1

0.5.

FINAL

INSTALLATION

Remove

the automatic

air

vent cap.

See

Fig.

1

9.

Replace

the inner

casing

coVEr.

See

Fig.

22.

Check

that

all

the gas and water connections

on

the

manifold

have

been

ti

ghtened.

Remove

the

fa

cia

panel as described

in

Section

14.2

(a).

Facia Mounted Programmer

Unplug the Operating Switch connection at the control board.

Unscrew

and retain the

four

nuts and washers securing the switch

mounting plate to the

facia

.

See

Fig.

40

.

Remove

the plate.

Fit

the

programmer to the

facia

and

fix

using the

four

nuts and washers.

Plug

the lead into the connection

X14

on

the main driver board.

See

Fig.

9b

.

The

programmer can be set when the electricity sup·

ply has been turned on at the commissioning stage.

Connect

the mains electricity supply to the appliance and connect

any room and/ or

frost

thermostats.

Refer

to

Section

9,

Figs.

7 and

8.

The

leads

from

the thermostats must pass through the holes

provided

in

the control box at the right hand side and be clamped

using the strain

relief

bushes provided

in

the pack.

Check

that the

control box can be withdrawn and

lowered

before

fixing

any

leads

outs

ide

the appliance.

To

remove

t

he

control box

refer

to

Section

14.2

(b).

Refit

the control

box

and

facia.

Test

the gas supply

for

soundness as indicated

in

BS

6891

.

If the appliance

is

not to be commissioned immediately, replace

the inner cover panel and the cabinet front pan

el.

See

Fig

.

22

.

Check

that the gas supply, the

electrical

supply and the water

con

-

nections are a

ll

turned

off

.

11

. Commissioning

11

. 1

The

appliance

is

despatched

with

the controls set to

provide

a maximum output

for

domestic hot water

of

35.

2kW

(120,000

Btu

/

h)

and satisfy a central heating load up to 15kW

(51

,200

Btu

/

h)

.

The

controls can be reset to increase the central heating

load capability up

to

25kW

(85

,300

Btu

/

h)

.

It

is

no

t necessary to

set an output betw

ee

n these

figures.

Domestic Hot Water System

Confirm

that the mains water supply has been

fully

flushed

out at

installation.

If

not,

it

will

be necessary

to

disconnect the

cold

water

inlet

pipe

from

the appliance and thoroughly

flush

.

Central Heating System

Confirm

that t

he

central

he

ating system has been

fully

flushed

out

at

in

stallation

usin

g a flushing agent.

If

not, after the addition

of

a

su

it

able

flushing

agent, drain whilst hot and immediately

refill

and

re-pressurise. A suitable proprietary inhibitor should be added

when

refilling.

Further

information

can be obtained

from

Worcester

Heat

Systems.

11.2

APPLIANCE AND SYSTEM PREPARATION.

Check

that the gas service and the electrical supply to the appli-

ance are o

ff

.

Check

that the

Operating

Sw

itch

(or

progr

ammer)

is

set

to

OFF

.

Se

e

Fig

.

20.

Check

that

all

the water connections throughout the system are

tight.

Remove

the cabinet

fr

ont panel

by

pu;lling forward at the

bottom and

lifting

it

off

the top supports.

Remove

the inner

cover

panel

by

uns

crewin

g the

four

screws.

See

Fig.

22.

Unscrew

the two screws at each

en

d

of

the control box.

Pu

ll

for

-

ward and

low

er the control box assemb

ly

. S

ee

Fig.

22.

Open

the central heating system

valves

on the

manifold.

See

Fig

.

21.

Open

all

the radiator valves and

fill

the system.

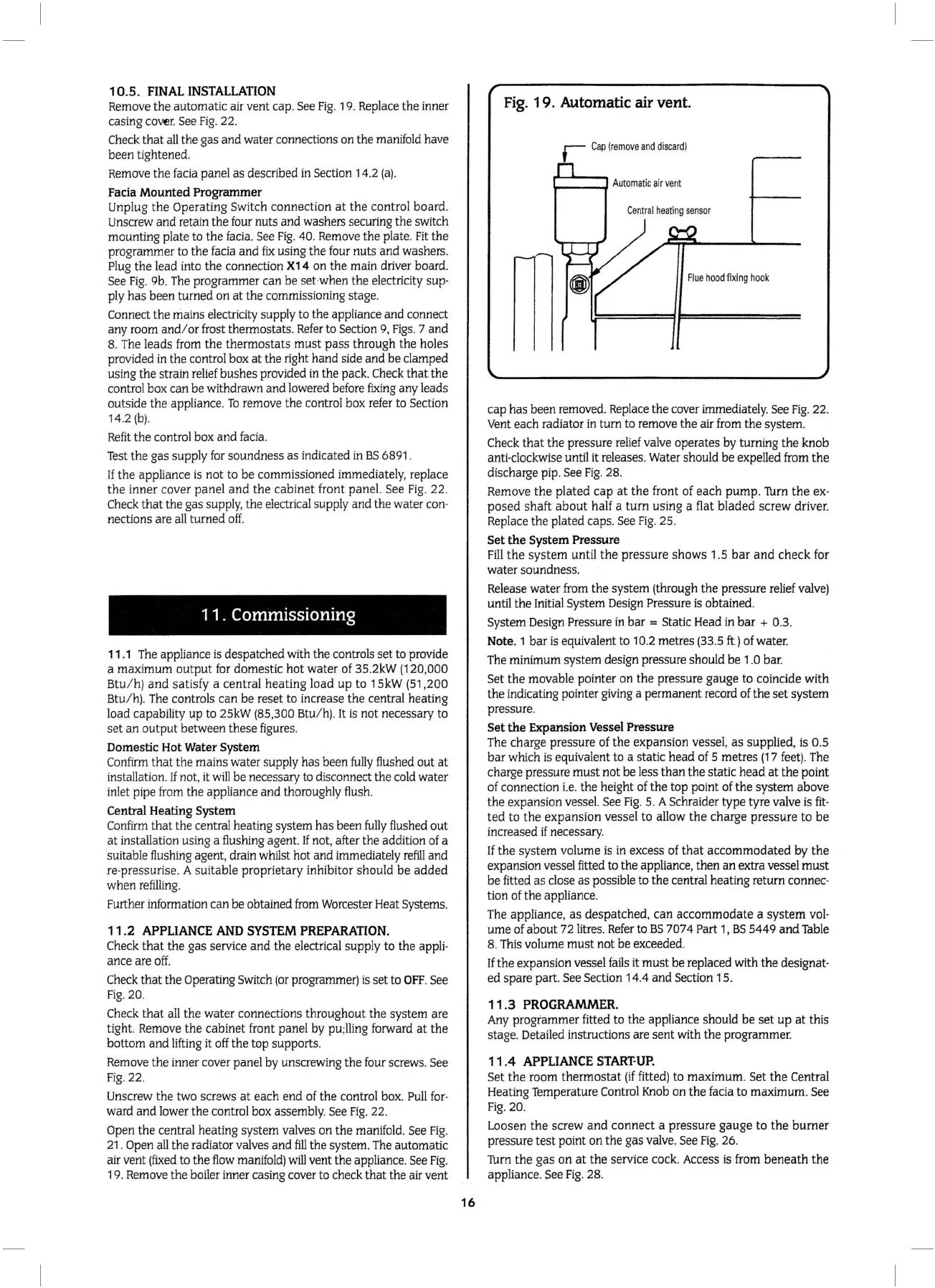

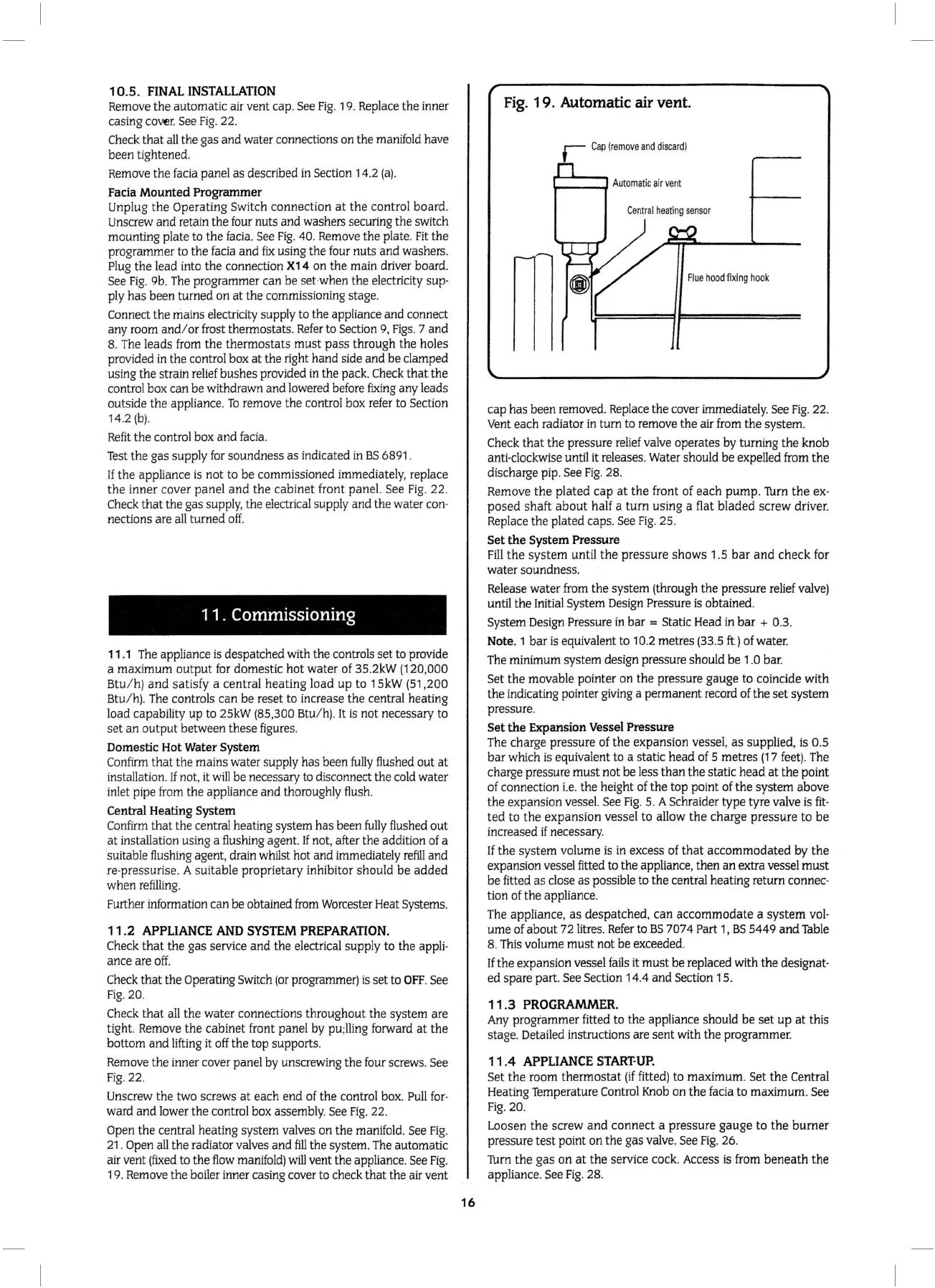

The

automatic

air vent

(fixed

to the

flow

manifold)

will

vent the appliance.

See

Fig.

1

9.

Remove

the

boiler

inner casing

co

ve

r

to

check that the

air

vent

16

Fig. 1

9.

Automatic air vent.

Flue

hood

fixing

hook

cap has been

removed.

Replace

the

cover

immediately.

See

Fig

.

22

.

Vent

each radiator

in

tum to remove the air

from

the system.

Check

that the pressure

relie

f

valve

operates

by

turning the knob

anti

-clockwise

until

it

releases.

Water

should be expelled

from

the

discharge

pip.

See

Fig.

28.

Remove

the plated cap at the front of each pump.

1\Jrn

the

ex-

posed shaft about half a

tum

using a flat bladed screw driver.

Replace

the plated caps.

See

Fig.

25.

Set the System Pressure

Fill

the system until the pressure shows 1 .5 bar and check

for

water soundness.

Release

water

from

the system (through the pressure

relief

valve

)

until the

Initial

System

Design

Pressure

is

obtained.

Syst

em

Design

Pressure

in

bar = Static

Head

in

bar + 0.3.

Note. 1 bar

is

equivalent

to

10.2

metres

(33

.5

ft

.)

of

water.

The

minimum system design pressure should be 1

.0

bar.

Set

the movable pointer

on

the pressure gauge to coincide with

the indicating pointer

giving

a permanent

record

of the set system

pressure.

Set the Expansion Vessel Pressure

The

charge pressure

of

the expansion vesse

l,

as supplied,

is

0.5

bar

wh

ich

is

equivalent

to

a static head

of

5 metres (17

feet)

.

The

charge pressure must not be less than the static head at the point

of connection

i.e.

the height

of

the top point of the system above

the expansion vessel.

See

Fig

. 5. A Schraider type tyre

valve

is

fit-

ted

to

the expansion vessel to allow the charge pressure to

be

increased

if

necessary.

If

the system volume

is

in

excess

of

that accommodated by the

expansion vessel fitted to the appliance, then

an

ex

tra vessel must

be fitted as close as possible

to

the central heating return connec-

tion of the appliance.

The

appliance, as despatched, can accommodate a system val·

ume of about

72

litres.

Refer

to

BS

707 4 Part

1,

BS

5449 and

Table

8.

This

volume must not

be

exceeded.

If

the expansion vessel

fails

it

must be replaced with the designa

t-

ed spare part.

See

Section

14.4 and Section

15.

11.3

PROGRAMMER.

Any

programmer fitted

to

the appliance should be set up at this

stage.

Detailed

instructions are sent with the programmer.

11

.4

APPLIANCE

START·UP.

Set the room thermostat

(if

fitted) to maximum. Set the Central

Heating

Temp

erature

Control

Knob

on

the

facia

to maximum.

See

Fig

. 20.

Loosen the screw and connect a pressure gauge to the burner

pressure test point on the gas

valve

.

See

Fig

.

26

.

1\Jm

the gas on at the service cock.

Access

is

from

beneath the

appliance.

See

Fig.

28.

Loading...

Loading...