Installation

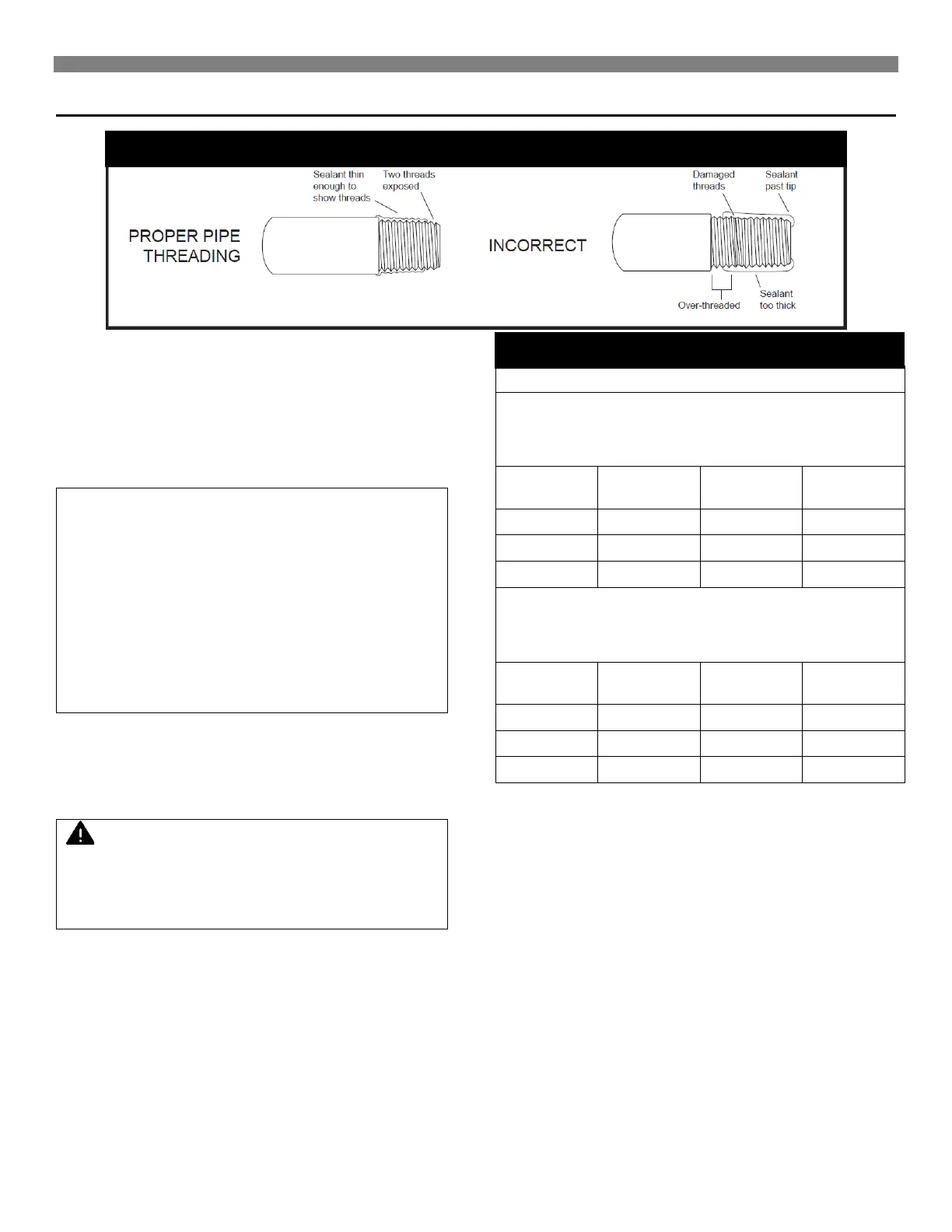

Checking the Gas Piping

Test all piping for leaks. When checking gas piping to the

furnace with gas pressure at less than 1/2 PSI, shut off manual

gas valve to the furnace. If the gas piping is to be checked with

the pressure at or above 1/2 PSI, the furnace and manual

shutoff valve must be disconnected during testing. Apply a

soap solution (or a liquid detergent) to each joint. Bubbles

forming indicate a leak. Correct even the slightest leak at once.

WARNING: Danger of property damage, bodily

injury or death. Never use a match or open flame

to test for leaks. Never exceed specified

pressures for testing. Higher pressures may

damage the gas valve and cause over firing

which may result in combustion chamber failure.

Liquefied petroleum gas (L.P.G.) is heavier than

air and it will settle in any low area, including

open depressions and it will remain there unless

area is ventilated. Never attempt start-up of the

unit before thoroughly ventilating the area and

smelling near the floor for gas odor.

Natural Gas

Pipe Capacity – Btu/hr.

(includes Fittings)

Pipe Size

L. P Gas

Pipe Capacity – Btu/hr.

(includes Fittings)

Pipe Size

When an existing category I heater is removed or replaced, the original venting system may no longer be sized to properly vent the

attached appliances.

WARNING:

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance

connected to the venting system being placed into operation

could result in carbon monoxide poisoning or death.

The following steps shall be followed for each appliance connected

to the venting system being placed into operation, while all other

appliances connected to the venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal pitch,

as required in the National Fuel Gas Code, ANSI Z223.1/NFPA

54 or the Natural Gas and Propane Installation Code, CSA

8149.1 and these instructions. Determine that there is no

blockage or restriction, leakage, corrosion and other

deficiencies which could cause an unsafe condition.

3. As far as practical, close all building doors and windows and all

doors between the space in which the appliance(s) connected

to the venting system are located and other spaces of the

building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected to the

venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they are operating at

maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so appliance is

operating continuously.

7. Test for spillage from draft hood equipped appliances at the

draft hood relief opening after 5 minutes of main burner

operation. Use the flame of a match or candle.

8. If improper venting is observed during any of the above tests,

the venting system must be corrected in accordance with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or Natural

Gas and Propane Installation Code, CSA 8149.1.

9. After it has been determined that each appliance connected to

the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace dampers

and any other gashed burning appliance to their previous

conditions of use.

Loading...

Loading...