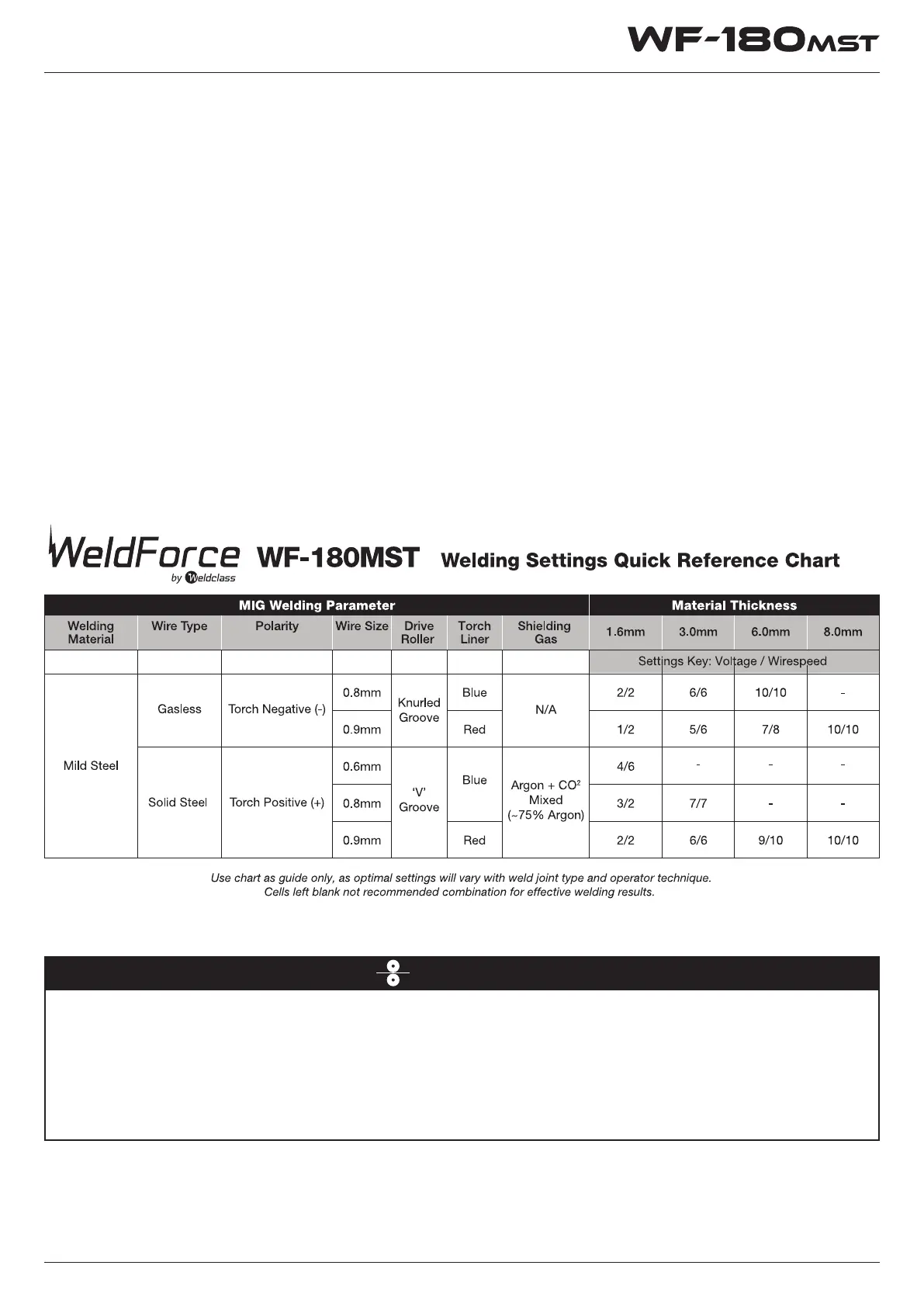

Welding Settings

Welding duty cycle is the percentage of actual

welding time that can occur in a ten minute cycle.

E.g. 20% at 160 amps - this means the welder can

weld at 160 amps for 2 minutes and then the unit

will need to be rested for 8 minutes. All duty cycle

ratings are based on an ambient air temperature of

40°

C

with 50% humidity, which is the international

standard for such a rating. In an environment with

temperature s exceeding 40°

C

, the duty cycle will

be less than stated. In ambient temperature less

than 40°

C

, duty cycle performance will be higher.

Duty Cycle Rating

Wire Jam Troubleshooting

• If wire jam occurs when the torch becomes hot, this is often because the heat causes the wire and the tip

to expand (which shrinks the hole in the tip). Using a slightly oversize tip can prevent this – eg: for 0.9mm

wire, use a 1.0mm tip.

• Do NOT over-tighten the drive roll tension – this will accelerate wear of the drive system, may distort the

wire & will cause further wire feed problems.

• Refer to page 15-16 for more troubleshooting tips.

Loading...

Loading...