INJECTORS

Remove

and

refit

19.60.01

Service tools: 18G 284, 18G

284

P

Removing

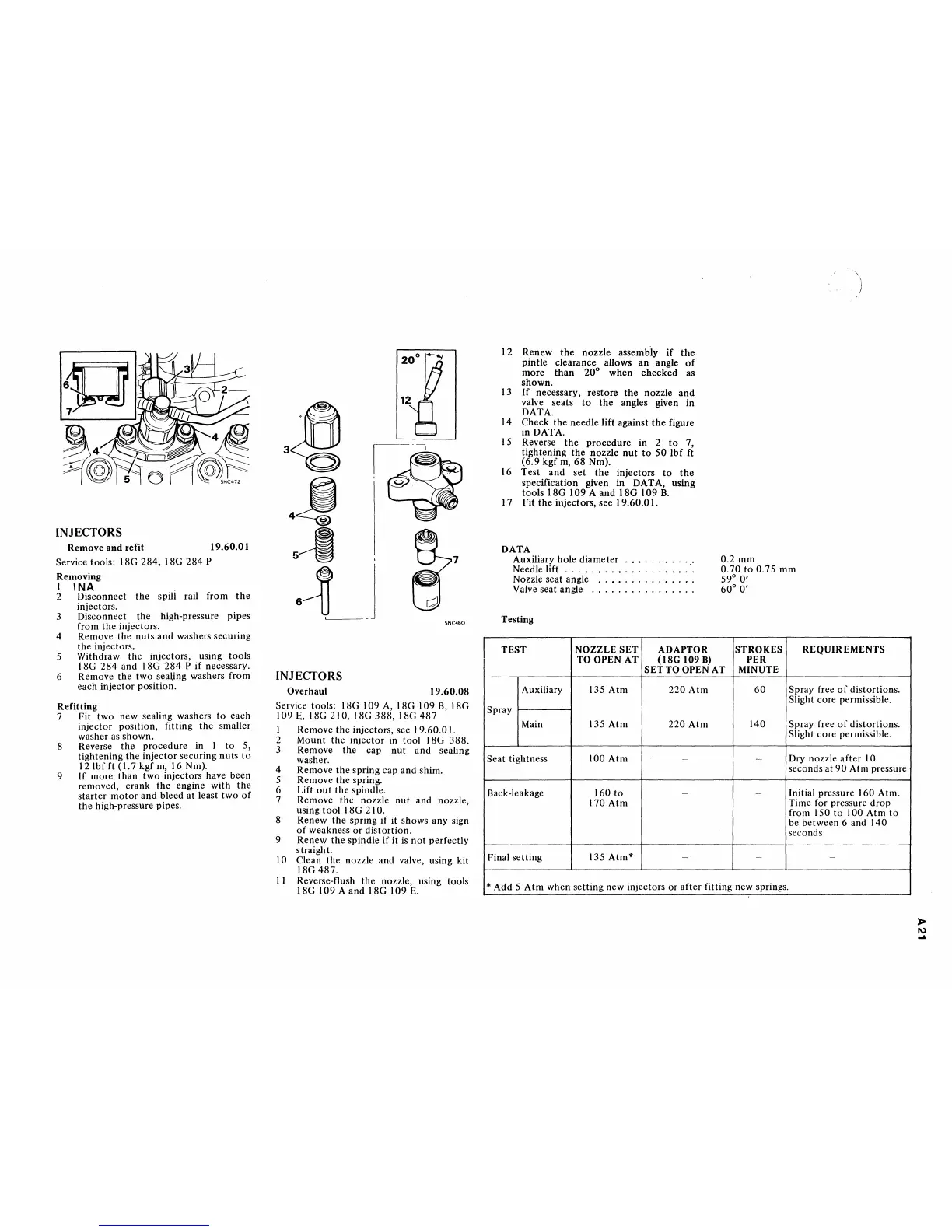

I

INA

.

2 Disconnect

the

spill rail from

the

injectors.

3 Disconnect

the

high-pressure pipes

from

the

injectors.

4 Remove

the

nuts

and

washers securing

the

injectors.

5 Withdraw

the

injectors, using tools

18G

284

and

18G

284

P

if

necessary.

6 Remove

the

two

sealing washers from

each injector position.

Refitting

7 Fit

two

new sealing washers

to

each

injector position, fitting

the

smaller

washer

as

shown.

8 Reverse

the

procedure

in I

to

5,

tightening

the

injector securing

nuts

to

121bfft

(1.7

kgf

m,

16 Nm).

9 If

more

than

two

injectors have been

removed,

crank

the

engine with

the

starter

motor

and

bleed at least

two

of

the

high-pressure pipes.

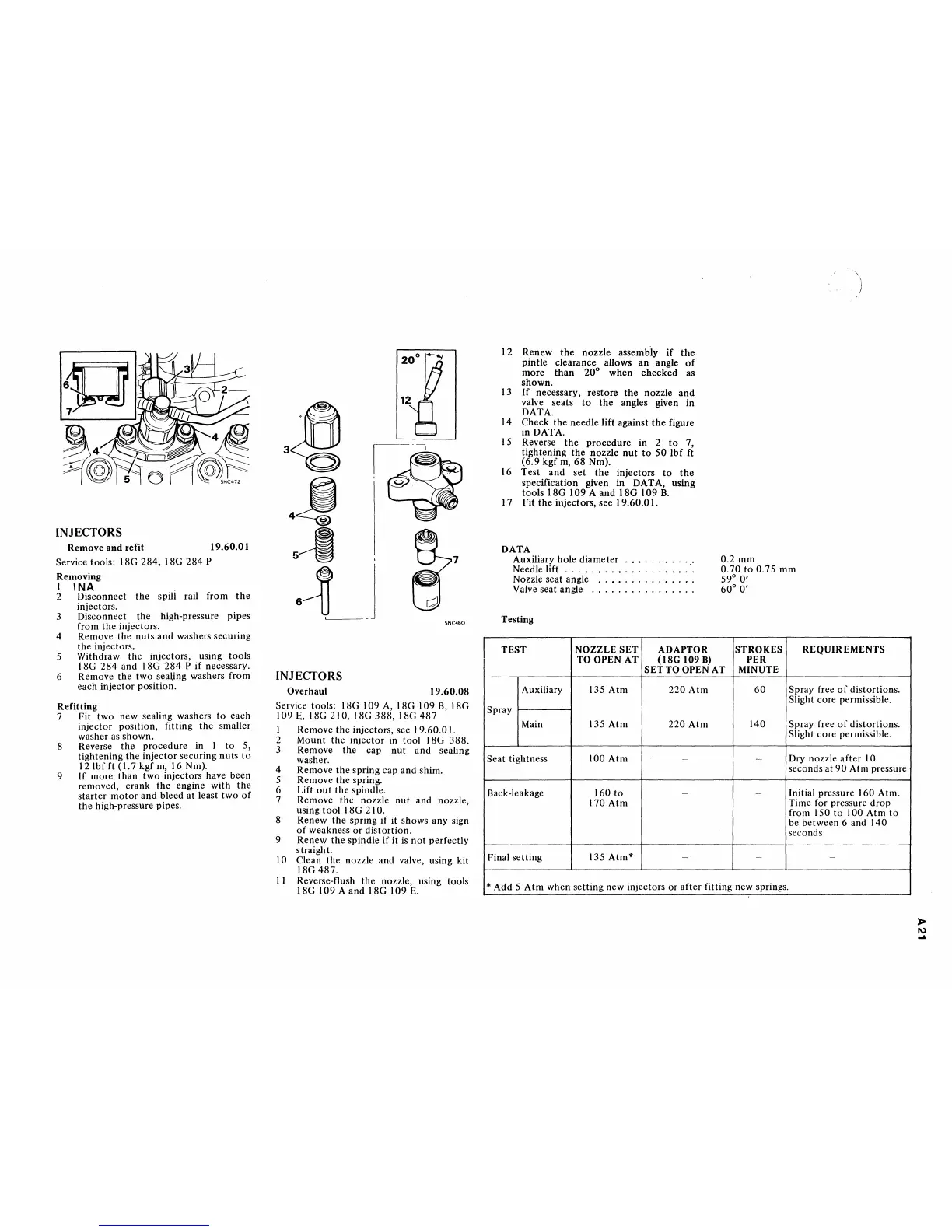

20°

fiq

~

I

cu.

4~

5~

7

6~1

5NC480

INJECTORS

Overhaul

19.60.08

Service tools: 18G 109

A,

18G 109

B,

18G

1091::;,

18G 210, 18G

388,

18G

487

I Remove

the

injectors, see

19.60.0

I.

2 Mount

the

injector in

tool

18G

388.

3 Remove

the

cap

nut

and

sealing

washer.

4 Remove

the

spring cap

and

shim.

5 Remove

the

spring.

6 Lift

out

the

spindle.

7 Remove

the

nozzle

nut

and nozzle,

using

tool

18G 210.

8 Renew

the

spring if it shows any sign

of

weakness

or

distortion.

9 Renew

the

spindle if it

is

not

perfectly

straight.

10 Clean

the

nozzle and valve, using kit

18G

487.

II

Reverse-flush

the

nozzle, using tools

18G

109

A

and

18G 109

E.

12 Renew

the

nozzle assembly

if

the

pintle clearance allows

an

angle

of

more

than

20°

when

checked

as

shown.

13

If

necessary, restore

the

nozzle

and

valve seats

to

the

angles given in

DATA.

14 Check

the

needle lift against

the

figure

in DATA.

I 5 Reverse

the

procedure

in 2

to

7,

tightening the nozzle

nut

to

50

Ibf

ft

(6.9

kgf

m,

68

Nm).

16 Test

and

set

the

injectors

to

the

specification given in DATA, using

tools

18G

109 A

and

18G

109

B.

17 Fit

the

injectors, see

19.60.0

I.

DATA

Auxiliary hole

diameter

..•........

Needle lift

...•.•..•..........

'.

Nozzle seat angle

..............

.

Valve seat angie

...............

.

Testing

TEST

NOZZLE

SET

ADAPTOR

TO OPEN

AT

(18G

109

B)

0.2 mm

0.70

to

0.75

mm

59°

0'

60°

0'

STROKES

PER

REQUIREMENTS

SET

TO OPEN AT

MINUTE

Auxiliary 135 Atm

220

Atm

60

Spray free

of

distortions.

Slight core permissible.

Spray

Main

135

Atm

220

Atm

140 Spray free

of

distortions.

Slight

core

permissible.

Seat tightness 100

Atm

- -

Dry nozzle

after

10

seconds at

90

Atm pressure·

Back-leakage 160

to

-

-

Initial pressure 160 Atm.

170

Atm

Time for pressure drop

from 150

to

100 Atm

to

!

be between 6 and 140

seconds

Final setting 135

Atm*

- - -

* Add 5

Atm

when

setting

new injectors

or

after

fitting new springs.

»

III

...

Loading...

Loading...