INSTRUCTION MANUAL

NI-221WE

Rev. 5 12/16

3 of 9

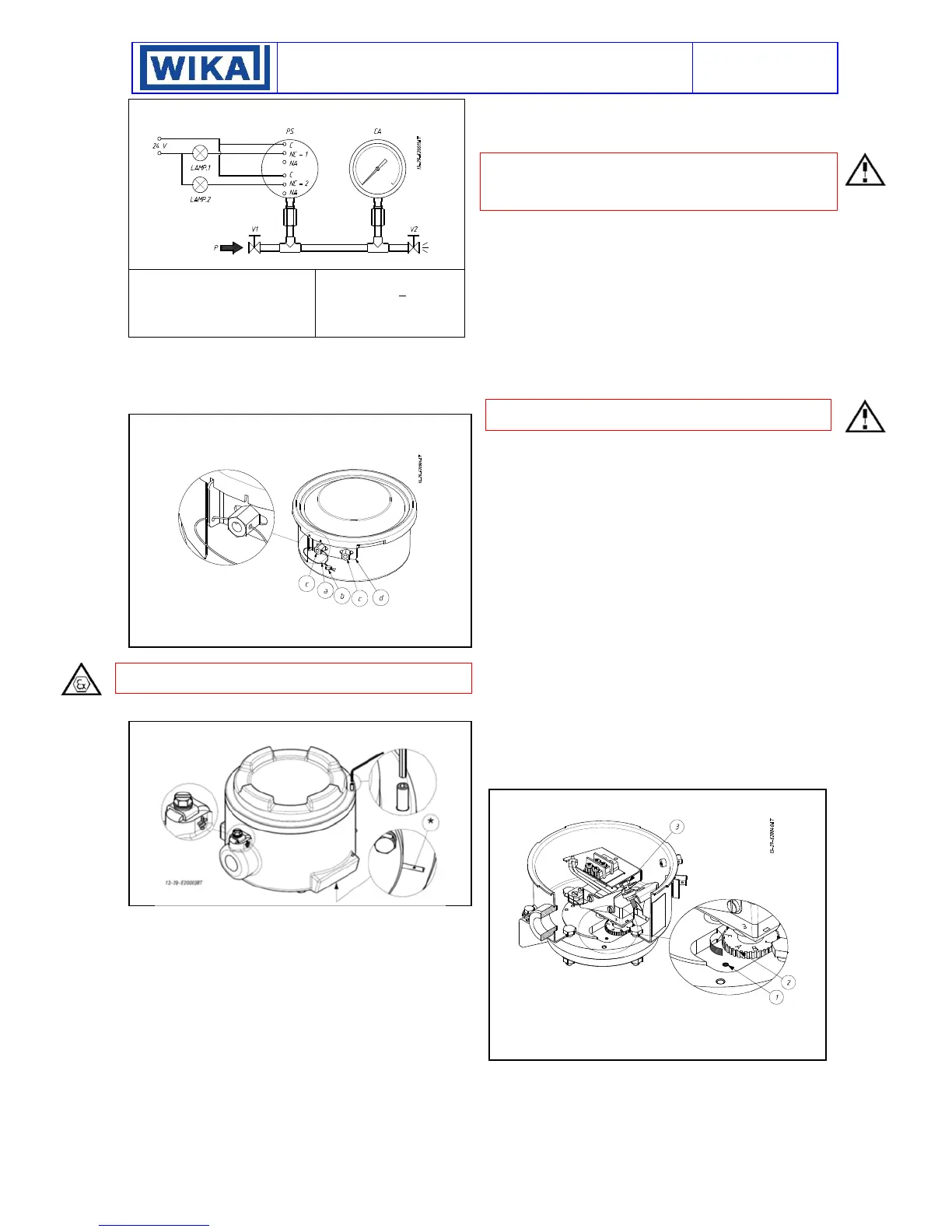

Fig. 3 - Calibration circuit

PS - Pressure switch

CA - Test gauge

V1 - Inlet valve

V2 - Discharge valve

P - Pressure source

Test fluid:

air for P < 10 bar

water for P > 10 bar

6.1

PRELIMINARY OPERATIONS

6.1.1

Weatherproof pressure switches (Model MW)

Remove the blocking device fixed to the side of the instrument

case (Fig. 4).Remove the cover by rotating it in an anticlockwise

direction.

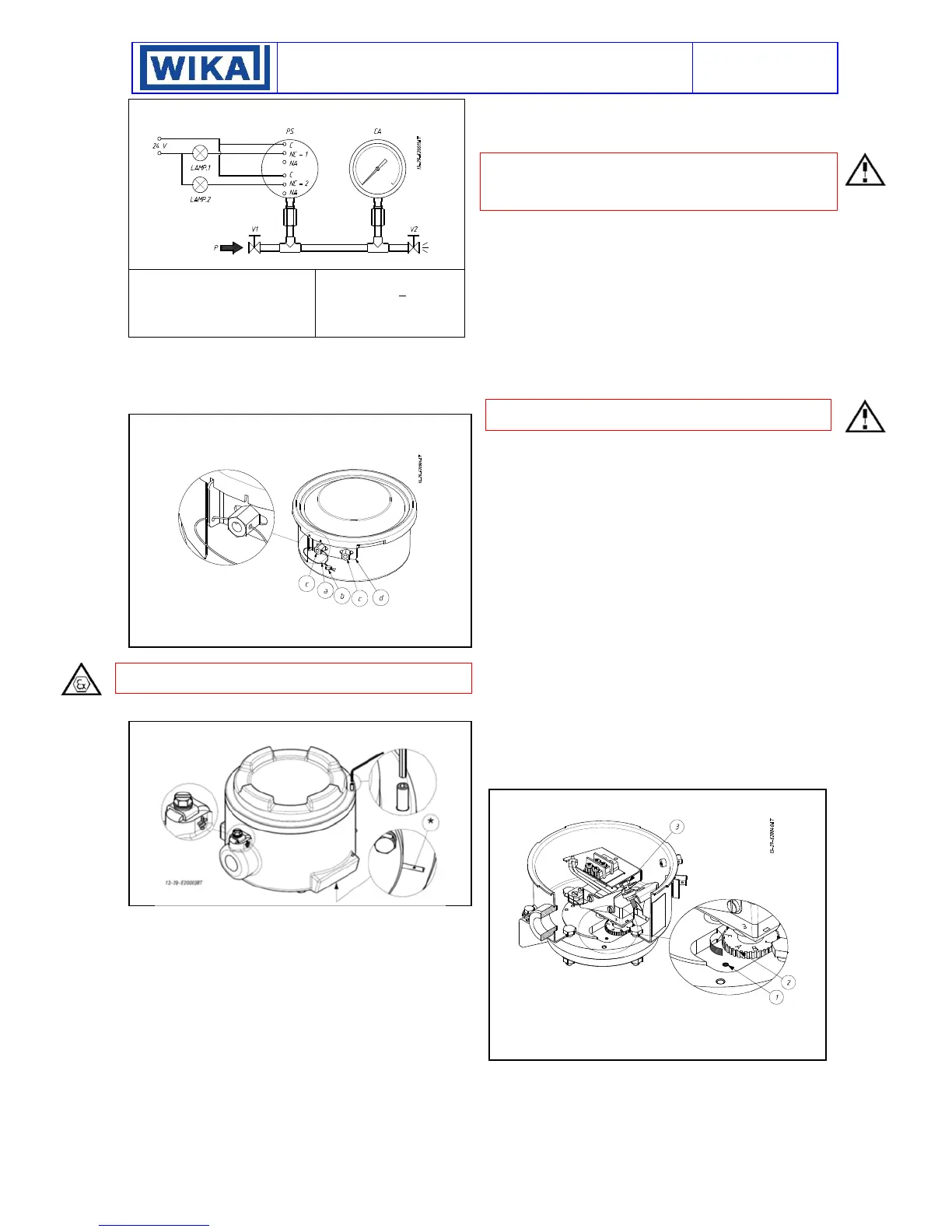

Fig. 4 - Weatherproof pressure switch blocking device

a - Plumbing wire

b - Plumbing

c - Nut

d - Blocking bracket

6.1.2

Flameproof pressure switches (Model MA)

CAUTION: do not open the cover of pressure switches when en-

ergized, in explosive atmospheres.

Loosen the locking headless screw situated on the cover using a

1,5 hexagonal key then unscrew the cover (fig.5).

Fig. 5 - Flameproof pressure switch blocking device

6.2

CALIBRATION CIRCUIT AND OPERATIONS

Prepare the calibration circuit as indicated in Fig.3.

The warning lamps should be connected to contact 1 or 2 in the

NO or NC position according to the required contact action.

Connection of C and NO terminals

• If the circuit is open at the working pressure, the switch closes

the circuit as the pressure increases when the desired value is

reached.

• If the circuit is closed at the working pressure, the switch opens

the circuit as the pressure decreases when the desired value is

reached.

Connection of C and NC terminals

• If the circuit is closed at the working pressure, the switch opens

the circuit as the pressure increases when the desired value is

reached.

• If the circuit is open at the working pressure, the switch closes

the circuit as the pressure decreases when the desired value is

reached.

The pressure switch must be mounted in the normal installation

position, i.e. with the pressure connection pointing downwards.

Avoid forcing the elastic support of the microswitch by hand or with

tools. This could affect the instrument functioning.

CAUTION: if the switch is of the kind with adjustable dead band

(letter R in the contact codes) before proceeding with the following

operations it is necessary to proceed with the adjustment of the

dead band.

Increase the pressure in the circuit up to the desired set point value

for the first microswitch. Use a wide bladed screwdriver, as indi-

cated on the label, turn the screw until the relative lamp turns on

(or turns off).

- If the instrument is equipped with only one contact the calibration

is complete.

- If it is equipped with two contacts continue in the following man-

ner. Vary the pressure until the desired set point value for the sec-

ond microswitch is reached. Act on the adjustment screw of the

second contact.

Repeat calibrating operations on the first contact, then on the sec-

ond contact, until the required set point accuracy is obtained. This

is necessary due to the reciprocal influence which the micro-

switches have on the sensitive element of the instrument.

CAUTION: if the two set point are different they must be different

for much of 5% of the adjustable span.

6.3

CALIBRATION OF INSTRUMENT WITH SENSING

ELEMENT H AND G

The pressure switches equipped with sensor H and G, are

instruments with a piston sensing element. To perform an high

accuracy calibration, due to the sensing element, it is necessary to

adjust the set point by varying the pressure from the normal

working pressure of operation to the set point.

6.4

CHECK OF SET POINT

Generate the normal working pressure and wait the pressure sta-

bilisation. Vary the pressure into the circuit and record the set point

value. Write the set point values on the adhesive label.

Note: the repeatability should be checked verifying for three times

the set point (Pi) starting always from the same pressure value

(Pw). The pressure cycle should be slowly to give the possibility to

record the set point with accuracy.

6.5

ADJUSTMENT OF DEAD BAND (LETTER R ON THE

MODEL CODE)

The dead band can be adjusted only on the instrument is equipped

with a microswitch, which allows adjusting (Letter R on the model

code). Adjustment may be obtained by rotating the wheel placed

on the microswitch (Fig. 6).

In order to carry out this operation it is advisable to insert thumb

and forefinger of the left hand in the instrument. The instrument is

normally delivered adjusted on the minimum value of its range

(factory calibration).

Fig. 6 – Adjustment of dead band

Mark

Dead band adjustment wheel

Set point adjustment screw

Loading...

Loading...