English

39WILO SE 09/2013

7.2 Description (Fig. 1, 2, 5, 6, 7, 8)

1 - Strainer-foot valve

2 - Pump suction valve

3 - Pump discharge valve

4 - Non-return valve

5 - Venting and filling plug

6 - Drain-priming plug

7 - Pipe supports or brackets

8 - Strainer

9 - Storage tank

10 - Town water supply

11 - Disconnecting switch with fuses

12 - Lifting hook

13 - Foundation block

14 - Cock

15 - Pressure sensor

16 - Tank

17 - Insulation valve of the tank

18 - Switch block

19 - Pump identification sticker

BP - By-pass

HA - Maximum suction head

HC - Minimum inlet pressure

7.3 Installation

Two standard types.

Fig. 1: pump in suction

Fig. 2: pump in load on storage tank (item 9) or

town water supply (item 10).

- Install the pump in a place easy to reach, pro-

tected against frost and as close as possible from

the drawing point.

- For heavy pumps provide a point of attachment

(lifting hook) in the pump axis (item 12) to facili-

tate removal.

- Install the pump on a concrete block (at least 10

cm high) (item 13) and fix with anchor bolts

(installation plan see Fig. 3).

- Foresee an insulating material under the concrete

block (cork or reinforced rubber) to avoid any

noise and vibration transmission into the installa-

tion.

- Before final tightening of anchor bolts, ensure that

the pump axis is vertical: use shims if necessary.

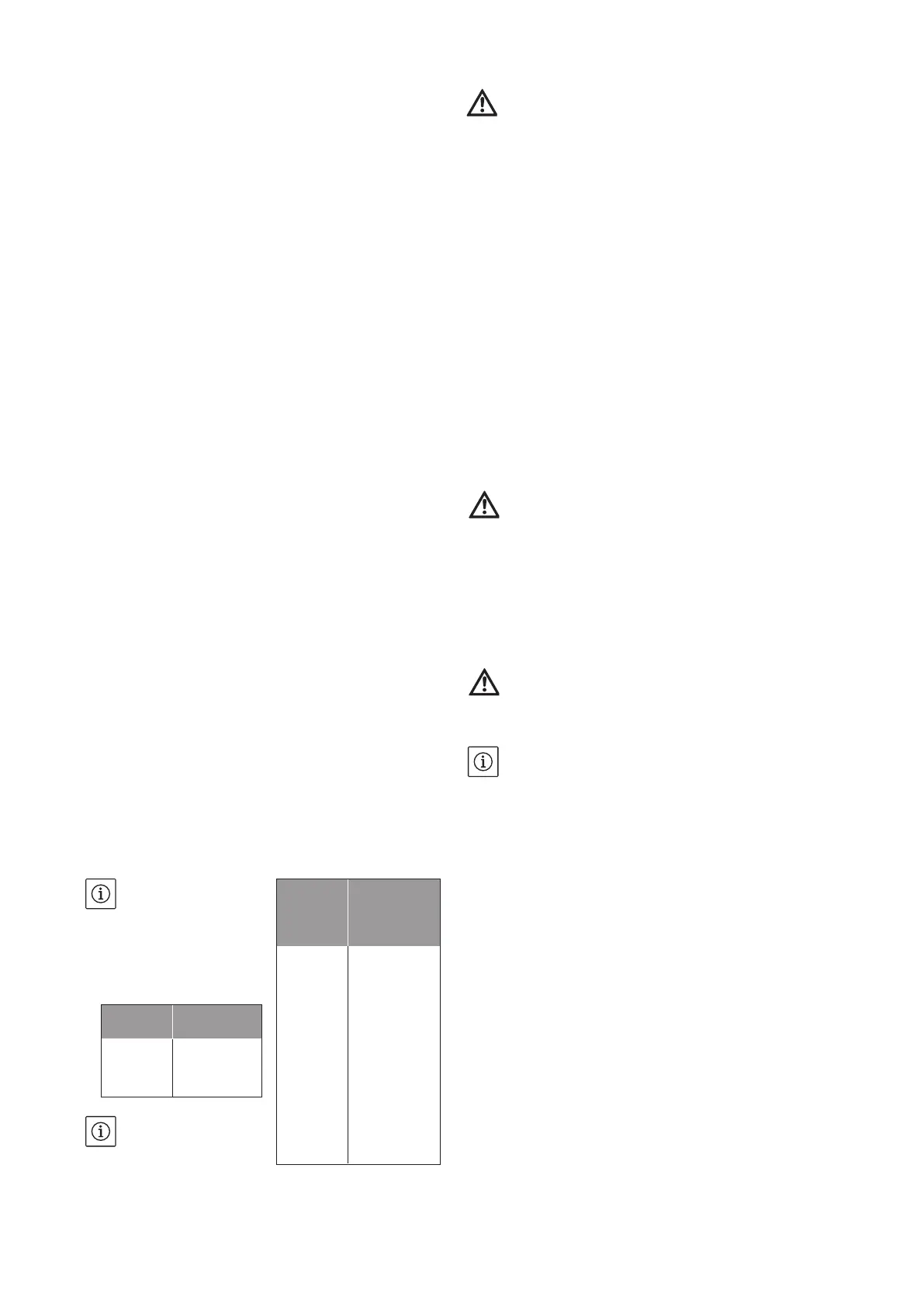

NOTE: Keep in mind

that the altitude of the

installation place and

the water temperature

may reduce the suction

possibilities of the

pump.

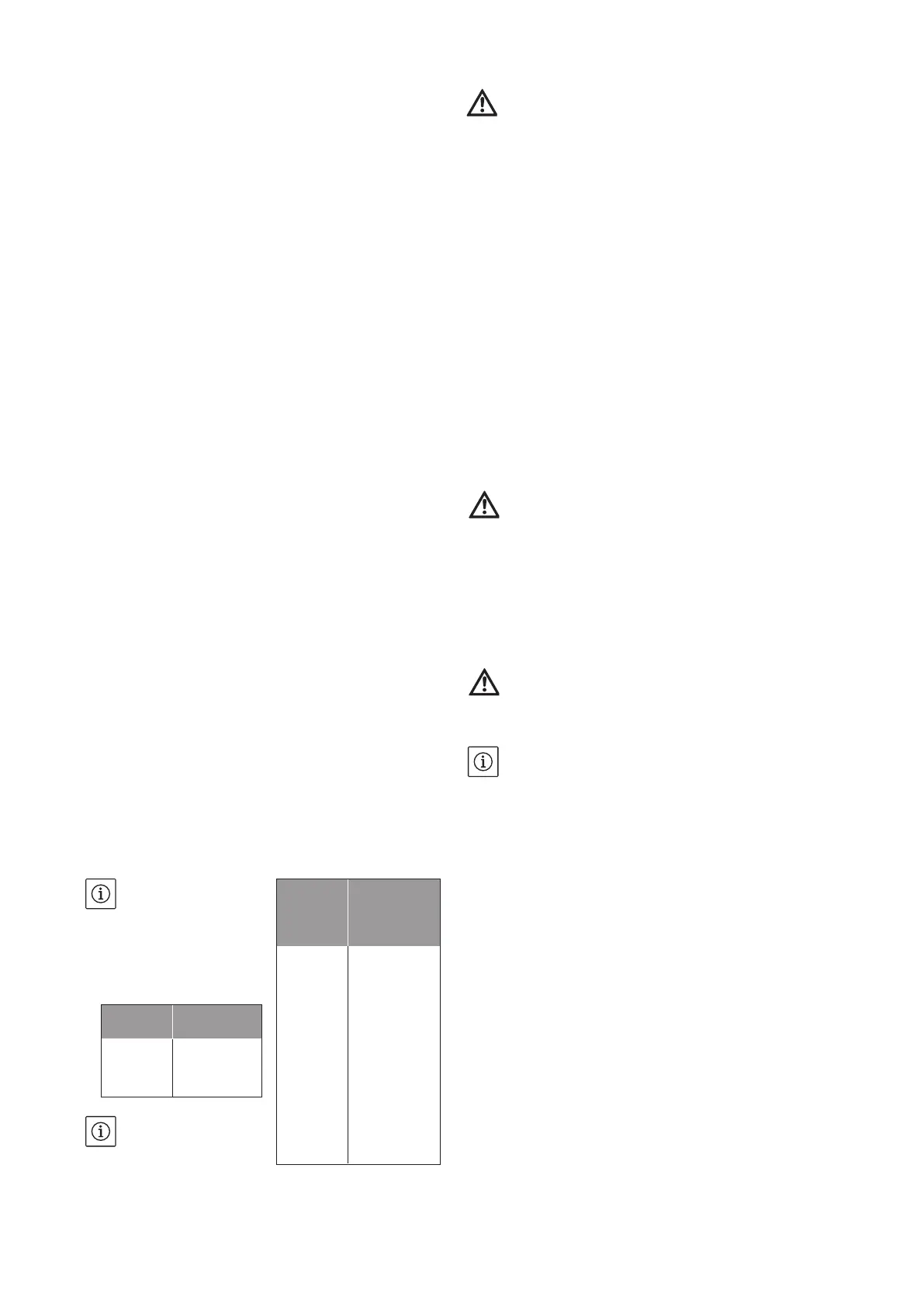

NOTE: Beyond 80° C,

plan to install the pump

in load.

CAUTION! Danger of material damage!

The installation has to bear the pressure reached

when the pump runs at maximum frequency and

zero flow rate.

- Pump with oval flange pump casing : with

threaded screw-on tubes directly on the tapped

oval counterflanges delivered with the pump.

- Pump with round flange pump casing: with

weld-on or screw-on tube in the counterflanges

(counterflanges available as accessories).

- Pump casing with rapid hose coupling : with a

bracket, to be installed with an end to be fixed

on the pipe (bracket and threaded end available

as accessories).

- The diameter of the pipe must never be smaller

than the one of the counterflange.

- Pumps series 400, 800, 1600/6: the direction of

the fluid flow is indicated on the pump identifi-

cation sticker.

- Pumps series 2200, 7000, 9500: an arrow on the

pump casing shows the direction of the fluid

flow.

CAUTION! Danger of material damage!

Connections have to be correctly sealed, no air

entrance is allowed on the suction pipe which

shows a minimum mounting declivity of 2% (Fig.

1).

- Limit the length of the suction pipe and avoid all

features that cause losses of head (bends, valves,

tapers).

- Use supports or collars (Fig. 1, 2, item 7) so that

the pump does not bear the weight of the pipes.

CAUTION! Danger of material damage!

When the pump is in load, it is recommended to

connect the non-return valve to the pump dis-

charge to protect it against hammer blow effects.

NOTE: To pump water with a large content of air

or hot water, we recommend to install the

bypass kit (Fig. 1, item BP). Mount the pressure

sensor on the discharge pipe (Fig. 7).

Altitude Loss of head

0 m 0 mCL

500 m 0,60 mCL

1000 m 1,15 mCL

Tempe-

rature

Loss of head

20°C 0,20 mCL

30°C 0,40 mCL

40°C 0,70 mCL

(50°C) 1,20 mCL

(60°C) 1,90 mCL

(70°C) 3,10 mCL

(80°C) 4,70 mCL

(90°C) 7,10 mCL

(100°C) 10,30 mCL

(110°C) 14,70 mCL

(120°C) 20,50 mCL

Loading...

Loading...