Do you have a question about the Wenglor P1KH Series and is the answer not in the manual?

Provides essential information about the document's applicability and usage guidelines.

Defines symbols and attention-getting words used for safety precautions and warnings.

Outlines the manufacturer's liability exclusion conditions based on product usage and compliance.

States the copyright protection and usage restrictions for the document's content.

Details the functional principle and industry sectors where the product is designed for use.

Warns against using the product as a safety component or in explosive atmospheres.

Specifies the required training and qualifications for personnel operating the product.

Prohibits product modification, warning of risks to safety and warranty.

Lists general safety measures, including keeping instructions handy and protecting the sensor.

Provides information on laser classification and applicable safety standards for the sensor.

Lists product certifications and protection class ratings for compliance and environmental resistance.

Specifies optical characteristics such as service life, ambient light, and hysteresis.

Details electrical parameters including supply voltage, output characteristics, and protection features.

Outlines mechanical specifications like setting method, housing material, and degree of protection.

Presents the spot diameter values for different ranges of the sensor product.

Lists switching frequency and response times based on operating mode and output configuration.

Recommends suitable mounting and connection technologies for the sensor.

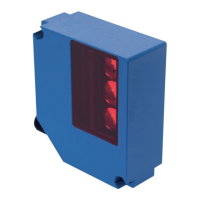

Shows dimensional drawings and key features of the sensor models.

Describes the components of the sensor's control panel and their functions.

Lists the items included in the product's delivery package.

Instructs on inspecting the product for damage upon receipt and handling transit damage.

Provides guidelines for proper storage conditions to prevent damage and ensure product integrity.

Covers essential steps for installing the sensor, including protection and secure mounting.

Details the wiring diagram and pin assignments for connecting the sensor.

Explains how to interpret diagnostic indicators and resolve common error conditions.

Describes the procedure for teaching the switching distance for the first output.

Details the process for teaching the switching distance for the second output.

Explains the sensor's teach mode functionality for setting switching distances via IO-Link.

Describes how to configure the I/O2 pin as an input or output and its functions.

Lists advanced functions and parameters configurable through the IO-Link interface.

Provides a glossary of abbreviations used throughout the operating instructions.

Lists revisions and changes made to the operating instructions over different versions.

Directs users to find the EU Declaration of Conformity document on the manufacturer's website.

This document describes the P1KHxxx series of reflex sensors with background suppression, featuring high-end performance and teach-in functionality, manufactured by wenglor sensoric elektronische Geräte GmbH.

The P1KHxxx reflex sensors operate on the principle of angular measurement, analyzing light reflected from objects. This design minimizes the influence of an object's color, shape, and surface characteristics on the detection range, allowing for reliable detection of even dark objects against a bright background. The sensor switches its output when an object enters the selected range. These sensors are designed for a wide array of industrial applications, including special machinery manufacturing, heavy machinery manufacturing, logistics, automotive, food, packaging, pharmaceuticals, plastics, woodworking, consumer goods, paper, electronics, glass, steel, aviation, chemicals, alternative energy, and raw materials extraction.

The sensors are not safety components according to 2006/42/EC (Machinery Directive) and are not suitable for use in potentially explosive atmospheres. They should only be used with wenglor-supplied or approved accessories and products.

Optical Data:

Electrical Data:

Mechanical Data:

Specific Models (P1KH series):

Output Functions:

Switching Frequency / Response Time:

Installation:

Control Panel:

Teach-in Mode: The switching distance can be taught in for both outputs using the teach-in key on the sensor.

Pin Function, I/O2 (Configurable):

Settings via IO-Link: Further functions and settings can be configured via the IO-Link interface, including:

Diagnostics (Contamination Warning - blinking LED):

Proper Disposal:

| Brand | Wenglor |

|---|---|

| Model | P1KH Series |

| Category | Accessories |

| Language | English |