XYZ Bed Mill Safety, Installation, Maintenance, Service & Parts List Manual

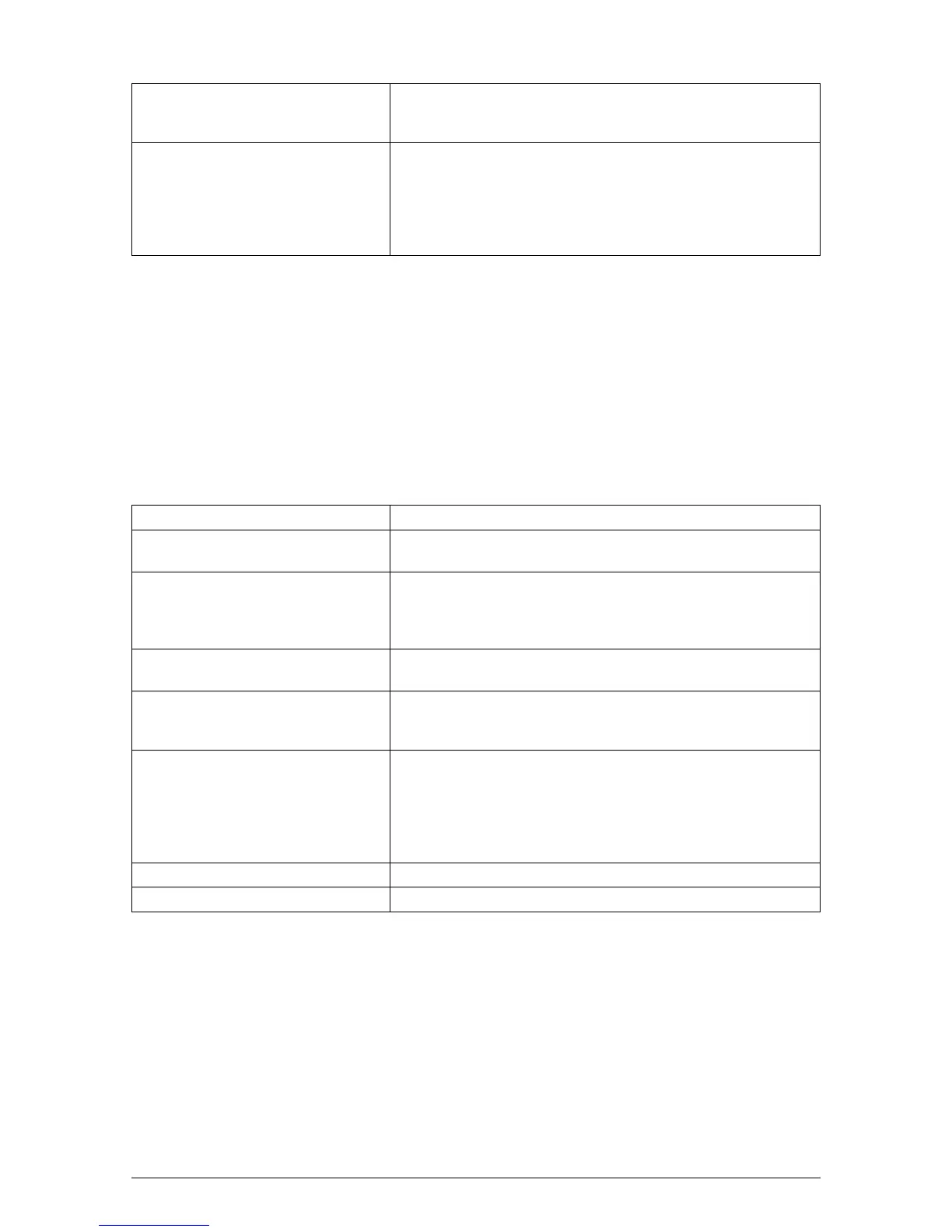

Calibration or Backlash problem

Recalibrate the machine. Reset the Backlash. Check

Repeatability and Positional Accuracy. See Calibration &

Backlash Constants section.

Binding in the Drive Train

Check Repeatability using the Repeatability and Positional

Accuracy procedure. Check the torque reading of the Drive

Train. Step by step, carefully inspect the Drive Train for any

binding. It may be necessary to disassemble and then

reassemble the Drive Train. See Mechanical Drive Train (X, Y)

Section 4.2

3.2.5 Vibration in Motion

While axis is moving there is vibration or noise coming from the X or Y-axis.

Do the following Service Codes and procedures:

Code 11 Measure's the backlash in the system. Only used on machines with Dual Feedback

systems

Code 12 Feed Forward Constant. High feed forward constants will cause an unstable servo

system

Code 127 Measure's the backlash in the system. Only used on machines with no Dual Feedback

Code 128 Enter backlash compensation

Code 123 Calibrate

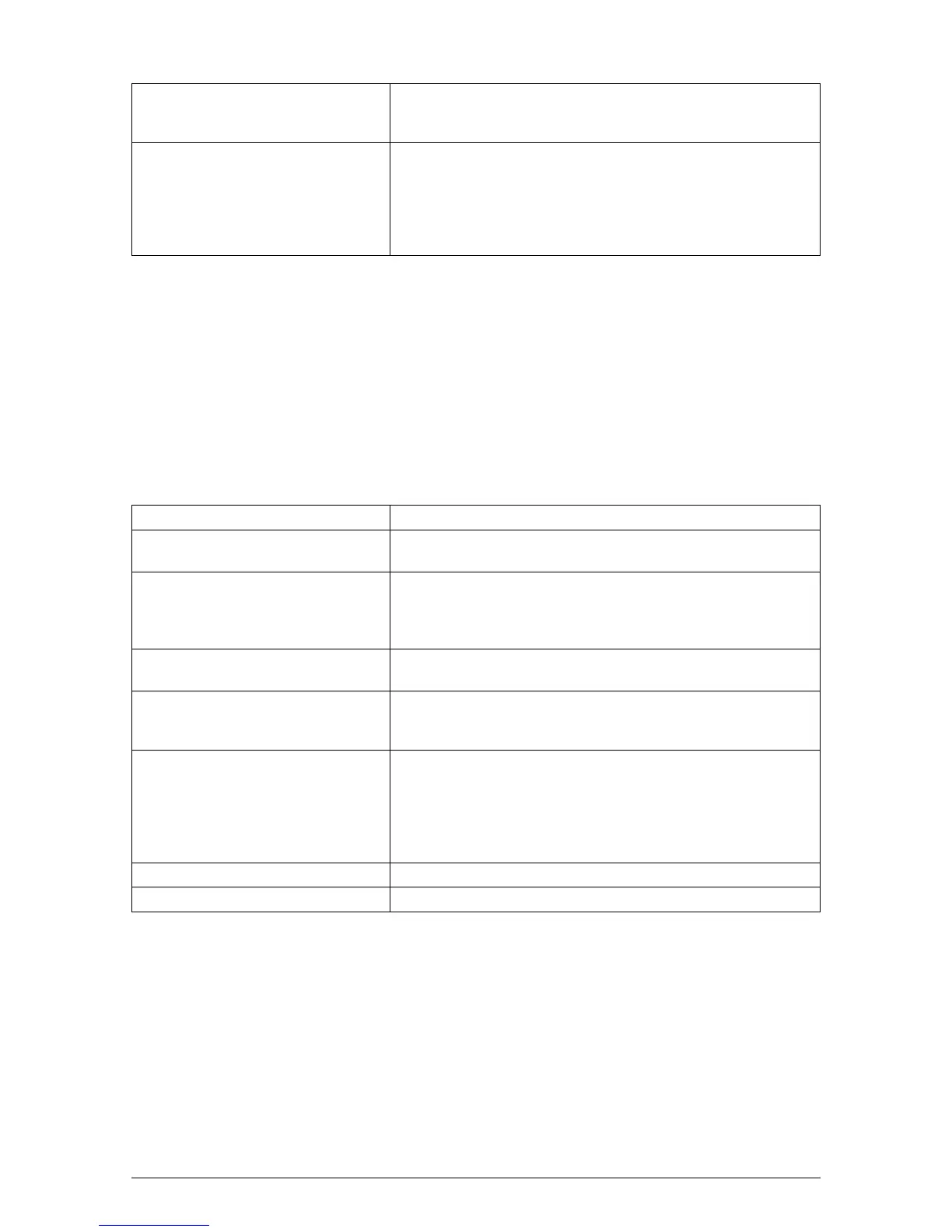

Too much backlash entered in Code

128 or Code 11.

Recheck the machines backlash.

Inadequate or no Lubrication to

Ballscrews and Way surfaces

Make sure all the Way surfaces are getting proper lubrication. If

not, check to make sure that the lube pump is functioning

properly. Also check for any pinched or blocked oil lines. See

Lubrication section

X, Y, and Z-axis Gibs are not

adjusted properly

Check the adjustment of the X, Y, and Z-axis Gibs using the X,

Y, and Z-axis Gib adjustment procedures.

Gibs not making good contact.

Pull gibs out and mark with a blue die to check where the gibs

are making contact. It is recommended that the gibs uniformly

contact at least 80% of the surface.

Binding or looseness in the Drive

Train

Check Repeatability using the Repeatability and Positional

Accuracy procedure. Check the torque reading of the Drive

Train. Step by step, carefully inspect the Drive Train for any

binding or looseness. It may be necessary to disassemble and

then reassemble the Drive Train. See Mechanical Drive Train (X,

Y) Section 4.2

Axis Motor belt too tight.

Misalignment of ball screw

See Mechanical Drive Train (X, Y) Section 4.2

3.2.6 Searching Axis

The handwheels are slowly turning back and forth when the servos are engaged. Several thousandths of

motion are observed on the vernier dial and the frequency is one cycle every couple of seconds.

Do the following Service Code and procedures:

Code 11 Measures backlash in system. (Used only with glass scales and sensors.)

Code 12 Sets a feed forward power constant to drive axis motors

Code 128 Backlash compensation on single feedback machines

Loading...

Loading...