19

h

Remove the plug from the socket before carrying out any adjustment, servicing or maintenance.

There are no user serviceable parts in your power tool. Never use water or chemical cleaners to clean your power tool.

Wipe clean with a dry cloth. Always store your power tool in a dry place. Keep the motor ventilation slots clean. Keep

all working controls free of dust. Occasionally you may see sparks through the ventilation slots. This is normal and will

not damage your power tool. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualied persons in order to avoid a hazard.

MAINTENANCE

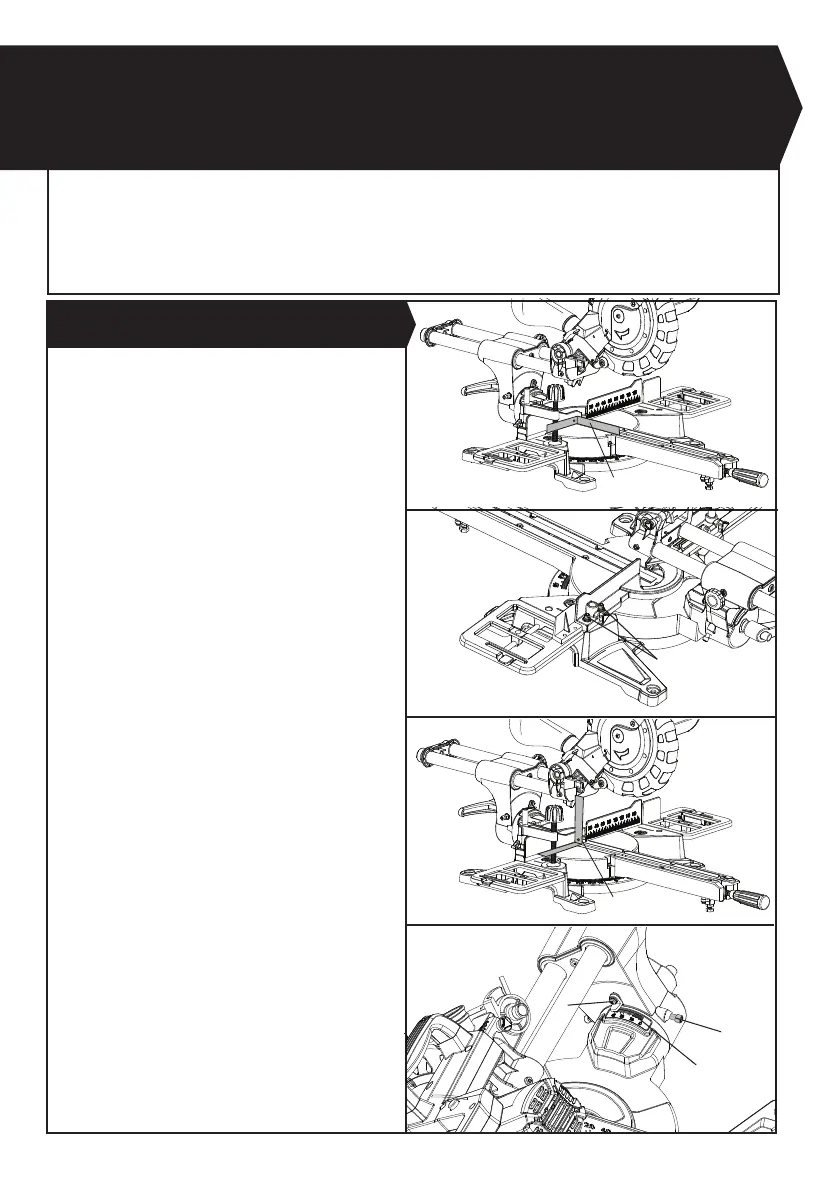

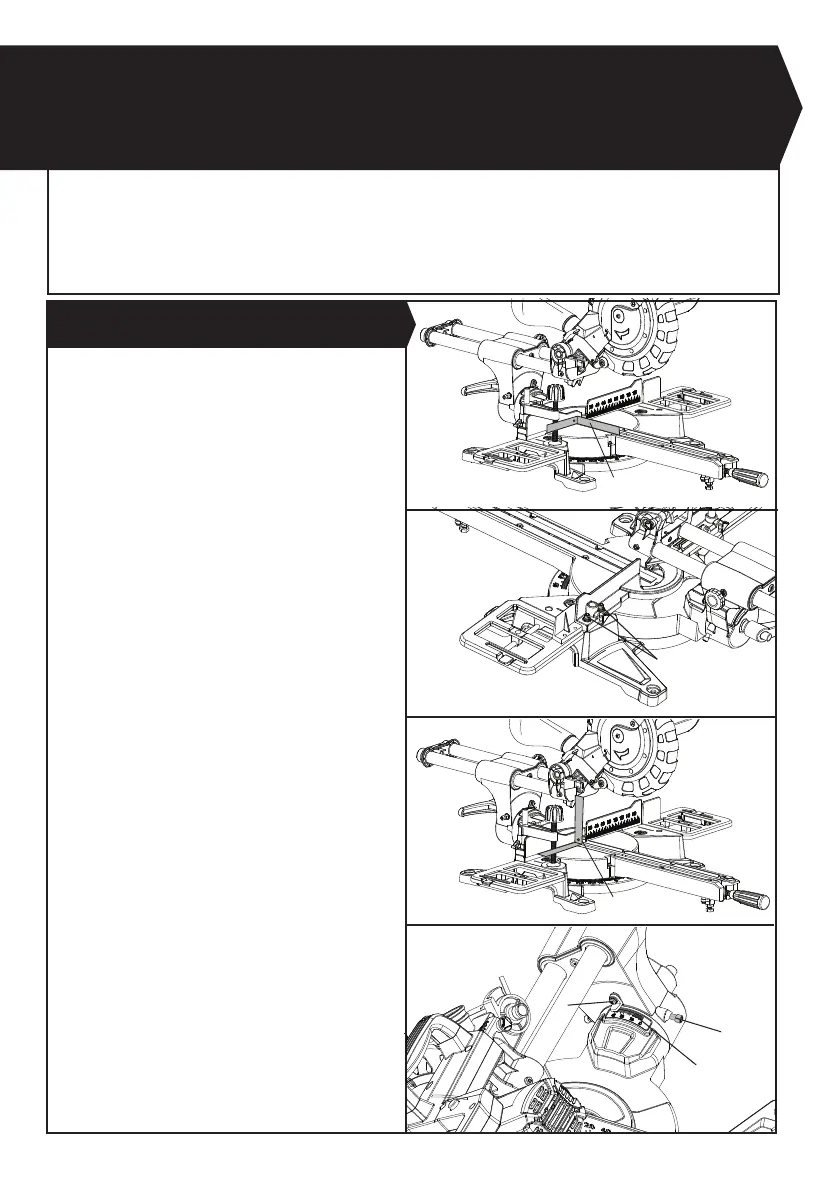

While the machine has been factory set, it is advisable

that the 0

o

setting of the rotary table and the 90

o

perpendicular setting of the tilt be checked, as these

positions may have moved in transit.

To conrm the 0

o

rotating mitre table setting, set the

rotating mitre table at 0

o

and tighten the mitre table lock

latch. Check that the angle between the straight guide

and the blade is 90° using a tri-square (h) (not supplied)

as shown in Fig. S1. If the angle requires adjustment,

loosen the locking bolts (i) for straight guide, and align

the fence against the tri-square.

Re-tighten the locking bolts (i) for straight guide.

Similarly, check that the angle of the blade to the face of

the rotary table is 90°. If necessary, adjust the tilt angle

of the saw head at the 90

o

position: loosen the bevel

lock lever and adjust the 0° bevel adjustment screw (j)

to bring the saw blade into alignment with the square.

Loosen the head screw (k) holding the pointer of the

bevel scale and adjust the position of the pointer so that

it accurately indicates zero on the scale. Retighten the

head screw (k). Retighten the bevel lock lever and the 0°

bevel adjustment screw (j).

1. PRECISION SETTING OF ANGLES(SEE FIG. S1-S4)

h

i

j

k

28

Fig. P

Fig. Q

Fig. S4

Fig. S1

Fig. S2

Fig. S3

Loading...

Loading...