Operation

The 2001NB Level Control utilizes a balanced method, whereby a

spring acting on a lever balances the weight of the displacer in the

vessel. As liquid rises in the vessel, force is made available via the

Torque Bar (16) and Fulcrum (26), to the pilot proportional to the

weight of the displaced liquid. As the liquid level rises the amount of

force increases to the pilot.

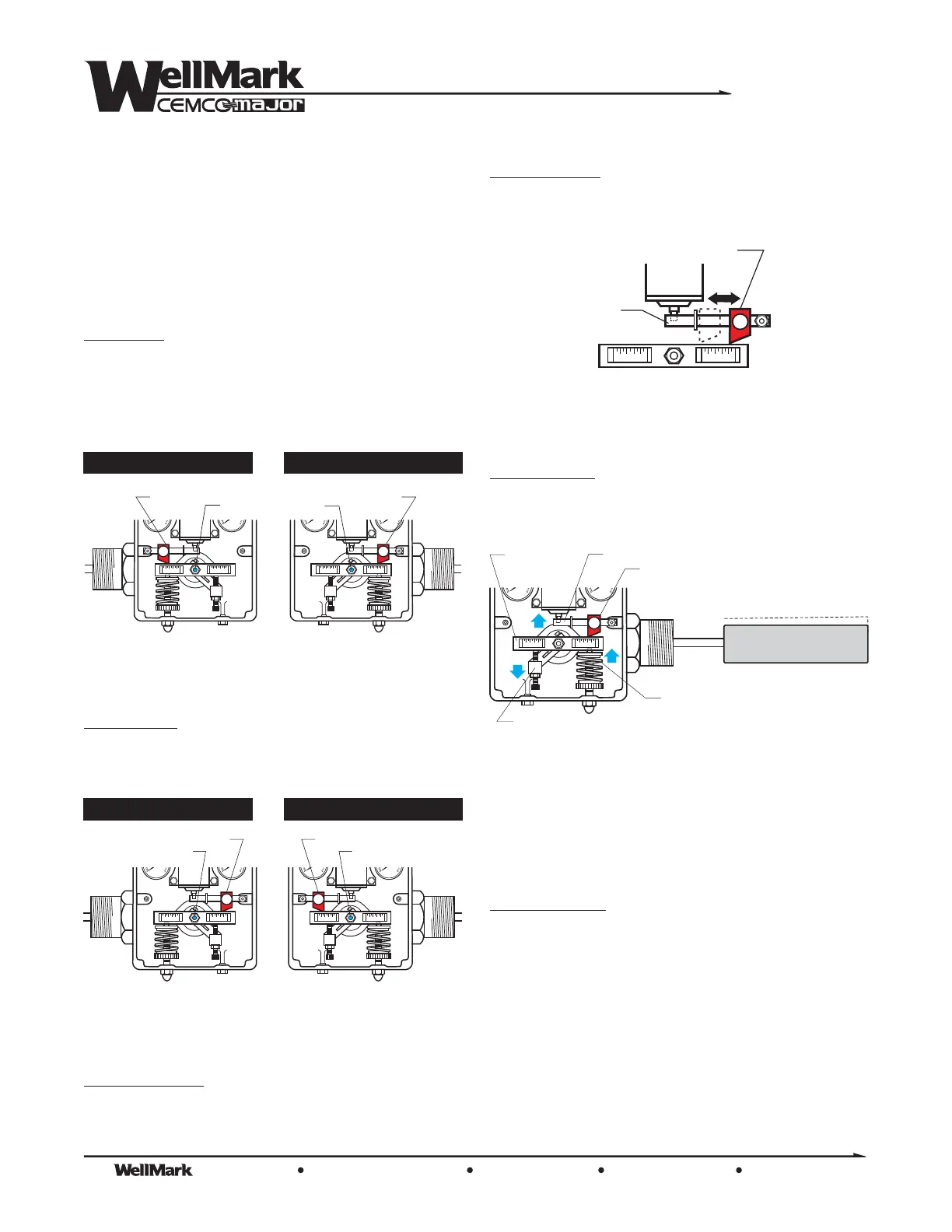

configuration, whereby rising level Pilot

output. When the unit is configured for Direct-Acting operation the

Fulcrum will be located either left or right of the pivot depending upon

whether the unit is Left Hand Mount or Right Hand Mount as

illustrated below.

configuration (rising level Pilot output)

can be accomplished by moving the Fulcrum to the opposite side as

shown below.

refers to the differential between ON and OFF.

This is determined by the position of the Fulcrum along the Torque

Bar.

Direct-Acting

Reverse-Acting

Span or Dump Span

increases

decreases

The Company, L.L.C. Oklahoma City, Oklahoma Tel: (405) 672-6660 Fax: (405) 672-6661

wellmarkco.com

© The WellMark Company • Litho USA • All registered trademarks are the property of their respective owners. • IOM-2001NB 091007

2

2001NB

Series

REVERSE-ACTING

Rising level DECREASES Pilot output

FULCRUM

PIVOT

PIVOT

FULCRUM

LEFT HAND MOUNT RIGHT HAND MOUNT

psi psipsi psi

DIRECT-ACTING

Rising level INCREASES Pilot output

FULCRUM

PIVOT PIVOT

FULCRUM

LEFT HAND MOUNT RIGHT HAND MOUNT

psi psi psipsi

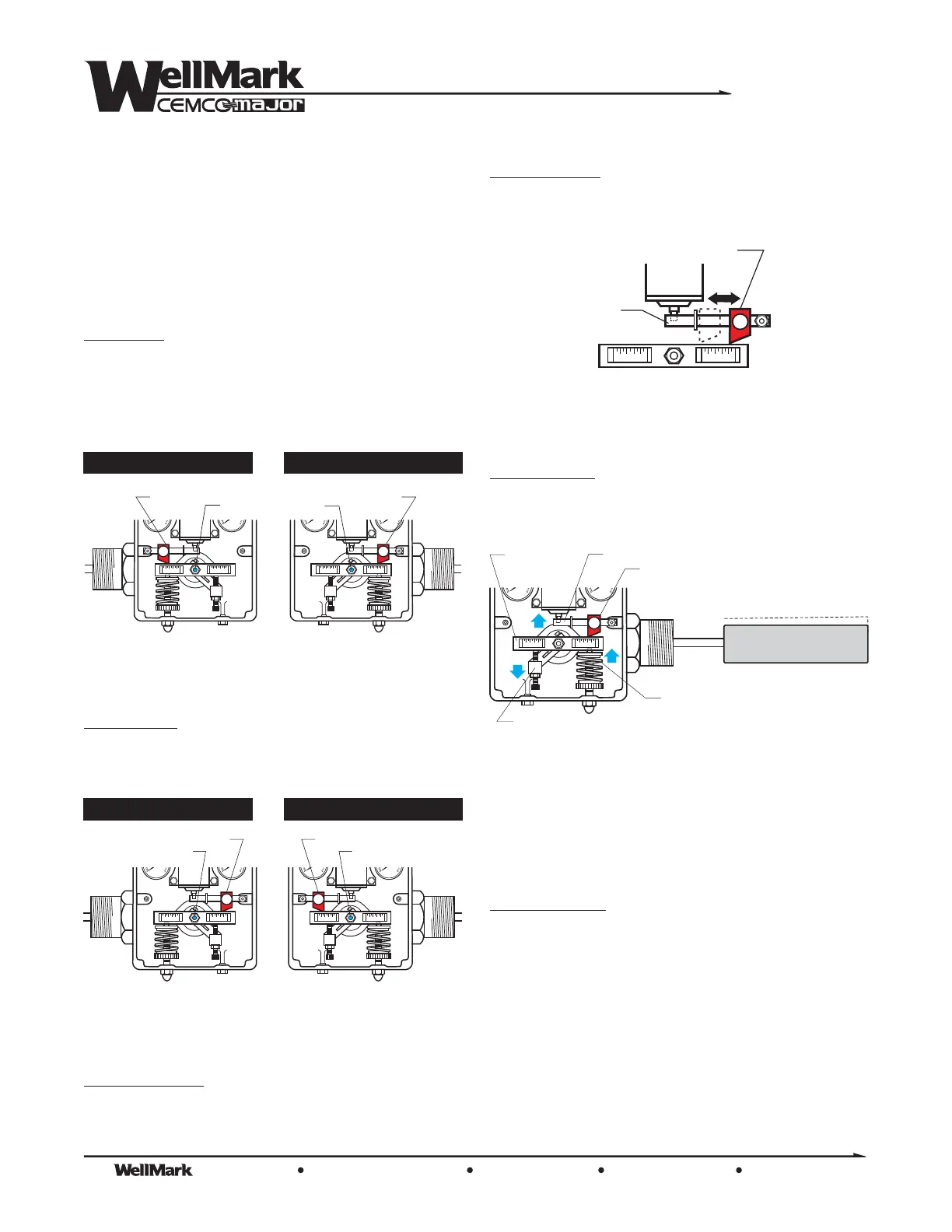

Proportional Band, when referring to a throttling control, is the ratio

of displacer actually used as compared to the overall length of the

displacer. For instance, a 50% proportional band would utilize 6” of a

12”displacer to achieve a 3-to-15 psi output.

FULCRUM

PILOT

FLAPPER

BAR

The Dump Span and Proportional Band are adjusted by moving the

Fulcrum along the Flapper Bar as necessary to achieve the desired

result.

- The Displacer’s weight is held in balance by the

Spring (21). Since the Displacer is buoyant, as the level rises the

apparent weight or of the Displacer decreases. As a result of

Level Adjustment

mass

psipsi

SPRING

ADJUSTMENT ARM

Differential force increases

as Displacer is unweighted

Rotates down, relieving

pressure on Torque Bar

Displacer’s apparent weight

decreases as fluid level rises

FLAPPER BAR

FULCRUM

PILOT

TORQUE

BAR

the rising Displacer the Adjusting Bar rotates, relieving pressure on

the Torque Bar. This results in an increase in differential Spring

force, transmitting that force to the Pilot poppet via the Fulcrum and

Flapper Bar. Increasing tension on the Spring lowers the sensed

level. Conversely, decreasing the spring force raises the sensed

level.

Some systems require control at the interface distinction between the

hydrocarbon and water. This is referred to as . It

is possible to adjust the Spring to a point at which the hydrocarbon

liquid completely envelopes the displacer without transmitting

enough force to engage the pilot and produce any output.

Water has a higher specific gravity than hydrocarbon and naturally

separates lower, with hydrocarbon liquid rising above it. When

properly adjusted, water can rise to a level on the displacer, changing

its apparent weight and causing enough force to engage the pilot,

which will then result in output. The 2001NB unit’s broad range of

control allows liquid interface sensing.

Interface Operation

interface operation

Loading...

Loading...