29

3062049_201610

KG TopMaintenance

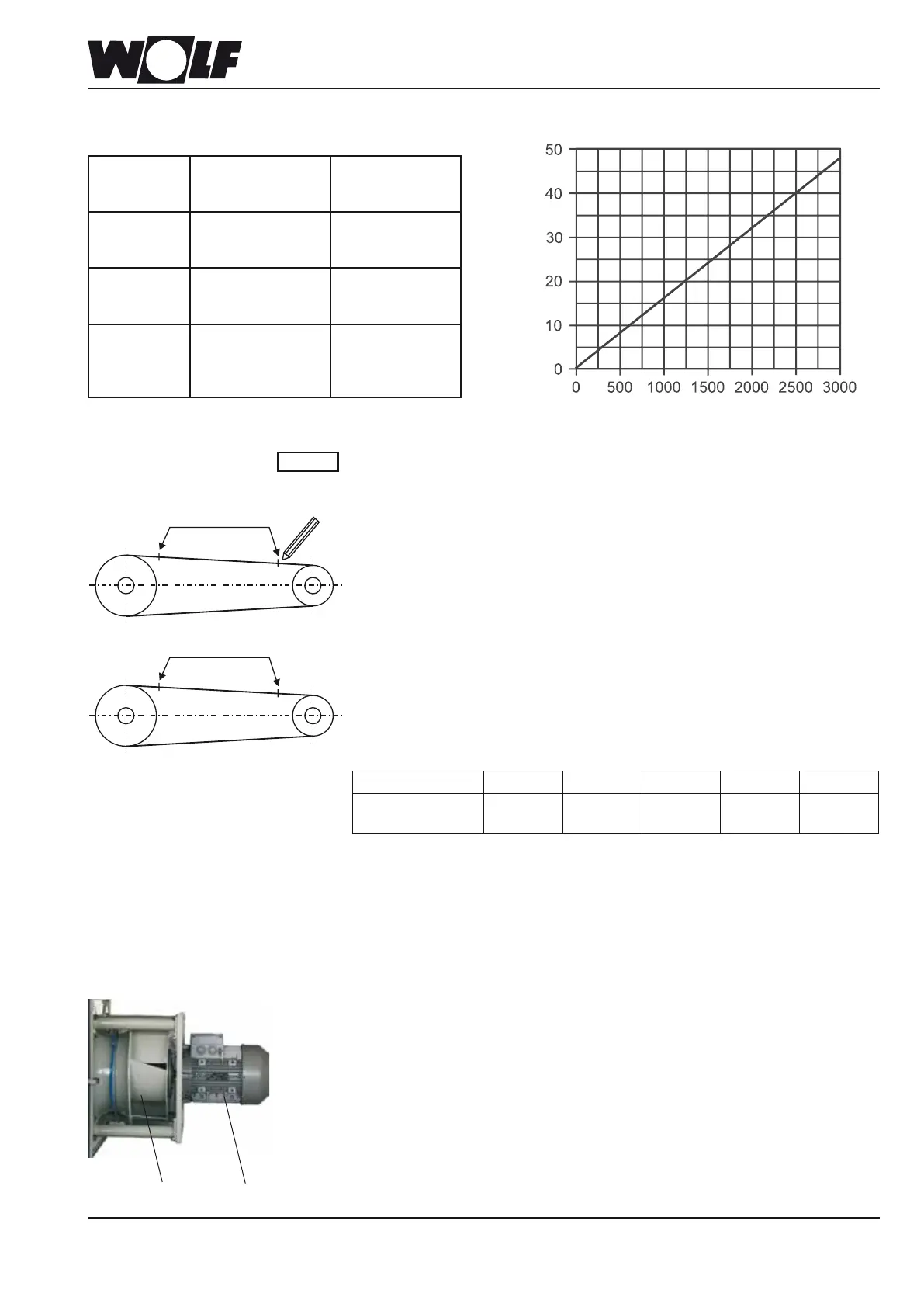

Free running fan impeller

Observesafetyandemploymentregulations(BSEN50110,IEC364)whencarrying

out repair and maintenance work!

Motor and bearing are maintenance free.

Check the fan for mechanical vibrations in accordance with BS ISO 14694 every 12 months.

The max. permissible vibration severity is 2.8 mm/s (measured on the bearing plate of

the bearing at the impeller end of the motor).

Deposits on the impeller can lead to imbalance and thus to damage (danger of a fatigue

fracture – impeller can break up – danger to life).

Clean the impeller with soapy solution if required.

Fan impeller Motor

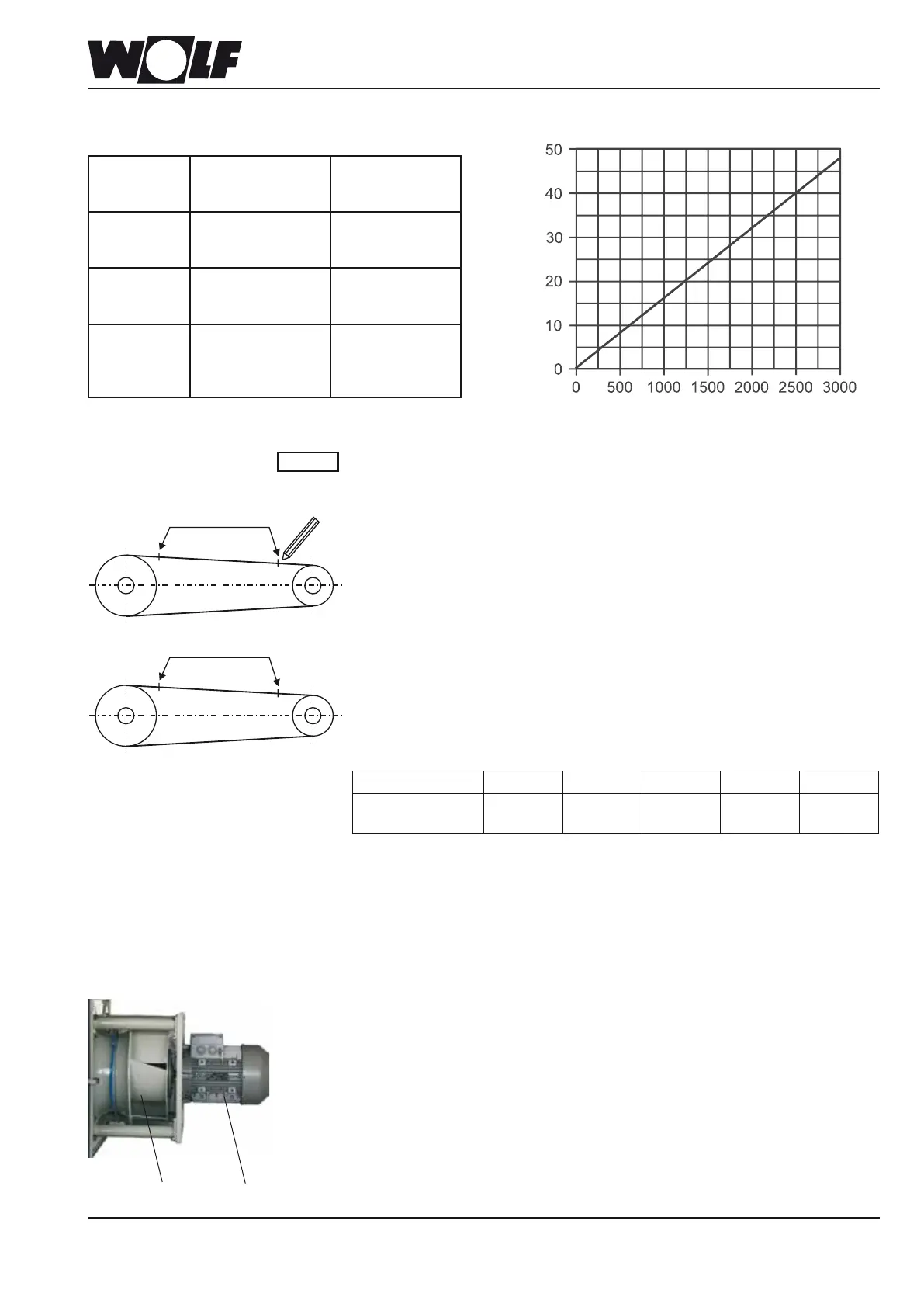

Testforces(F)anddeectionvalue(x)fornarrowhighperformancevee-beltsDIN7753

Beltprole Effective diameter

of the small pulley

(mm)

Force F

(N / belt)

SPZ 67 - 95

100 - 140

150 - 200

10 - 19

15 - 20

19 - 27

SPA 100 - 132

140 - 200

224 - 315

20 - 27

28 - 35

35 - 50

SPB 180 - 224

236 - 315

315 - 400

400 - 500

40 - 52

46 - 60

55 - 76

67 - 90

Deectionx(mm)

Axis clearance A (mm)

Flat belt drive

Check the precise parallelism of the fan drive shaft to the motor drive shaft.

Check the precise alignment of the pulleys.

Clean the pulley belt faces thoroughly to remove dirt, oil and grease.

Using a pencil, apply measuring marks to the belt at distances of, for example, 250 mm,

350 mm, 500 mm, 750 mm and 1000 mm.

Prior to the test run, turn the pulleys manually to check the belts run correctly.

Check the belts after a test run lasting 30 to 60 minutes and increase the pretension

(max. 2%) if required.

When using collared/weald pulleys ensure that the belt has no permanent contact with

the collar or weald during operation. This would lead to the destruction of the belt.

Note

Test marks

Test marks

max. +2%

250/350/500

Examples - test mark clearances:

Unstretched 250 mm 350 mm 500 mm 750 mm 1000 mm

Stretched

+ max. 2%

max.

255 mm

max.

357 mm

max.

510 mm

max.

765 mm

max.

1020 mm

Loading...

Loading...