ENGINE

DISASSEMBLY

8. With

the

hoses disconnected,

remove

the

thermostat

housing

and

housing gasket, leaving the temperature

sender in place.

9. Remove

the

coolant circulating

pump.

Refer to

COOLANTPUMPASSEMBL~

10. Remove

the

air intake silencer

and

the

intake

manifold.

11.

Remove

the

oil filter

and

the

mounting

bracket

from

the

engine block.

12.

Unbolt

the

elbows

and

remove

the

exhaust

manifold

in

its entirety.

Remove the exhaust manifold/expansion

tank

in its

entirety. Disassemble separately,

clean

aU

surfaces, install

new gaskets when assembling. Use good quality gasket

cement.

NOTE:

Early

versions

were

an

assembly,

later versions

are

a

cast

unit.

(Cast units

are

only available

today).

14. Remove

the

engine

mounted

fuel filter with electric

fuel

lift

pump

and

related

lines.

NOTE:

The

positions

of

the

sealing washers that attach fuel lines

to

the

fuel

filter;

the

injection pump and the electric fuel

pump.

15. Remove

the

fuel injection

pump.

Disconnect the fuel injection pipes and fuel leak-off pipe

from the fuel injection pump and nozzles.

NOTE:

Put plugs or caps

on

the openings

of

the

injection pump

and

nozzle

connectors.

Golf tees work well

as

plugs.

16. Remove

the

fuel injection nozzles. Loosen the fuel

injection nozzles with a wrench. Remove the nozzles and

gaskets from the cylinder head.

·

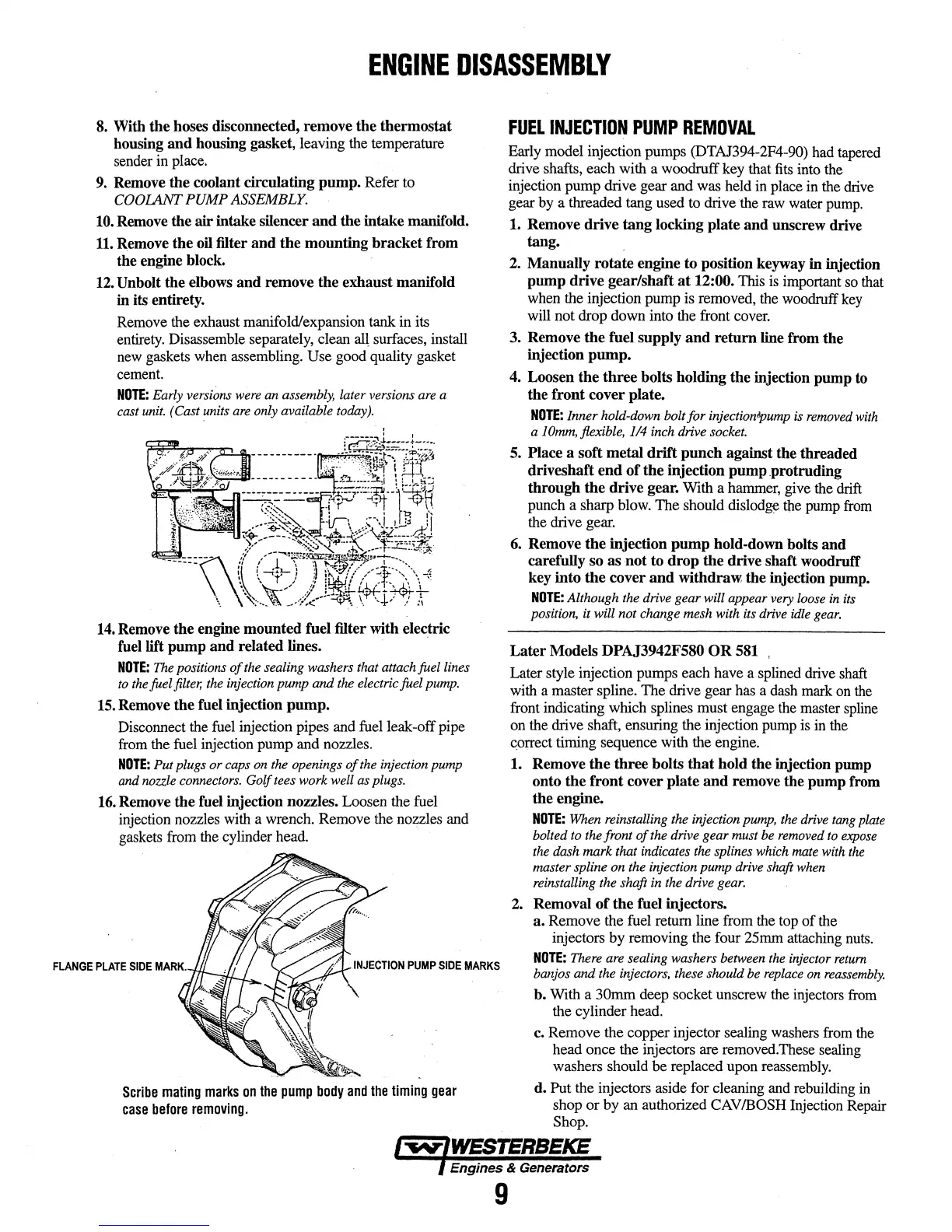

Scribe

mating

marks

on

the

pump

body

and

the

timing

gear

case

before

removing.

FUEL

INJECTION

PUMP

REMOVAL

Early model injection pumps (DTAJ394-2F4-90) had tapered

drive shafts, each with a woodruff key that

fits

into the

injection

pump

drive gear and was held in place in the drive

gear by a threaded tang used to drive the raw water pump.

1. Remove

drive

tang

locking

plate

and

unscrew drive

tang.

2.

Manually

rotate

engine to position keyway

in

injection

pump

drive

gear/shaft

at

12:00. This is important so that

when the injection pump is removed, the woodruff key

will not drop down into the front cover.

3. Remove

the

fuel supply

and

return line from

the

injection

pump.

4. Loosen

the

three

bolts holding

the

injection

pump

to

the

front

cover

plate.

NOTE:

Inner hold-down bolt for

injection~ump

is

removed

with

a

JOmm,

flexible,

114

inch drive

socket.

5. Place a

soft

metal

drift

punch

against

the

threaded

driveshaft

end

of

the

injection

pump

_protruding

through

the

drive

gear. With a hammer, give the drift

punch a sharp blow. The should

dislod~

tbe pump from

the drive gear.

6. Remove

the

injection

pump

hold-down bolts

and

carefully

so

as

not

to

drop

the

drive

shaft

woodruff

key

into

the

cover

and

withdraw.

the

injection pump.

NOTE:

Although

the

drive gear will appear

very

loose

in

its

position, it will not change mesh with

its

drive

idle

gear.

Later

Models DPAJ3942F580

OR

581 ,

Later style injection pumps each have a splined drive shaft

with a master spline. The drive gear has a dash mark on the

front indicating which splines must engage the master spline

on the drive shaft, ensuring the injection pump is in the

~orrect

timing sequence with the engine.

1. Remove

the

three

bolts

that

hold

the

injection

pump

onto

the

front

cover

plate

and

remove

the

pump

from

the

engine.

NOTE:

When

reinstalling the injection

pump,

the

drive

tang

plate

bolted

to

the

front

of

the drive gear must

be

removed

to

expose

the

dash mark that indicates

the

splines which

mate

with

the

master spline on the injection pump drive shaft

when

reinstalling the shaft

in

the drive

gear.

2. Removal

of

the

fuel injectors.

a.

Remove the fuel return line from the top

of

the

injectors

by

removing the four

2Smm

attaching nuts.

NOTE:

There

are

sealing washers between

the

injector

return

banjos and the injectors, these should

be

replace

on

reassembly.

b.

With a 30mm deep socket unscrew the injectors from

the cylinder head.

c.

Remove the copper injector sealing washers from the

head once the injectors are removed.These sealing

washers should be replaced upon reassembly.

d. Put the injectors aside for cleaning and rebuilding

in

shop

or

by an authorized

CAV

/BOSH Injection Repair

Shop.

~

WESTERBEKE

9

Loading...

Loading...