VESDA by Xtralis

VESDA VFT Product Guide

www.xtralis.com 13

Detector Access

To gain access to the interior of the detector, first disconnect the power supply then remove the front cover. It

is secured by two screws underneath and hinged at the top, allowing complete removal. If the beacon option is

fitted, a cable-loom is attached; this may be unplugged at either end, but it may be easier to detach/reattach

the plug connecting to the main unit.

To access the Fault Relay and other I/O Module connections, the front panel must be dropped down by

loosening the two knurled screw fixings at either side.

As shown in the diagrams in Section 3.1, knock-out cable entry points are provided at the top and left-hand

side of the metal back box. Where the field wiring to the unit is not via conduit tubing, strain-relief type cable

glands of a suitable size to fit the 25 mm diameter holes must be fitted to all used cable entry holes. These

cable glands shall be fitted so as to provide strain relief and ensure that the protective earth connection (where

used) is the last conductor to take any strain.

External Power Supply Connection

VFT detectors are powered by an external 24 VDC power supply.

The power supply cable cores should be fitted individually with ferrite cores, close to the cable gland inside the

equipment case. To fit the cables with the ferrite cores, insert the 24V and 0V conductors through the ferrite

cores and wrap around once to provide maximum effectiveness.

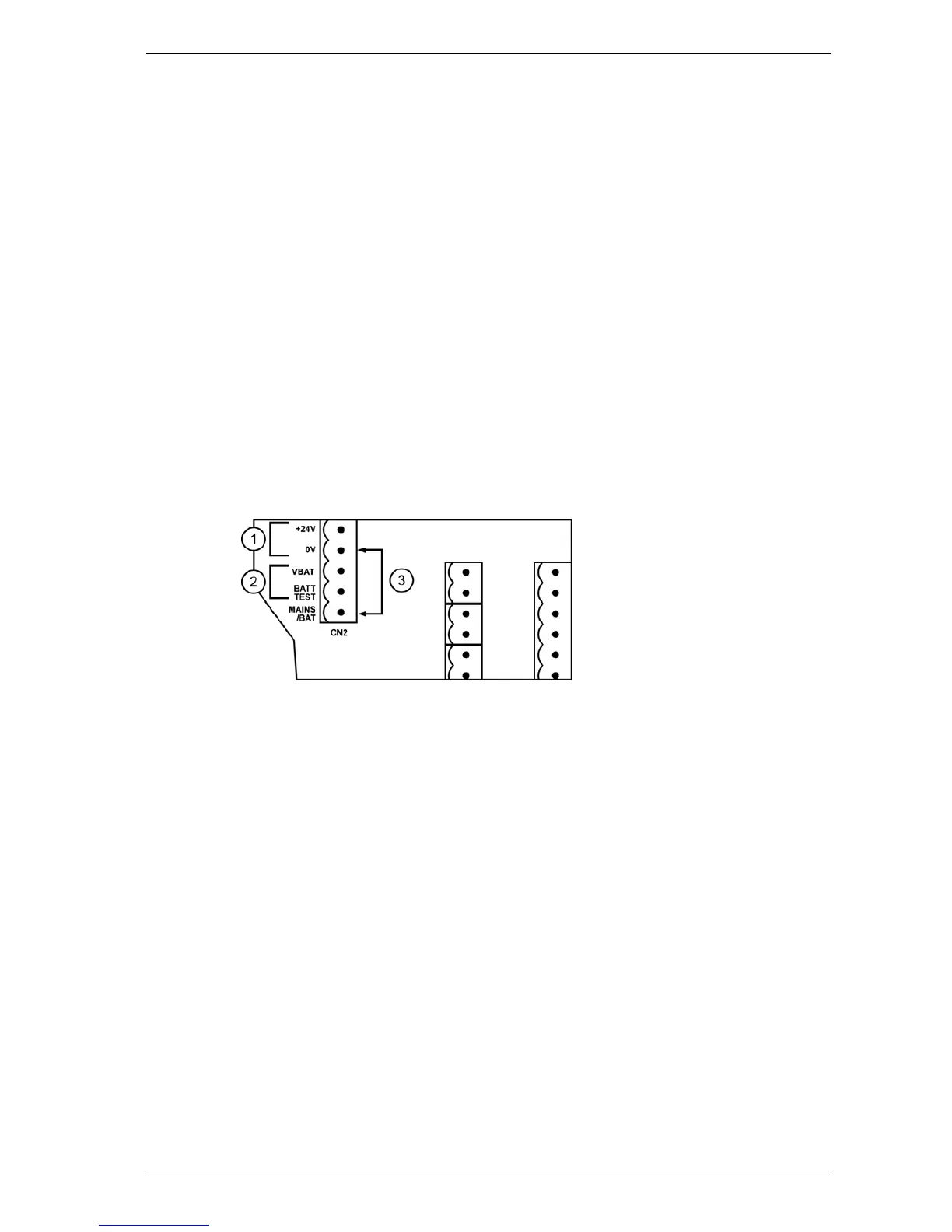

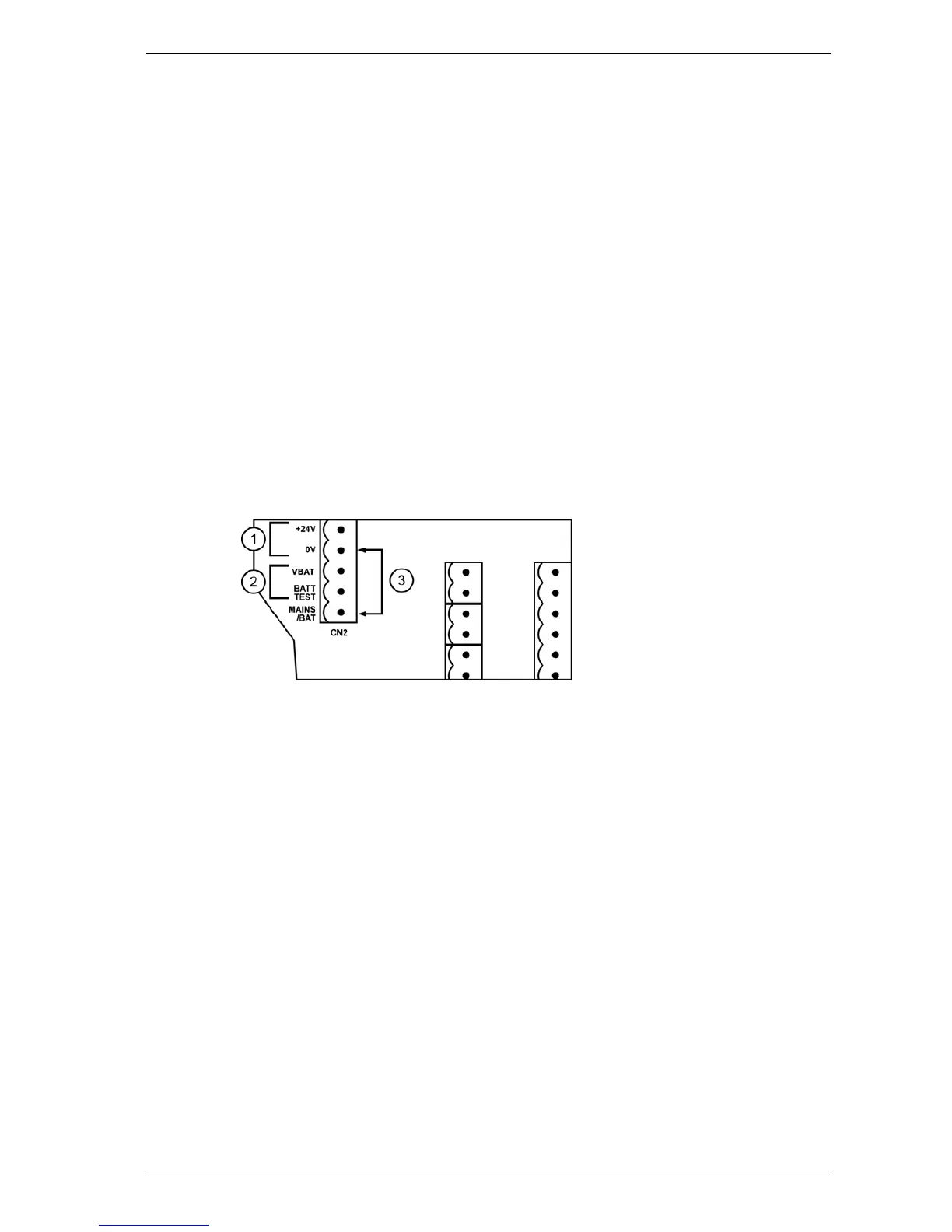

Connect the 24 VDC power supply to the 5-way connector (CN2) on the I/O board under the control panel as

shown in Figure 3-2.

1. External Power

Supply

2. No Connection

3. Link

Figure 3-2: 24 VDC connection for VFT Detectors

The MAINS/BAT terminal must be linked to 0 V. Failure to do so may result in a Mains Fault. The VBAT and

BATT TEST terminals should be left unconnected.

Ensure that in the Configuration menu, the STANDBY parameter is set to 0. For more information about

Configuration mode, refer to Section 5.3.4.

For use in UL/ULCFire Alarm Application, refer to Appendix F.

Grounding and Fuse Protection

An M5 chassis earthing stud is provided for the grounding of the unit using a suitable gauge of wire or earth

braiding (0.75 mm² minimum) to a primary earth point (i.e. copper water pipe or an earth-stake etc.). This

chassis earth should be connected on all DC powered installations.

Loading...

Loading...