INSTRUCTION MANUAL

NI-221WE

Rev. 5 12/16

7 of 9

15

TROUBLESHOOTING

IMPORTANT NOTE: operations involving replacement of essential components must be carried out at our workshop, especially

for instruments with flameproof certificate; this is to guarantee the user the total and correct restoration of the product original

characteristics.

MALFUNCTION PROBABLE CAUSE REMEDY

Set point shift

Permanent deformation of the sensitive element due

to fatigue or non-tolerated overages.

Variation of the elastic features of the sensitive ele-

ment due to its chemical corrosion.

O-ring wear (only MWH and MAH)

Recalibrate or replace the sensitive element.

Recalibrate or replace the sensitive element with

another made of a suitable material. If necessary

apply a fluid separator.

Replace the piston subgroup and recalibrate.

Poor repeatability

O-ring wear (only MWH and MAH)

Air bubbles or condensation (only for types with pres-

sure <1 bar).

Replace the piston subgroup and recalibrate.

Drain the process connection line and if necessary

modify it.

Slow response

Clogged or obstructed connection line.

Root valve partially closed.

Too viscous fluid.

Check and clean line.

Open valve.

Provide instrument with suitable fluid separator.

No actuation or

undue actuation

Root valve closed.

Microswitch contacts damaged.

Loosened electrical joints.

Interrupted or short-circuited electrical line.

Open the valve.

Replace the Microswitch.

Check all electrical joints.

Check the conditions of the electrical line.

Undue actuation

Accidental shocks or excessive mechanical vibra-

tions.

Modify the mounting.

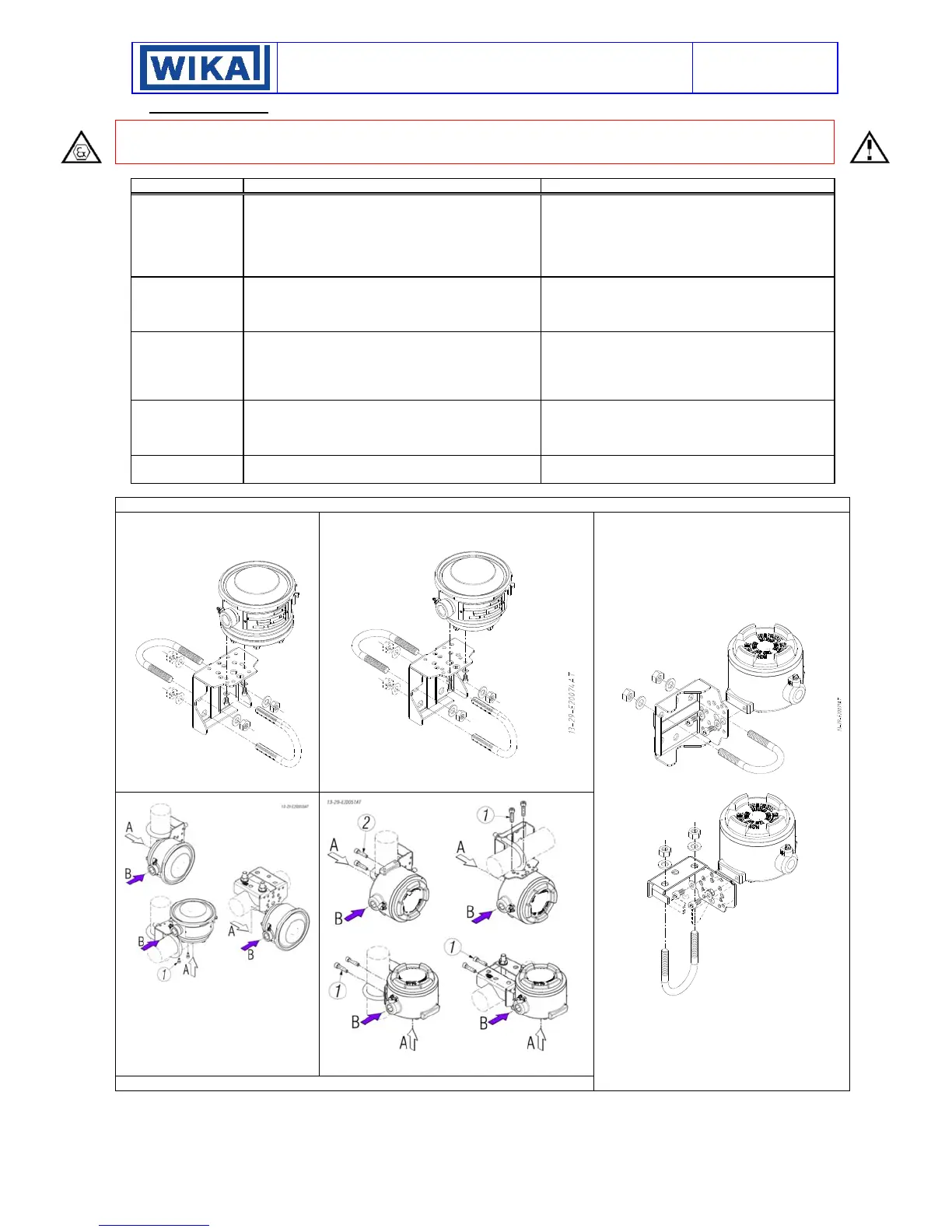

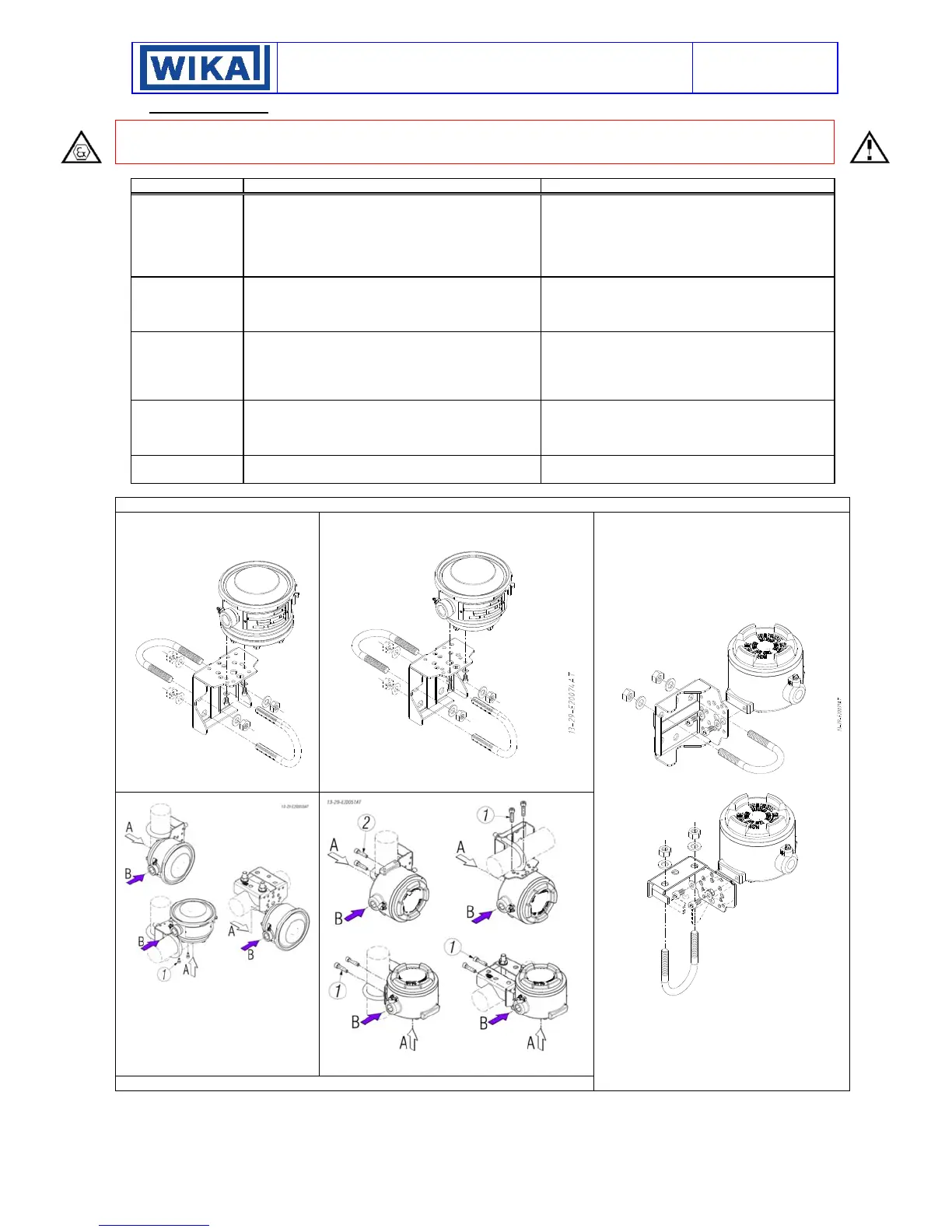

Fig. 17 – Mounting of the brackets for 2” pipe and possible position

Model MW, version MWB

Model MW (not for version MWB)

Model MA

A – Process connection B – Electrical connection

Loading...

Loading...