4 50-18-002-0817

8 Problems, Causes and Solutions

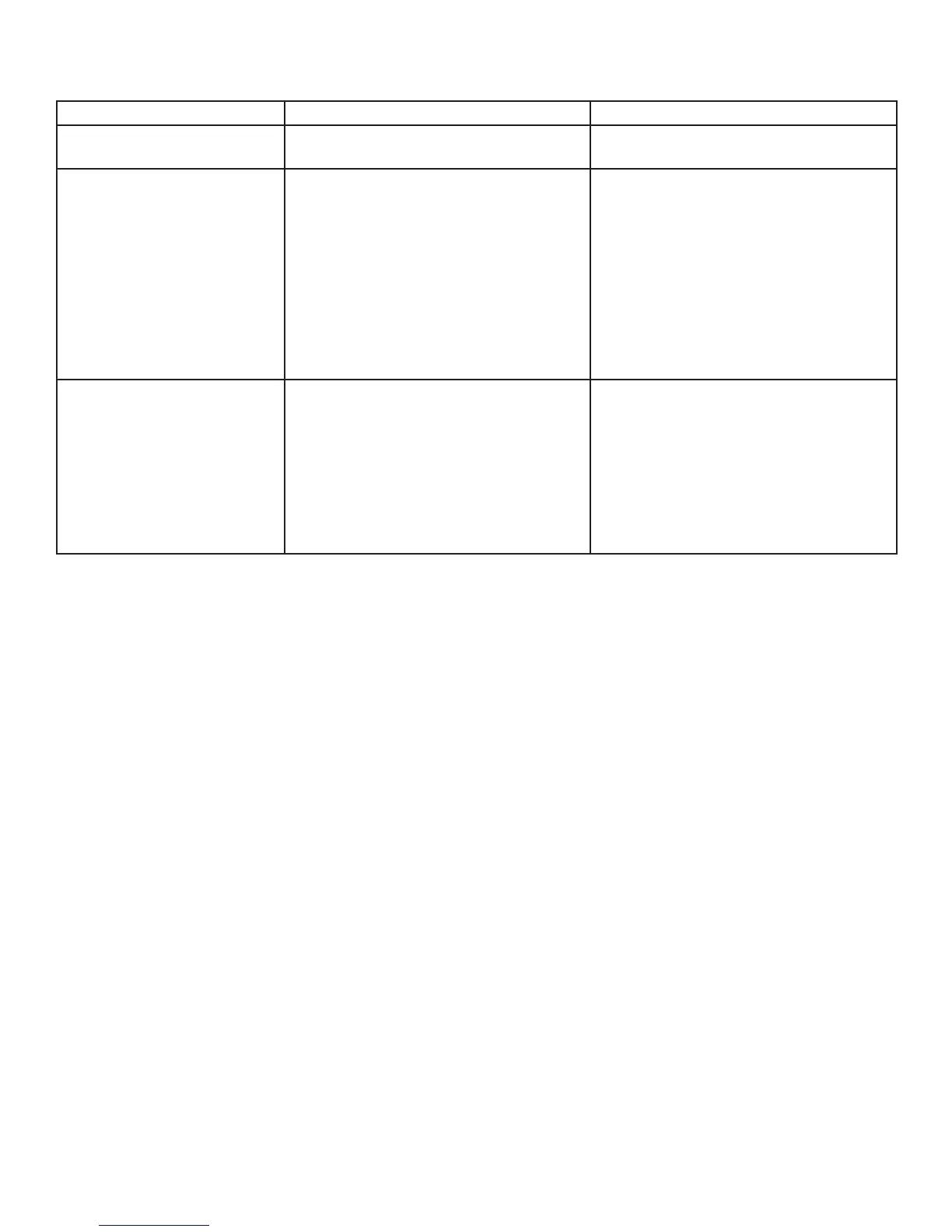

Problems Causes Solutions

The motor does not run Consult motor manufacturer’s

documentation for trouble shooting tips.

No or insufcient capacity a. Voltage too low

b. Suction lter blocked

c. Incorrect motor direction of rotation

d. Low-water protection or water level in well

too low

a. Check electrical power supply at

switchgear.

b. Lift pump out of bore-hole, clean suction.

c. Swap any two phases in the switchgear.

d. Check water level in bore-hole/well; it

must be at least 8” (20” if 8’’ motor) above

the pump pressure pipe connection (during

operation).

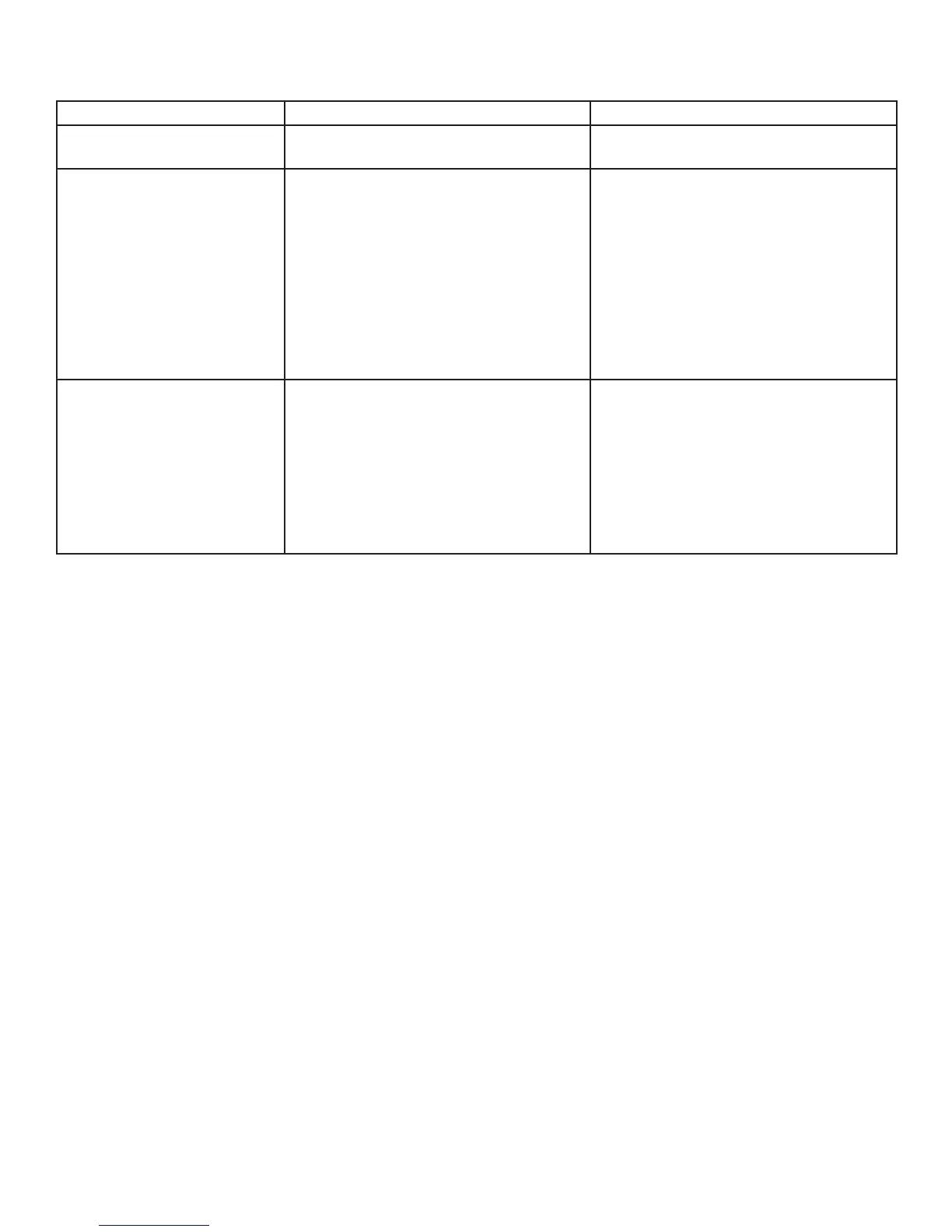

Pump switches on too frequently a. Insufcient switching difference between

on/off pressure in pressure switch/gauge

b. Storage volume of diaphragm pressure

vessel too small or pre-pressure setting too

low

a. Increase difference between on and off

points

b.

• Check switching pressure settings and reset

• Check vessel pre-pressure (no water in

vessel)

• Provide additional pressure vessel or install

tank with greater nominal volume.

If the fault cannot be remedied, please contact a Wilo authorized pump installer.

Subject to technical alterations!

Loading...

Loading...