The Company, L.L.C. Oklahoma City, Oklahoma Tel: (405) 672-6660 Fax: (405) 672-6661

wellmarkco.com

© The WellMark Company • Litho USA • All registered trademarks are the property of their respective owners. • IOM-2001NB 091007

3

2001NB

Series

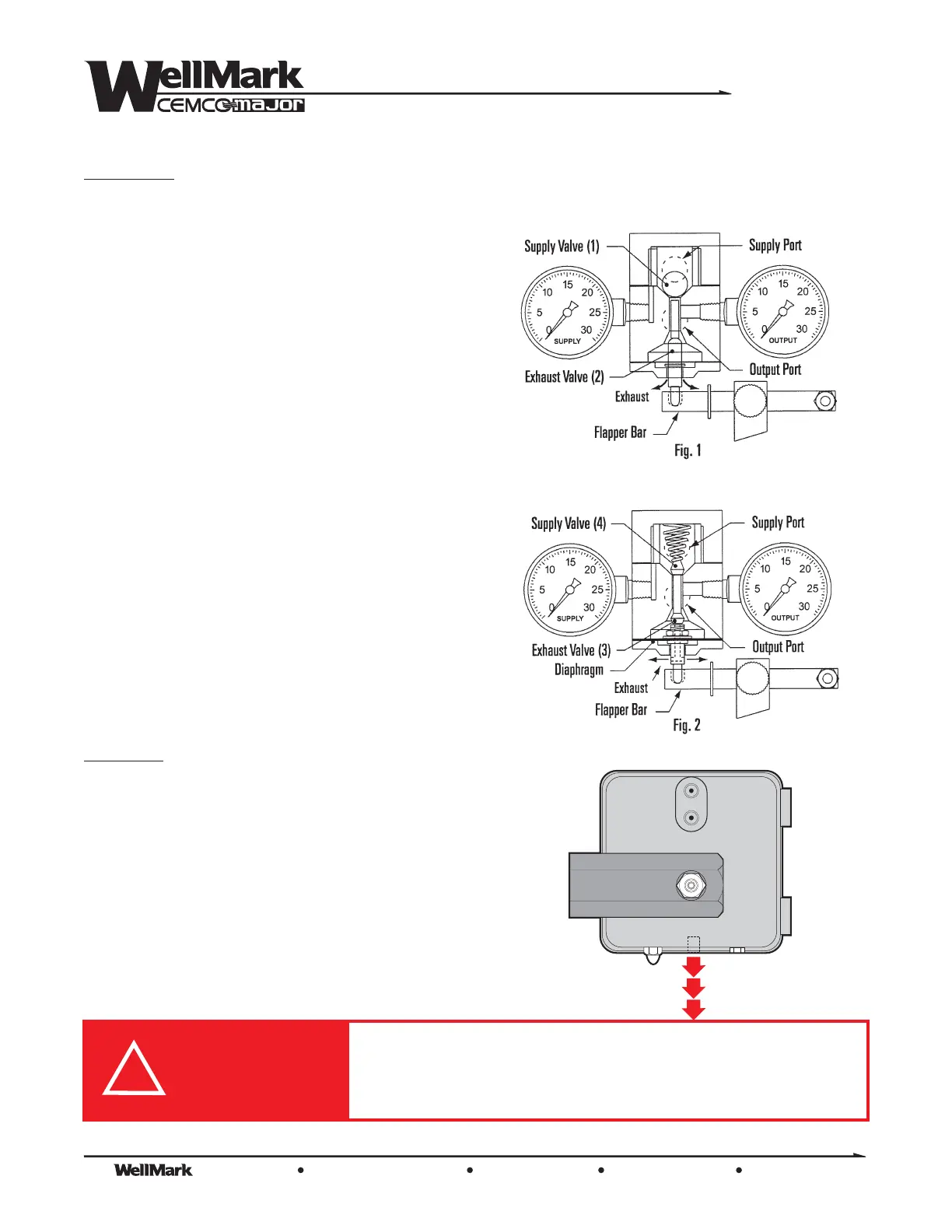

Pilot Operation

IMPORTANT!

Snap-Acting Pilot • No-Bleed On/Off FlowAction

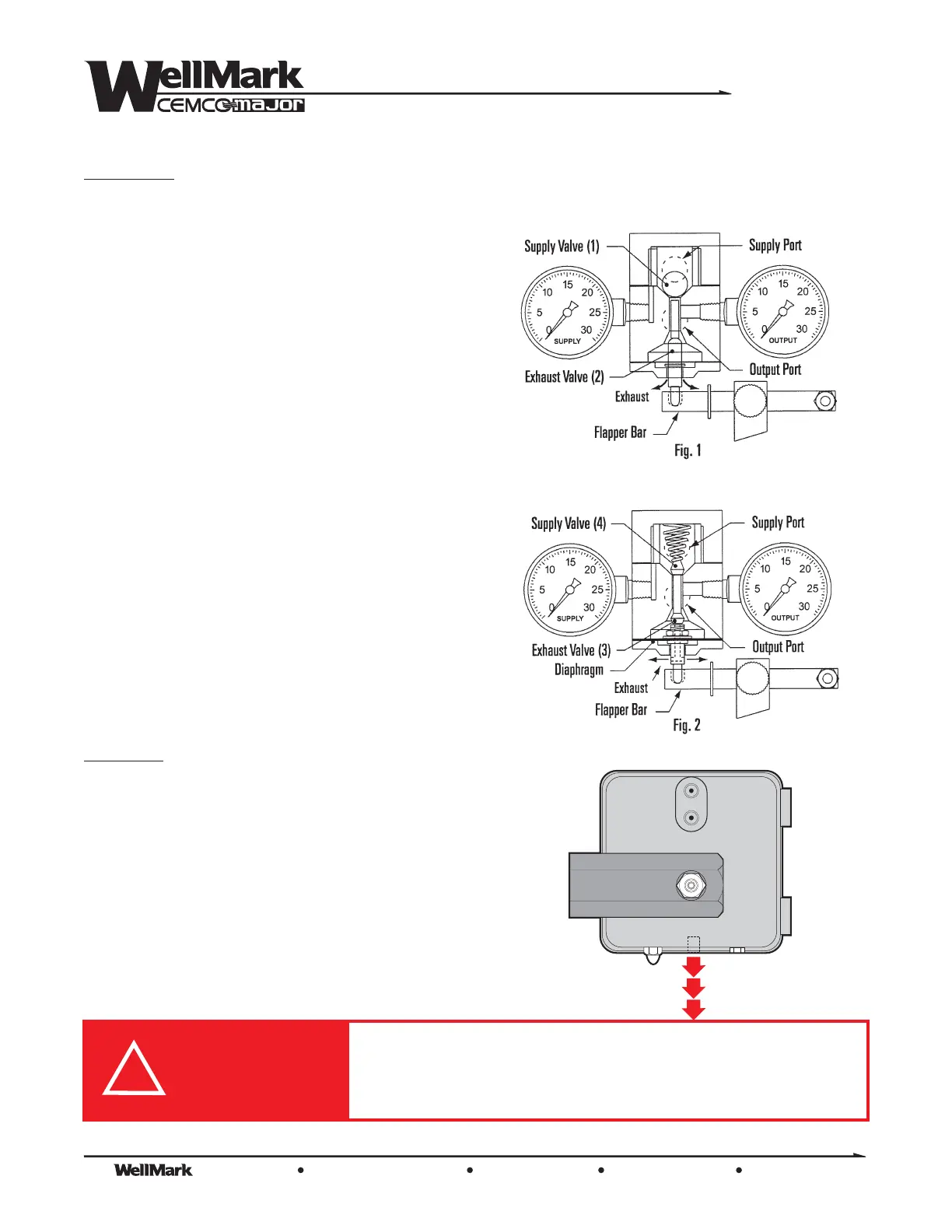

Throttle Pilot • No-Bleed Modulating FlowAction

Although the 2001NB Level Control is appropriately referred to

as , all pneumatic systems require that the

diaphragm operated motor valve exhausts or pressure off

the diaphragm once the valve has completed its actuation cycle.

This vented gas, along with the gas within the lines leading from

the control to the valve will vent back through the control. This

clear distinction, between gas and gas must be

made and understood. As with any or control, the

intent is to stop the unnecessary bleed of gas between valve

actuation cycles. The 2001NB Level Control will accomplish

this task. It will not however, nor will any other or

device stop the required venting of gas from the diaphragm and

lines once the valve has cycled.

The Snap-Acting Pilot is comprised of two inner valves. Valve (1)

admits system supply gas to output. Valve (2) controls system

exhaust from output. Valve (1), as shown in the closed position (Fig.

1), is held closed by force exerted from supply gas. When upward

Flapper Bar forces transferred to Valve (2) is sufficient enough to

overcome supply force, the ball snaps upward, allowing supply

pressure to communicate to output port, which operates the

diaphragm motor valve (not shown). The spherical end of Valve (2)

closes the exhaust port the instant the ball snaps upward and

remains seated against supply pressure until force on the valve

diminishes. As force is removed from Valve (2), causing it to unseat,

a simultaneous action occurs, causing Valve (1) to seat instantly,

closing the supply port to ouput and opening output to exhaust,

thereby allowing the diaphragm motor valve to reverse it’s action.

The Throttle Pilot utilizes a diaphragm, which creates a forced

balance Pilot (Fig. 2). Output pressure acts upon the diaphragm

causing it to push back at the same force being applied to the lower

seat. More force on the seat produces a proportionate increase in

Pilot pressure. When the Flapper Bar of the control exerts upward

force on the lower valve seat, it forces the lower seat closed against

valve body and opens the supply valve. Supply pressure enters the

system, increasing until the control and diaphragm motor valve (not

shown) pressure equals the Flapper Bar force and produces a forced

system balance. The control will stay in this position until a decrease

in the tank level reduces the force allowing exhaust, or an increase in

the level produces an action as described. System supply gas does

not flow while the Pilot is in balance.

“No-Bleed”

vents

“bleed” “vent”

no- low-bleed

no- low-bleed

The 2001NB Level Control has a sealed box which allows the user to pipe vent gas

away from the facility as needed. This is highly recommended if the control is to

be mounted inside an enclosure that might result in a dangerous build up of gas.

Failure to do so may result in damage to equipment, personal injury or death.

!

CAUTION!

SUPPLY

OUTPUT

Loading...

Loading...