Startup

Assure free-travel of the Displacer and Displacer Arm by rocking the

Torque Bar by hand and observing corresponding movement of

Displacer. The Displacer Arm should be centered in the vessel

nozzle to assure that the vessel nozzle does not inhibit free

operation. Displacer Arm should be parallel to the ground at

installation.

The controller is factory-set for average level and sensitivity.

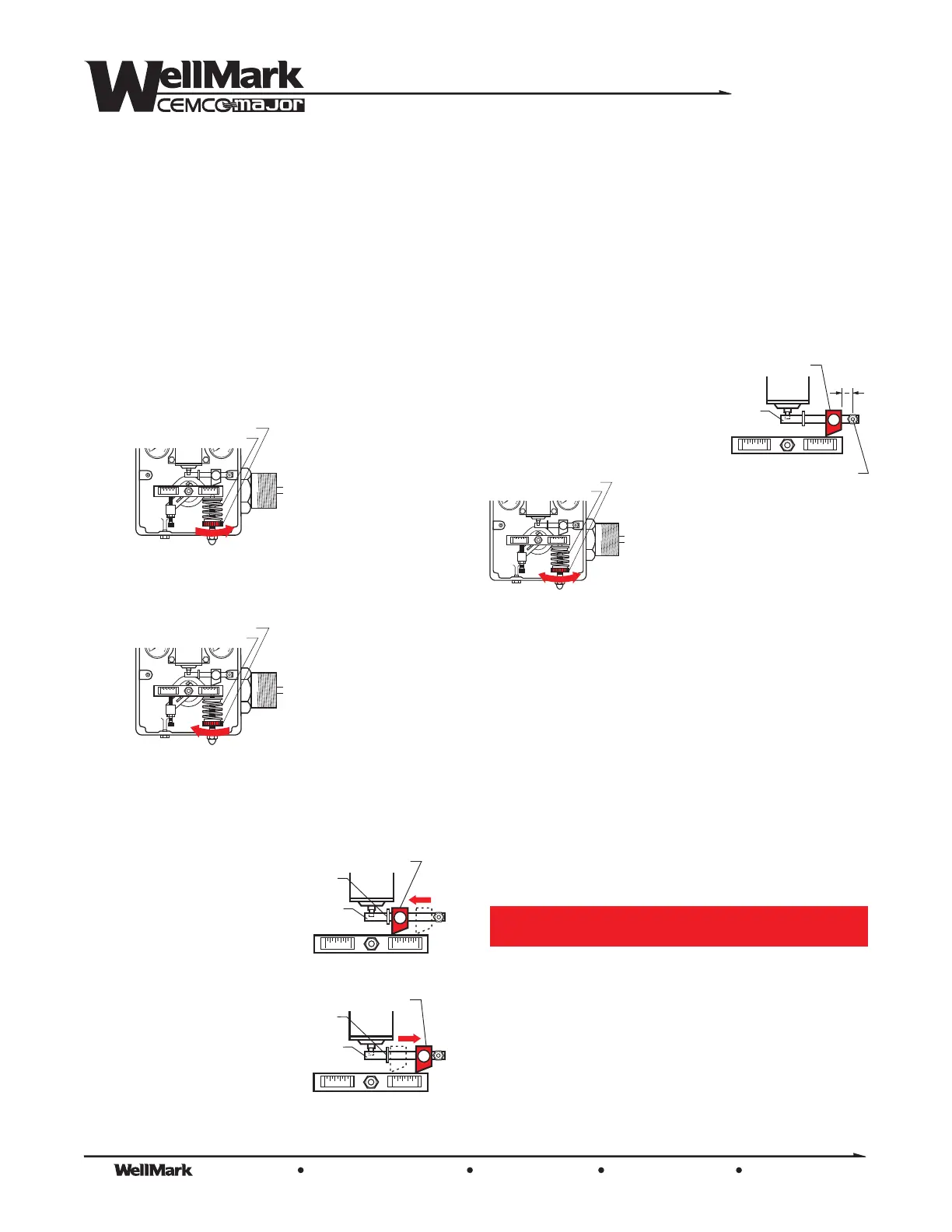

- Increase the compression of the Spring by

turning theAdjustment Wheel to the

LEVELADJUSTMENT

To DECREASE LEVEL

RIGHT.

SETTING INTERFACE LEVEL

NOTE: The

presence of foam in the interface zone may affect the accuracy

of the control.

The controller is factory-set for average level and sensitivity.

Generally speaking, interface operation is most successful when

there is a substantial differential in specific gravity between the two

liquids. Interface cannot be reliably achieved with a displacer-type

control with specific gravity differentials less than 0.1. Also, the

sensitivity of the interface control is increased by the size of the

displacer. Therefore, it is usually advantageous to use the largest

displacer available, which will fit into the vessel.

The Company, L.L.C. Oklahoma City, Oklahoma Tel: (405) 672-6660 Fax: (405) 672-6661

wellmarkco.com

© The WellMark Company • Litho USA • All registered trademarks are the property of their respective owners. • IOM-2001NB 091007

4

2001NB

Series

psipsi

DECREASE LEVEL

by increasing Spring compression

ADJUSTMENT WHEEL

SPRING

RIGHT

psipsi

ADJUSTMENT WHEEL

SPRING

psipsi

INCREASE LEVEL

by decreasing Spring compression

ADJUSTMENT WHEEL

SPRING

LEFT

To INCREASE LEVEL -

LEFT.

Decrease Spring compression by turning

theAdjusting Wheel to the

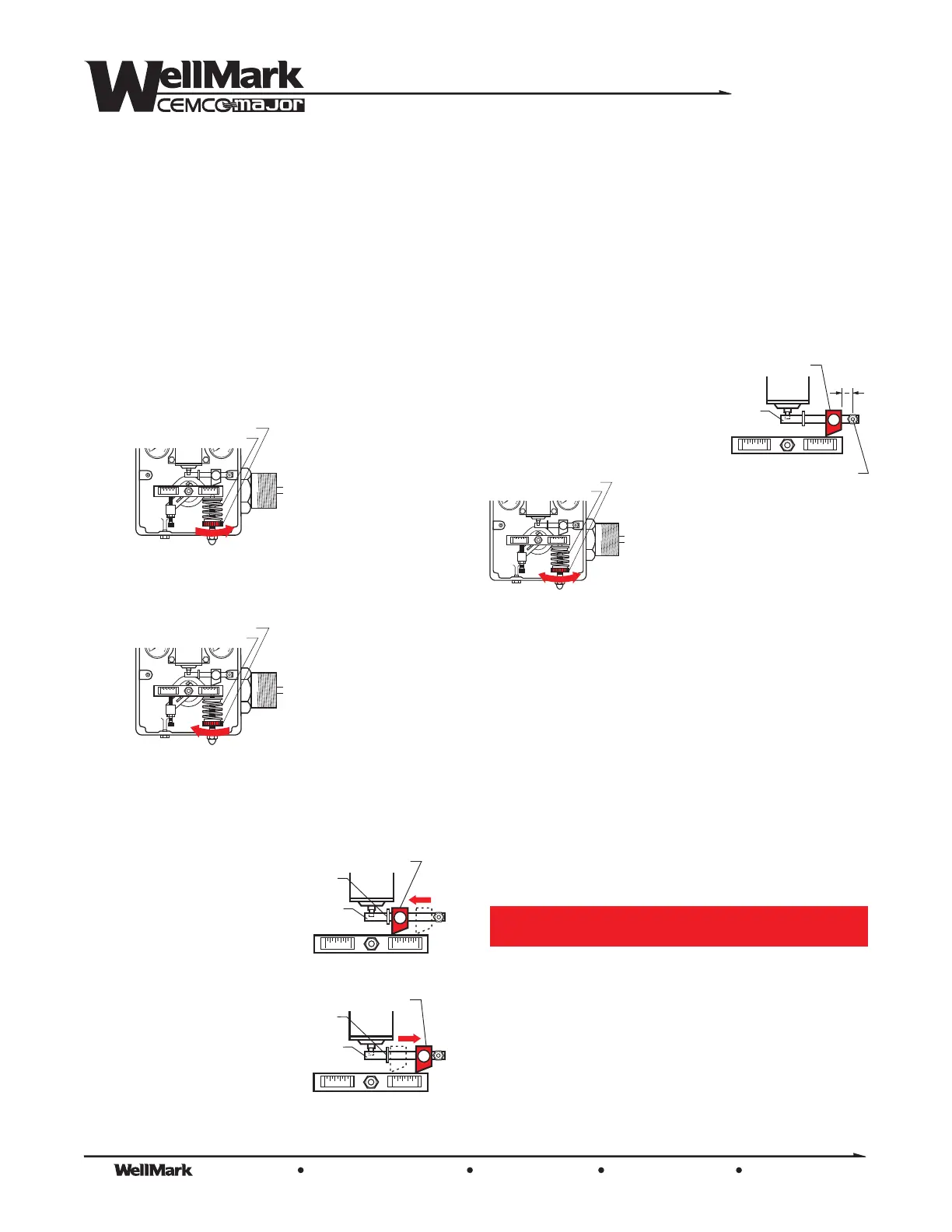

ADJUSTING PROPORTIONAL BAND (SPAN)

To DECREASE BAND

(Increase Sensitivity)

Loosen Thumbscrew on Fulcrum and position the Fulcrum along the

Flapper Bar.

Slide Fulcrum along

Flapper Bar toward

Snap Ring.

FULCRUM

PILOT

FLAPPER

BAR

SNAP

RING

FULCRUM

PILOT

FLAPPER

BAR

SNAP

RING

To INCREASE BAND

(decrease Sensitivity)

Slide Fulcrum along

Flapper Bar away from

Snap Ring.

Once desired band/span is achieved re-tighten Thumbscrew.

FULCRUM

PIVOT

PILOT

FLAPPER

BAR

1”

2

1. Set Fulcrum approx. 1/2” from

pivot pin.

Reduce Spring tension slowly by

turning the Adjusting Wheel to the

Allow the upper fluid to rise until

it completely submerges the Displacer.

LEFT.

Next, fine-tune the adjustment by turning the Adjusting Wheel to

the until an output signal is attained.

Finally, turn theAdjusting Wheel back to the until the output

signal returns to

2. Allow the lower liquid to rise until the desired interface level is

attained. Fine tune by slowly turning the Adjusting Wheel to the

until an output signal is obtained. Finally, slowly turn the

Adjusting Wheel to the until the output signal returns to

ZERO.

3. To obtain a shorter dump span, slide the Fulcrum away from the

pivot and repeat the above procedure.

RIGHT

LEFT

ZERO.

RIGHT

LEFT

Maintenance

The 2001NB Level Control is designed to provide years of reliable

service. However, build up of debris, paraffin, etc inside the

controller Body can interfere with proper functioning. A regular

maintenance program should include checking for this condition.

Prior to maintenance of the 2001NB Level Control

system must be isolated from pressure. Failure to

do so may result in personal injury, environmental

spill concerns and/or damage to equipment.

WARNING!

Loading...

Loading...