en

28 Installation and operating instructions • Wilo-Control EC-L • Ed.04/2022-09

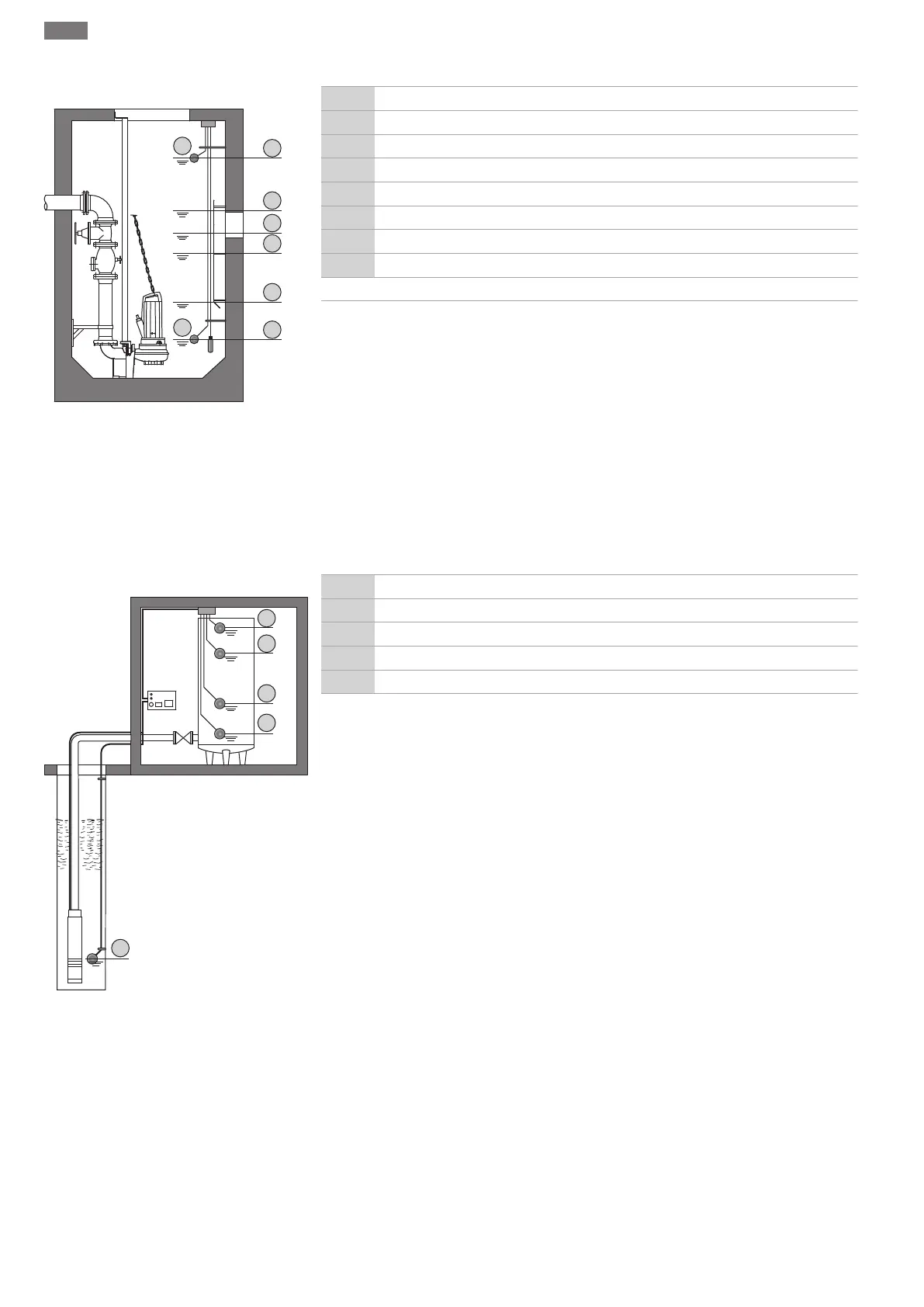

Level measurement with level sensor or dynamic pressure bell

Fig.25: Illustration of the switching points

with a level sensor in the “drain” operating

mode using the example of two pumps

1 Pump 1 On

2 Pump 1 Off

3 Pump 2 On

4 Pump 2 Off

5 Dry-running level

6 High water level

7 High water level*

8 Dry-running level*

* Also implemented via a separate float switch for increased operational reliability.

A level sensor or dynamic pressure bell can be connected. This can be used to control three

pumps:

• Pump 1 On/Off

• Pump 2 On/Off

• Pump 3 On/Off

• Dry-running level

• High water level

7.2.2 “Fill” operating mode

The reservoir is filled up, for instance, to pump water into a rainwater storage tank. The

pumps are activated when the level falls and switched off when the level rises. This control

is mainly used for water supply.

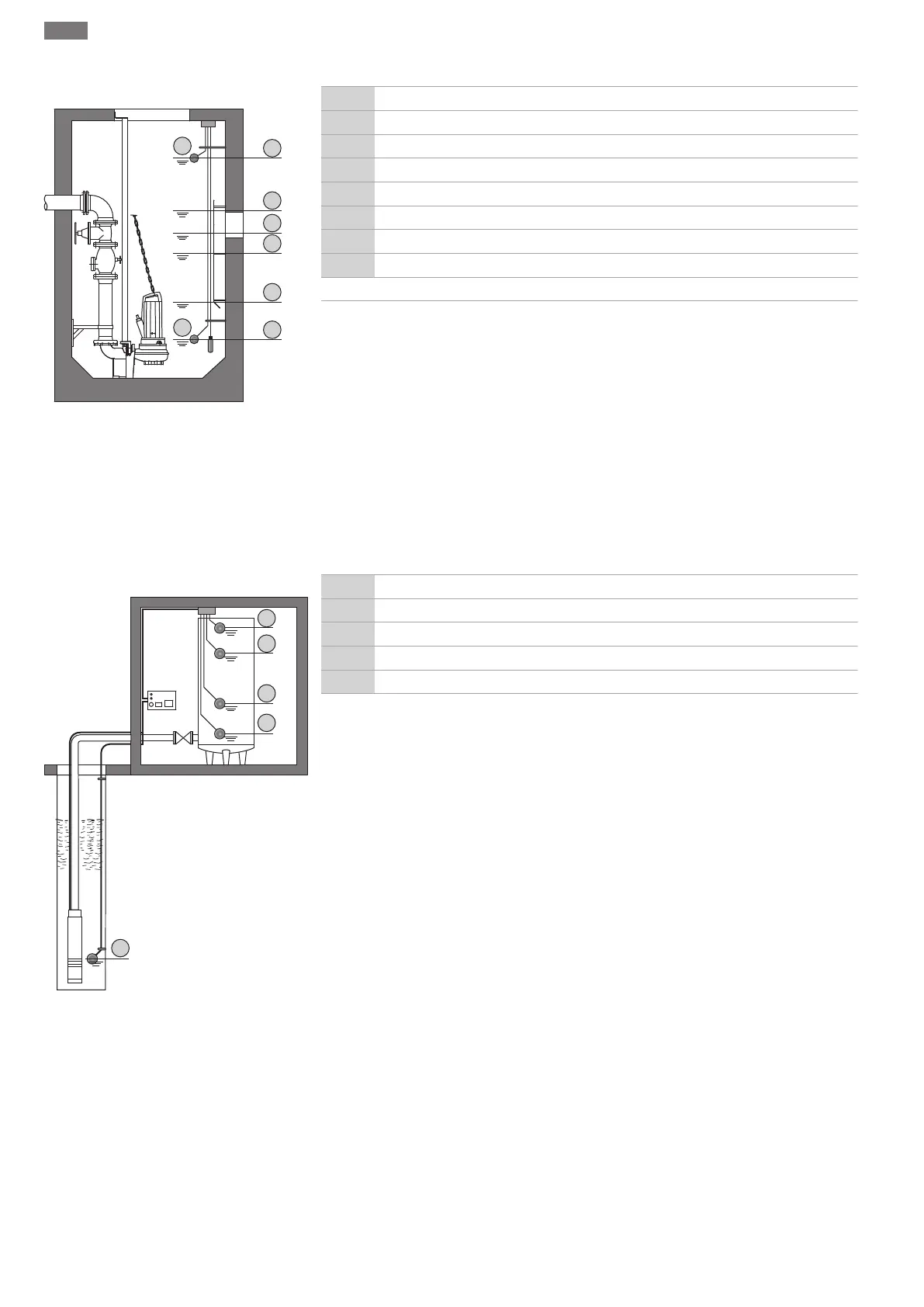

Level control for float switch or electrodes

Fig.26: Illustration of the switching points

with a float switch or electrodes in the “fill”

operating mode using the example of one

pump

1 Pump On

2 Pump OFF

3 High water level

4 Min. water level

5 Dry-running level in the well

Up to a maximum of six float switches or electrodes can be connected. This can be used to

control two pumps:

• Pump 1 On

• Pump 2 On

• Pump 1 and 2 Off

• Min. water level in the tank to be filled

• High water level

• Dry-running level in the well (separate float switch at the “Extern OFF” input)

The float switch should be equipped with a NO contact: Once the switching point has been

reached, the contact is closed.

Loading...

Loading...