13

OPERATION

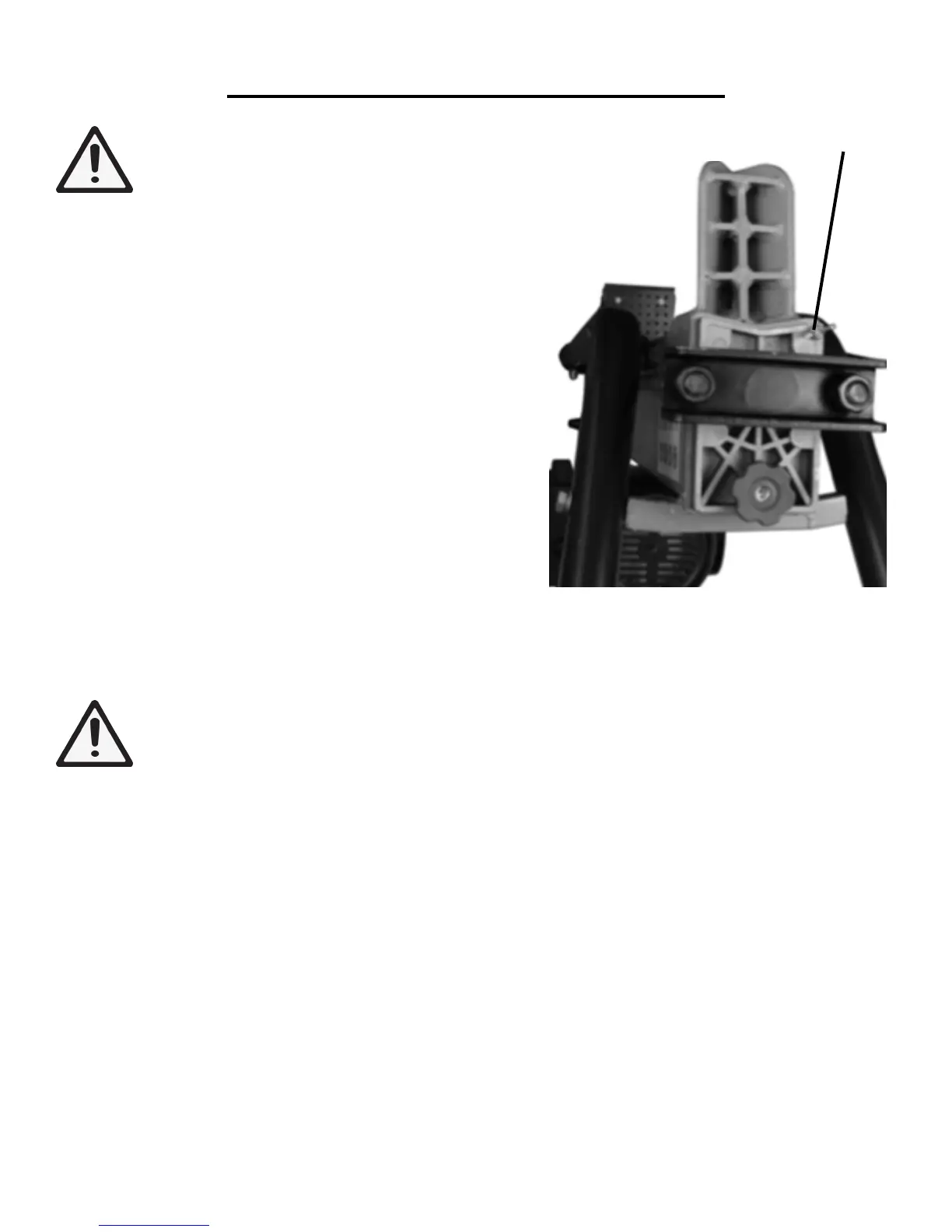

1

WARNING: Always loosen the bleed

screw prior to operation. This will remove

any air trapped in the hydraulic system.

Failure to release air from the hydraulic system may

damage the hydraulic seals, permanently damaging the

Log Splitter.

To loosen the bleed screw:

1. Turn the bleed screw (1) counterclockwise one or

two turns to allow air to be released from the hydraulic

system.

NOTE: While the Log Splitter is in use, there should

be a detectable flow of air through the bleed screw.

2. Close the bleed screw after operation.

NOTE: Check the bleed screw and make sure it is

closed before and during transporting the log splitter to

and from the jobsite and storage area. Hydraulic fluid

may leak through the bleed screw opening if the bleed

screw is not fully tightened.

WARNING: Never try to split logs larger than the rated capacity of the tool. Attempting to do so

could result in personal injury and damage to the tool.

To place and split a log on the Log Splitter:

1. Make sure the log is prepared and suitable for use with this machine. There should be no nails or foreign ob-

jects in the log, the ends should be cut square, any branches should be cut flush with the trunk, and the log should

be no longer than 21 inches with a diameter less than or equal to 10 inches.

2. Ensure the equipment is in safe working condition. Operate the unit without loading to make sure it is working

normally. Check all nuts, bolts and hydraulic fittings are tight. Check the switch, power cable and plug for damage

to avoid electric shock.

3. Plug in the power cable. NEVER use an extension cord longer than 25 feet. Minimum cord gauge must be 16.

The power supply for this log splitter must have a protection device (circuit breaker) for over or under voltage.

4. Place a log on the beam against the ram. Make sure that the log is securely on the beam and up against the ram.

Logs should be cut with square ends and to a maximum length of 20.5 inch in advance. Always use extra care

when splitting logs with unsquare ends.

Loading...

Loading...