Operation 15

MAN0988 (11/5/2012)

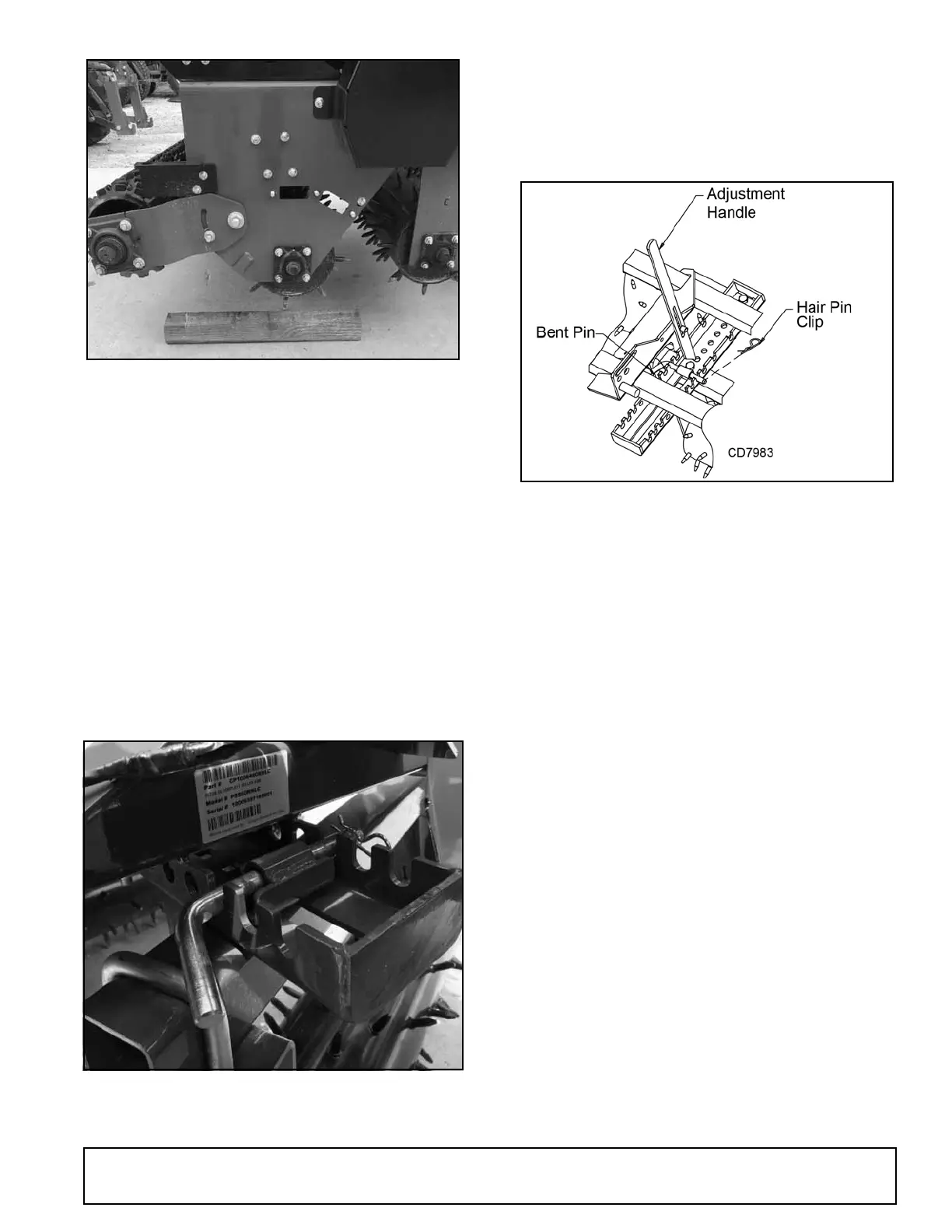

Figure 13. Precision Super Seeder above Wooden

Blocks

6. Lower seeder to resting position on wooden blocks

for support during front roller adjustment. (Follow

tractor safe parking procedure in tractor operator’s

manual).

7. Raise the adjustment handle and pivot it to the next

adjustment hole (see Figure 15). Move handle

rearward; front rollers will start to angle forward.

Continue this process until front rollers have the

desired angle and holes align between frame rail

and roller side weldment.

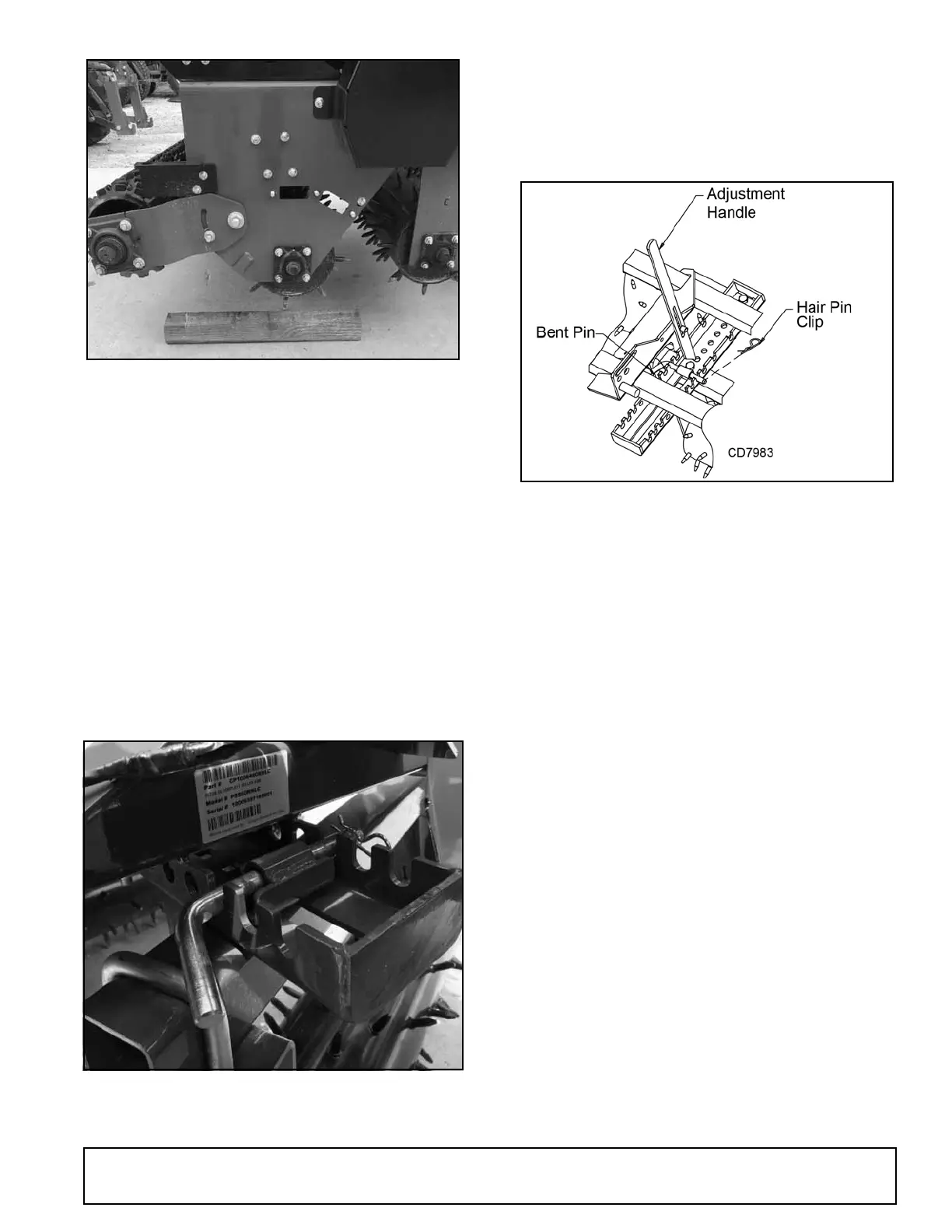

8. Partially engage bent pin to hold adjusted position.

9. Lift seeder and pull forward to clear wooden

blocks. Lower seeder to rest position on the

ground/level surface, and fully install bent pin and

hair pin clip (see Figure 14).

Figure 14. Bent Pin Installation

10. Reverse this procedure to move front roller back

into straight position.

NOTICE: The 72" and 84" seeders use the front

notch of the frame rail for the maximum roller angle

(19° and 17° respectively). The 60" seeder uses

the 2nd notch from the front for the maximum roller

angle (20°). The 48" seeder uses the 3rd notch

from the front for the maximum roller angle (20°).

Figure 15. Spike Roller Handle Adjustment (mast

plate hidden for picture clarity)

Adjust Front Disc Angle

1. Position tractor and Precision Super Seeder on a

level surface.

2. Set seeder on the ground and set parking brake.

3. Remove bent pin and hair pin clip from front of

seeder (see Figure 12).

4. Place wooden blocks (minimum 4" thickness) on

ground to align with each end of the Precision

Super Seeder.

5. Raise seeder slightly off the ground and position

seeder over wooden blocks by moving tractor. Do

not allow wooden block to contact the front disc

gang (see Figure 13.)

6. Lower seeder to resting position on wooden blocks

for support during front disc adjustment. (Follow

tractor safe parking procedure in tractor operator’s

manual.)

7. Raise the adjustment handle and pivot it to the next

adjustment role (see Figure 15). Move handle

forward; front discs will start to angle rearward.

Continue this process until front discs have the

desired angle and holes align between from rail

and disc slide weldment.

8. Partially engage bent pin to hold adjusted position.

9. Lift seeder and pull forward to clear wooden

blocks. Lower seeder to rest position on the

ground/level surface, and fully install bent pin and

hair pin clip (see Figure 14).

(Rev. 7/12/2019)

Loading...

Loading...