INSTRUCTION MANUAL

NI-221WE

Rev. 5 12/16

WIKA Alexander Wiegand SE & Co. KG

lexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

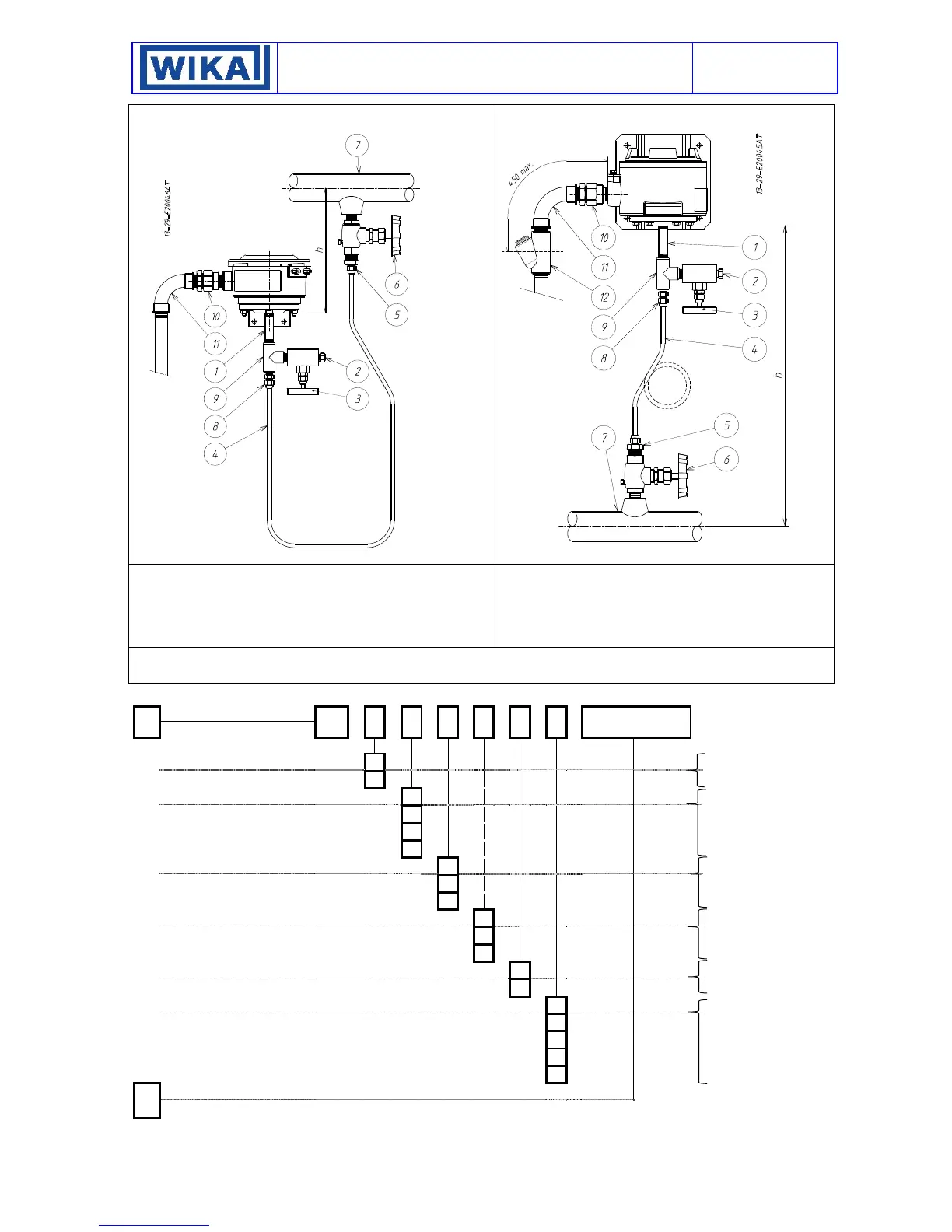

Fig. 21 - Typical installation

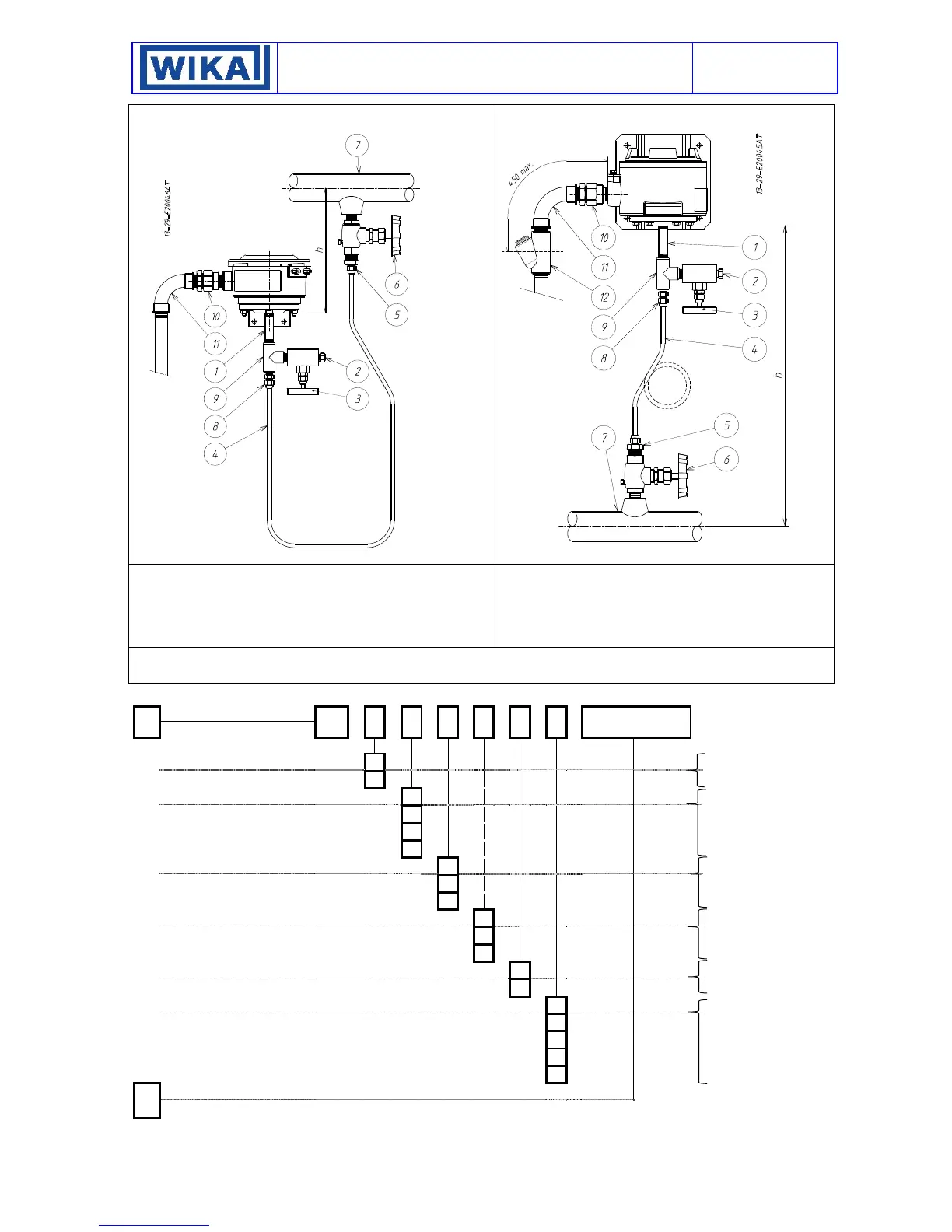

Fig. 22 - Typical installation

LEGENDA

1 - Fitting

2 - Drain plug

3 - Service valve

4 - Piping

5 - Three piece fitting

6 - Root valve with drain

7 - Process piping

8 - Three piece fitting

9 - “T” fitting

10 - Three piece fitting

11 - Curve

12 - Blocking joint

NOTE With gas or vapour process fluid, the instrument must be positioned higher than the pipe inlet (see Fig. 20). With a liquid process fluid, the

instrument can be positioned higher or lower, indifferently (see Fig. 19 e 20). In this case, during set point calibration the negative or positive head

must be taken into account (distance h in Fig.19 and 20).

Annex 1 – Model Code

1

MODEL CODE

M

For further information

see datasheet

1.1

Ignition protection mode

W

Weather proof

A

Ex d

1.2

Sensor code

B

Low pressure diaphragm

-

Medium pressure diaphragm

H

Piston

G

Piston with diaphragm

1.3

Sensor material

T

Diaphragm PTFE

X

AISI s.s. or Inconel® 718

K

Monel® 400

1.4

Process connect. material

T

PTFE

X

AISI s.s

K

Monel® 400

1.5

Electric Contacts

U

One

D

Two

1.6

Type of Electric Contact

N

Silver

S

Silver + Argon sealed

G

Gold

O

Gold + Argon sealed

R

Silver adjustable dead band

2

Options

Example: Intrinsic Safety execution

12/2018 WIKA based on 12/2016 CELLA

Loading...

Loading...