Assembly 43

MAN0943 (11/1/2013)

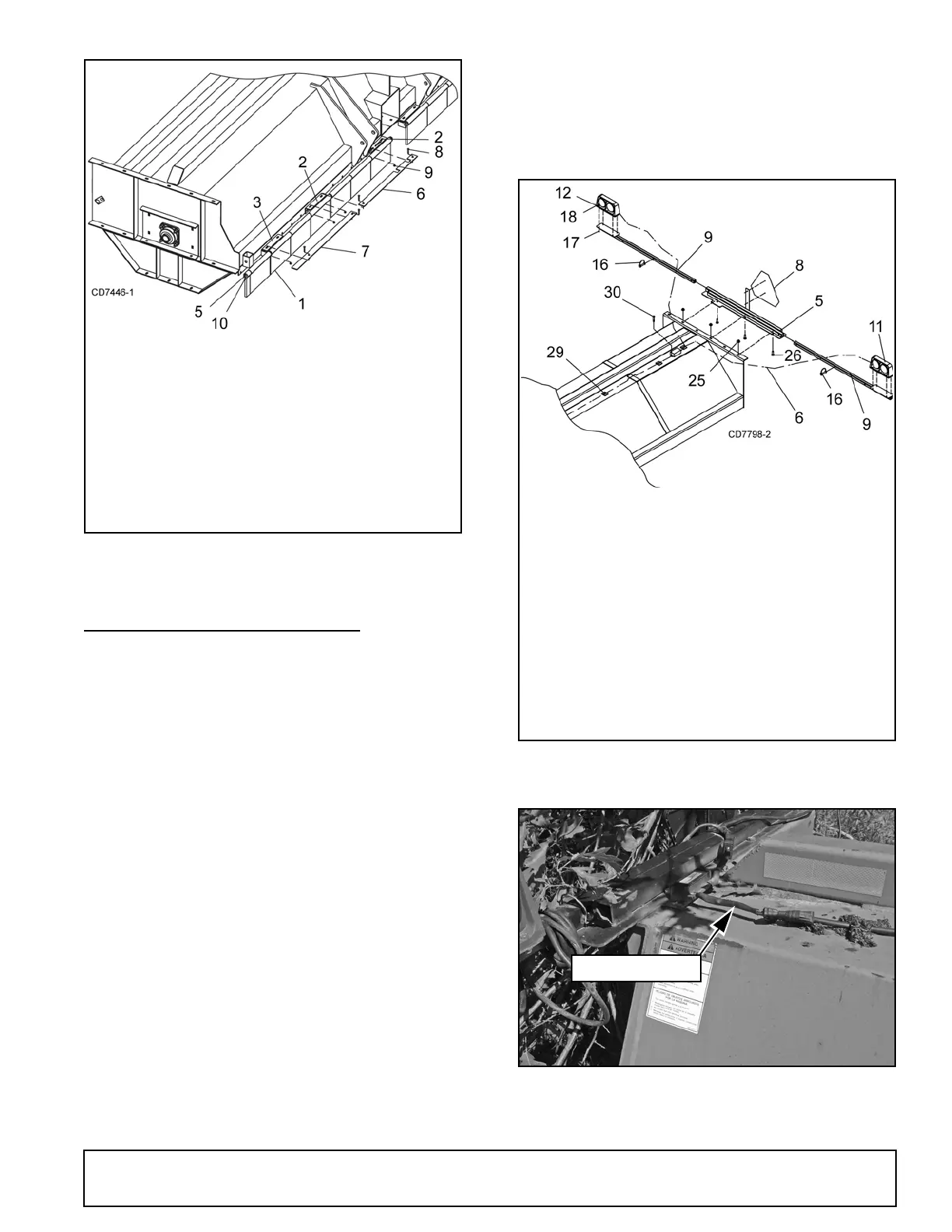

Figure 54. Rubber Flap Installation (15’ Shown)

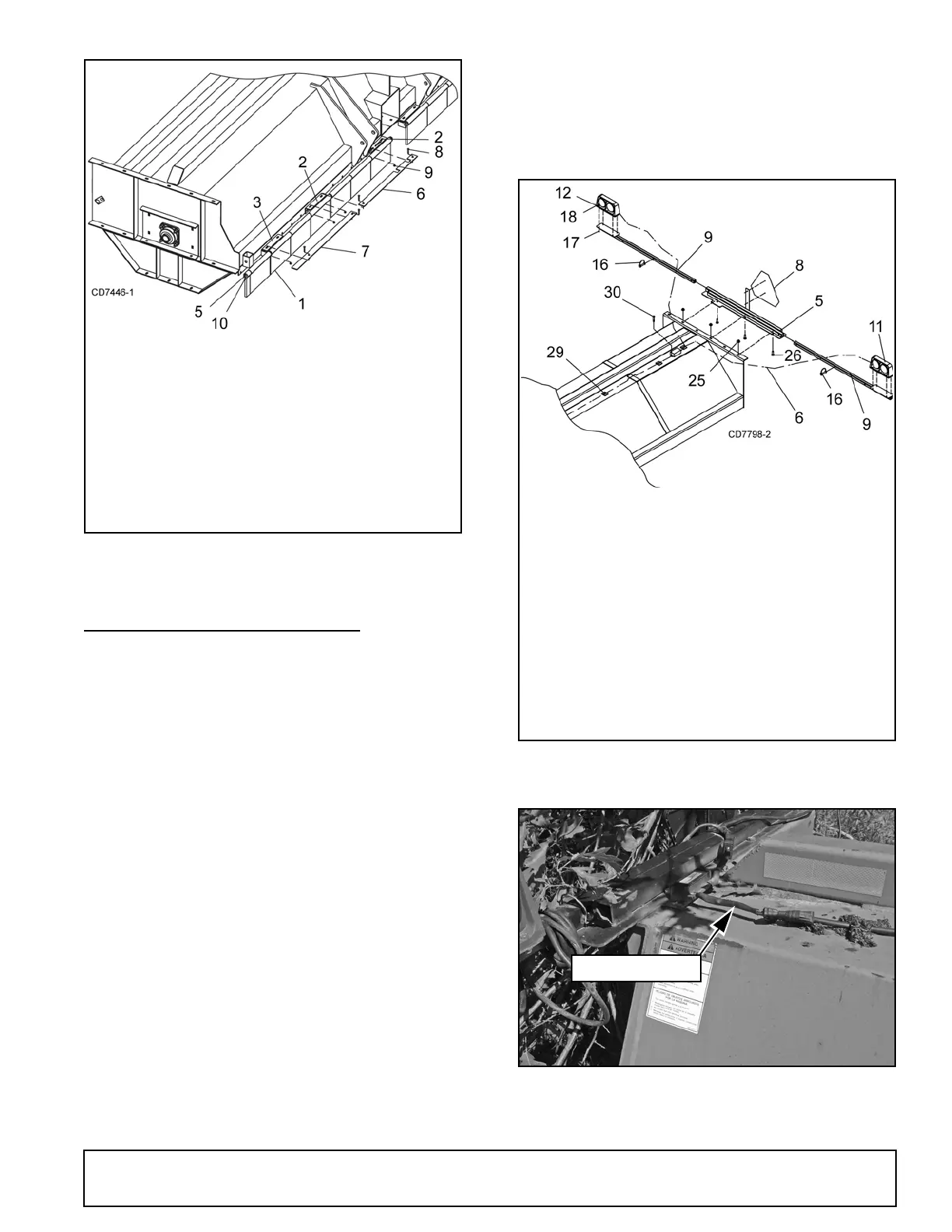

SAFETY LIGHT INSTALLATION

1. Remove all components from shipping carton.

Make sure that all required hardware is included.

2. Attach dual safety lights (Figure 48) to safety light

mounting brackets (9) using cap screws (17) and

lock nuts (18).

NOTE: Make sure that light lenses are in the cor-

rect position in relation to direction of equipment

travel: amber lenses on the outside, red lenses on

the inside facing rear of shredder.

3. Install light bracket (5) on end of shredder using

cap screws (26) and lock nuts (25) on top of end

sheet.

4. Attach light mounting brackets (9) to light bracket

(5) using pins (16).

5. Secure SMV sign (8) to light bracket (5).

6. Plug ends of wiring harness into corresponding

plugs of the light units

NOTE: Left side of wishbone harness is labeled

“Left”.

7. Run wiring harness along top of shredder and

secure with enclosed adhesive-backed clamps

(29) approximately every two feet.

8. Secure wiring harness module to top of shredder

using self tapping screw (30).

9. Connect 7-pin connector of wiring harness to

tractor and test all light functions before actual use.

Figure 55. Safety Light Installed

Figure 56. Safety Light Wiring

1. Rubber flap

2. Flap bracket, right

3. Flap bracket, left

5. flap rod

6. Swing flap bar, mast plate

7. Swing flap bar

8. 3/8 NC x 1 Carriage bolt

9. 3/8 NC Flange lock nut

10.3/16 x 1-1/2 Cotter pin

5. Light Assembly Mounting Bracket

8. SMV Sign

9. Safety Light Mounting Bracket

11. Dual Lamp - Left Hand

12. Dual Lamp - Right Hand

16.Pin

17. 1/4 Flange Lock Nut

18. 1/4 NC x 1 HHCS

26. 1/2 NC x 1-1/2 Carriage Bolt

29. Adhesive backed clamps

30.5/16 NC x 3/4 Self Tap Screw

Loading...

Loading...