Sealed System Repair

R600A Sealed System

n

2-3

Sealed System Access Procedure

¾ First, Verify Failure

¾ REQUIRED to Acvate the Combusble Gas Detector before

any work is started. Place the Detector at the lowest point

of the work area.

¾ Ensure Pre-Work Checks in Secon 2.2 are Completed.

¾ If you are working on a Sealed system with a Three Way

Valve.

¾ Position 3-Way Valve to Home Position.

¾ Enter diagnostic mode.

¾ Initiate Step To open the Three Way Valve (refer to tech

sheet) and wait 1 minute.

¾ Unplug the refrigerator.

¾ Remove the Machine Compartment Cover.

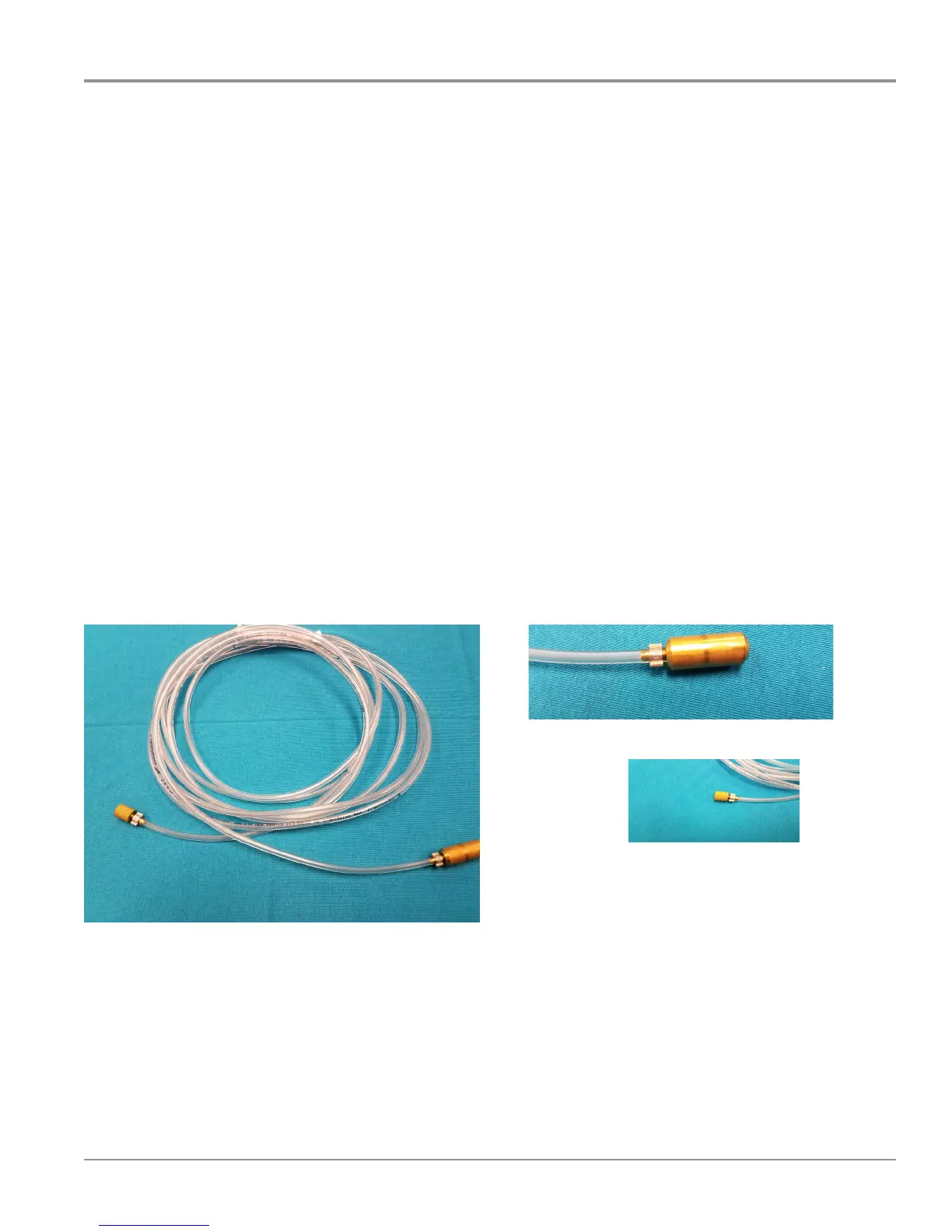

¾ Attach quick disconnect fittings to High Side Fitting.

¾ Attach to Schrader Valve if present.

¾ If Schrader Valve is not present, use piercing pliers to access

High Side of the sealed system. Attach quick disconnect

fitting to the piercing pliers. If the compressor is non

functional, connect a second piercing pliers to the

suction process tube.

R600a Refrigerant

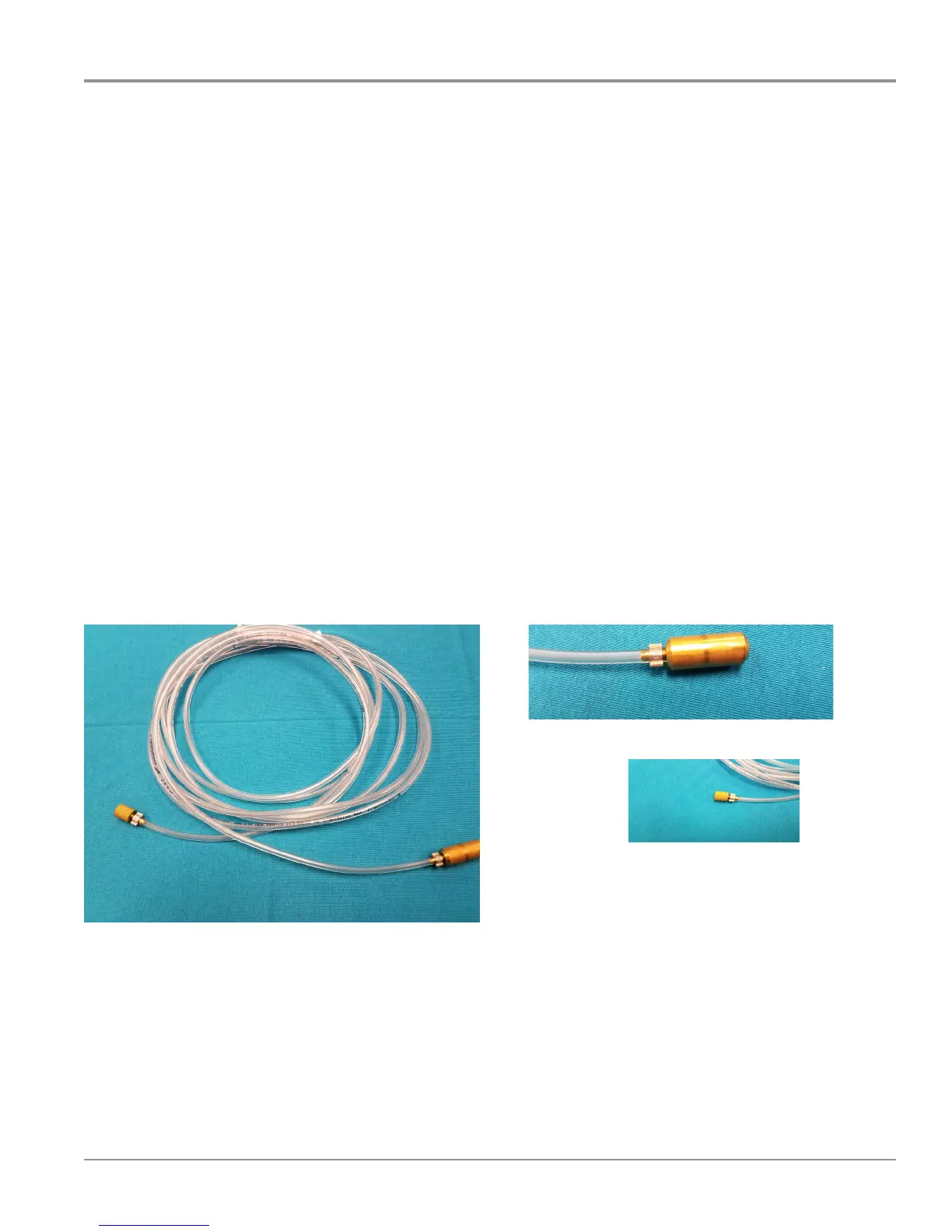

• The LOKBOX Charging Facility is equipped with a 20’ PVC

Recovery Hose. This length should be sucient to reach an

outdoor locaon in most instances.

• Unlike tradional CFC’s and HCFC’s, the EPA allows venng

of R600a refrigerant to the outside atmosphere.

• Venng is the preferred method of removing refrigerant

from a sealed system.

Venting Process

¾ When (all requirements are met, venng allows the refrigerant

to be safely dispersed in the natural environment, removing

the hazard of concentrang and transporng ammable

immediately.

¾ When venng, it expands to atmospheric pressure. Venng

mes will vary for many reasons, including but not limited

to, the size of charge, atmospheric pressure, whether the

compressor is running. Connue venng the appliance for an

addional 10 minutes aer the pressure coming out ends.

¾ ATTENTION: Do not vent R600a refrigerant indoors.

¾ ATTENTION: Ensure there is no source of ignion near the

discharge hose.

R600a vent locations must meet the following criteria:

• R600a must be discharged to the outside environment.

• Discharge locaon must not be a public area or area where

people are unaware of the procedure taking place.

• There must be no sources of ignion near the hose discharge.

• Ensure that there is no posibilty for refrigerant to be blown back

into any buildings, or to a locaon below ground level.

Sealed System Refrigerant Venting Procedure

(Preferred)

¾ Route the weighted end of the 20’ PVC Recovery Hose to an

outdoor locaon.

¾ Connect the opposite end on the 20’ Recovery Hose to the

quick disconnect ng on the High Side piercing pliers to begin

venng.

¾ If the compressor is funconal, run the compressor to speed the

venng process.

¾ Monitor the Recovery Hose and discharge point.

¾ Ensure the hose remains kink free.

¾ Ensure the Refrigerant Venng Requirements are met

connually throughout the venng process.

¾ Observe the mirage eect at the hose discharge as the R600a

refrigerant exits. Note when the mirage eect stops.

¾ A mirage is a naturally occurring opcal phenomenon in which

light rays are bent to produce a displaced image of distant

objects or the sky.

¾ Hitting the compressor with a Rubber Mallet at this time will

remove any trapped R600a from the oil.

¾ Continue Venting for an additional 10 minutes to ensure

system is fully vented. After the sealed system is fully vented,

disconnect the Recovery Hose from the quick disconnect ng.

Loading...

Loading...