ASSEMBLY AND ADJUSTMENTS

SETTING THE CUTTING SPEED (Fig. 5)

Your jig saw is equipped with a variable speed dial (Fig. 5 - 1) to set the

appropriate blade stroke rate for your operation. Speed setting 1 is the low-

est speed, and setting 6 is the highest speed (3300 RPM). To increase the

speed, turn the wheel forward to a higher number. To decrease speed, turn

the wheel backwards to a lower number.

The optimal cutting speed/stroke rate depends on the material being cut,

the type of blade being used, and the feed rate preferred by the operator.

Fig. 6

Fig. 7

Fig. 5

1

1

Fig. 4

As a general rule, use slower speeds for denser materials and use faster speeds for softer materials. To best deter-

mine the cutting speed, test on a scrap piece of identical material and adjust accordingly.

CAUTION: When the jigsaw is used at low speed settings for an extended length of time, the motor temperature

will rise due to slower speeds of the internal cooling fan. To prevent the motor from overheating, occasionally run

the tool at full speed for a few minutes to keep the motor running at high efficiency.

11

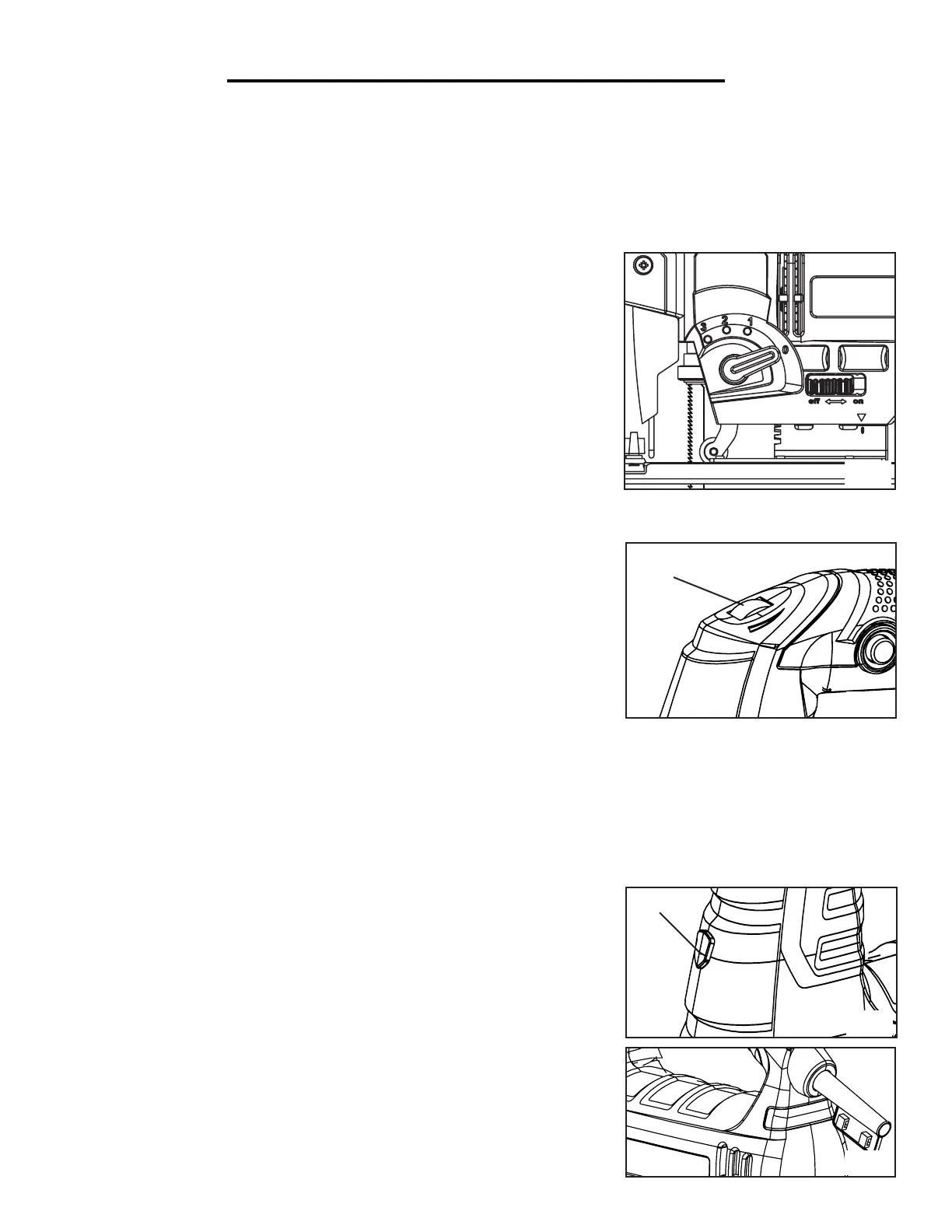

SETTING THE BLADE ORBITAL ACTION (Fig. 4)

The blade orbit selector lever controls the blade orbit travel distance. There are 4 settings, indicated on the side

housing (Fig. 4). At the 0 setting, the blade moves up and down in a straight line for smooth cutting. At the 3 setting,

the blade moves in an elliptical stroke for fast, aggressive cutting. Maximum cutting efficiency can be obtained by ad-

justing the blade orbit selector lever to suit the material being cut. This list below is guideline to help you determine

which setting to use for your application. To determine the best setting, test cuts in scrap materials first.

• Setting 0: Suits hard materials such as metals or thin sheet metals.

Use this setting for plunge cuts, as well as cutting curves and sharp edges.

• Setting 1: Suits medium-hard materials (hard wood, aluminum) and

thin workpieces. This setting can also be used for making round cuts and

sharp edge cuts.

• Setting 2: Suits soft materials such as wood and plastics where cleaner

cutting or delicate scrolling work is performed.

• Setting 3: Suits soft materials such as wood and plastics. Use this setting

for faster and more aggressive cutting.

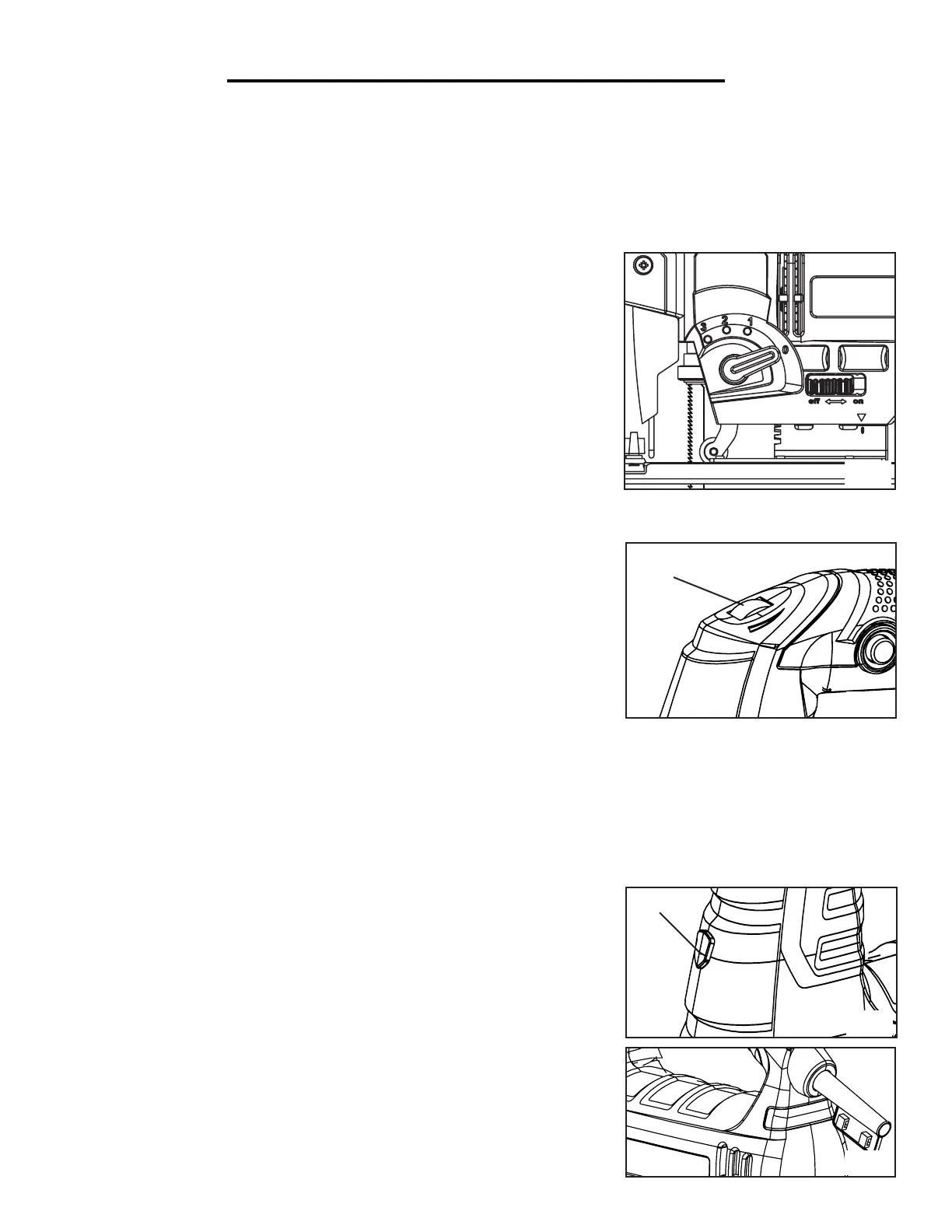

TURNING ON THE LASER AND LED LIGHT (Fig. 6)

Your tool is equipped with a laser and LED light. Use the button on the

front of the tool (Fig. 6 - 1) to control this feature.

•Press 1: Laser (see page 7 for laser safety rules)

•Press 2: Light

•Press 3: Laser and light

•Press 4: OFF

POWER INDICATION LIGHT (Fig. 7)

The power indication light turns green when the tool is connected to the

power. If the light turns red, that mean that means the tool has diagnosed a

problem. Disconnect the tool and contact customer service for assistance.

Loading...

Loading...